- Home Page

- Company Profile

-

Our Products

- Rubber Rollers

- Carbon Fiber Roller

- Film Plant Rubber Rolls

- Film Plant Roller

- Rubber Groove Spreader Roller

- Lamination Roller

- Etching Roller

- Textile Printing Rubber Roller

- Cork Rollers

- Rotogravure Printing Rubber Rollers

- Godded Roller

- Polyurethane Rubber Roller

- Rubber Coated Rollers

- Rubber Grooved Spreader Rollers

- Quick Change Sleeve Roller

- Rotogravure Printing Roller

- Lamination Rubber Rollers

- Rubber Roller For Foil

- Rubber Spreader Roller

- Rubber Roller for Leather

- Industrial Rubber Roller

- Flexo Gravure Printing Rollers

- Flexographic Rubber Roller

- Rubber Roller

- Damping Rubber Roller

- PU Rubber Roller

- Sucker Muller Rubber Roller

- Impression Rubber Roller

- Solvent Based Lamination Rubber Roller

- Ebonite Rubber Rollers

- Adhesive Coating Rubber Roller

- Intermediate Rubber Roller

- Hollow Rubber Roller

- VMCH Coating Rubber Roller

- Nitrile Rubber Rollers

- Printing Rubber Roller

- Rubber Roller for Tyre-tube

- Hypalon Rubber Rollers

- Tap Line Rubber Roller

- Chemical Resistance Rubber Roller

- EPDM Rubber Rollers

- BOPP Film Plant Rubber Roller

- Jockey Rubber Roller

- Raffia Machine Rubber Rollers

- Solventless Lamination Rubber Roller

- Packaging Rubber Roller

- Industrial Silicone Rubber Roller

- Adhesive Applicator Silicone Rubber Roller

- Hot Stamping Silicone Rubber Roller

- Printing Rubber Rollers

- Rubber Roller PTFE Coated

- Rubber Roller Ptfe Coated

- Flexo Gravure Printing Rubber Roller

- Synthetic Rubber Roller

- Air Shafts

- Air Shaft

- Carbon Fiber Air Shaft

- Quick Lock Shaft

- Core Shaft

- Air Expanding Shafts

- Leaf Type Air Expandable Shaft

- Lug Type Air Expandable Shaft

- Multi Bladder Shaft

- Multi Tube Air Shaft

- Multi Tube Shaft

- Ball Type Quick Lock Shafts

- Metalizer Air Shaft

- Core Air Shaft

- Cantilever Air Shaft

- Industrial Air Shaft

- Mechanical Air Expandable Shaft

- Rubber Expander Roller

- Aluminium or Wooden Slat Expanders

- Rubber Load Roller

- Polyband Expander Roller

- Rubber Expander Roller for Textile Industry

- Textile Rubber Expander Roller

- Curve Bar Expander Roller

- Rubber Expander Roller for Paper Industry

- Liquid Ammonia Expander Roller

- Rubber Expander Roller

- Industrial Textile Expanders

- Pop Reel Rubber Expander Roller

- Liquid Ammonia Rubber Expander Roller

- Rubber Expander Roller For Packaging Industry

- Curved Bar Rubber Expander Roller

- Variable bow roller

- Bow Rollers

- PU Roller

- Safety Chucks

- Embossing Roller

- PTFE Coated Roller

- PTFE Sleeve Coated Roller for Paper Industries

- Rubber Expander Roller with FEP PTFE Sleeve

- Rubber Expander With FEP PTFE Sleeve

- PTFE Expander Roller

- PTFE Coated Rubber Expander

- PTFE Sleeve Expander Roller

- PTFE Sleeve Coated Roller

- PTFE Sleeve Coated Roller For Paper Industries

- PTFE Sleeve Coated Bow Roller

- Air Expanding Shaft

- Hard Chrome Plated Roller

- Steel Rollers

- Banana Roller

- Core Holding Devices

- Air Chuck

- Differential Shafts

- Nip Rollers

- Anilox Roller

- Lock Shafts

- Aluminium Guide Rollers

- Lamination Rubber Roller

- Silicone Rubber Roller

- Rubber Sleeves

- Industrial Rollers

- Industrial Shafts

- Rubber Rollers

-

Applications

- Rubber Roller for Leather Industries

- Rubber Roller for Plastic Industries

- Rubber Roller for Textile Industries

- Rubber Roller for Paper Industries

- Rubber Roller for Metal Industries

- Quality

- Rubber Roller for Packaging Industries

- Rubber Roller for Tyre-tube

- Rubber Roller for Wallpaper Industries

- Infrastructure & Facilities

- Exports

- Infrastructure & Facilities

- Exports

- Contact Us

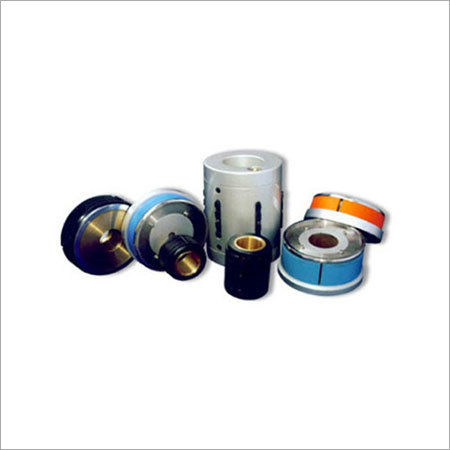

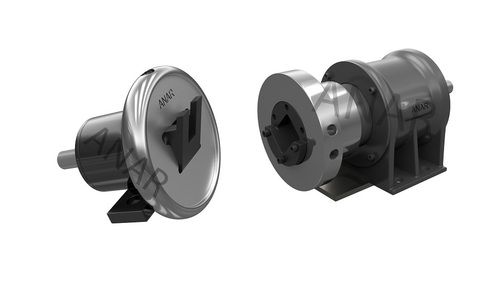

Core Chuck

25000.00 INR/Piece

Product Details:

- Product Type Core Chuck

- General Use Holding and gripping cores for winding/unwinding operations

- Material Other

- Type Mechanical Expansion Chuck

- Capacity Depending on core size, commonly from 3 to 12 diameters

- Weight (kg) Varies as per design; typically 4 to 15 kg

- Computerized No

- Click to View more

X

Core Chuck Price And Quantity

- 1 Piece

- 25000.00 INR/Piece

Core Chuck Product Specifications

- 3 or 4 (depending on model)

- No

- No

- High grip strength, robust construction, easy installation, suitable for high-speed operation

- Varies by capacity standard: approx. 200mm 150mm 150mm

- Holding and gripping cores for winding/unwinding operations

- Varies as per design; typically 4 to 15 kg

- No

- Other

- Metallic Silver

- Core Chuck

- Mechanical Expansion Chuck

- Depending on core size, commonly from 3 to 12 diameters

- Manual Operation

Core Chuck Trade Information

- 500 Piece Per Month

- 21 Days

Product Description

Experience the fresh standard in core gripping with our Highly Recommended Core Chuck. Offered at a competitive Price Cut, this astounding device features a gorgeous surface finishNickel Plated or Chrome Platedfor transcendent corrosion resistance. With robust mechanical expanding wedge or segment grip mechanisms, it secures paper, film, foil, textile, plastic, and more. Designed for flange or shaft mounting, it operates up to 3000 RPM, fits cores from paper to composite metals, and is suitable for dry or humid sites. Custom sizes, easy installation, and low-maintenance make it a top choice among exporters, manufacturers, and service providers in India.

Application Surface Excellence, Site of Application, and Material Feature

Our Core Chuck boasts a metallic silver finish, ensuring both attractiveness and durability in professional environments. Highly adaptable, it is suitable for use in paper, film, foil, textile, plastic, and printing industries. Its surface finisheither Nickel or Chrome platednot only enhances its corrosion resistance but also enables transcendent performance in both dry and humid contexts. The robust mechanical grip ensures optimal compatibility with paper, plastic, metal, and composite cores, making it an ideal fit across diverse applications.

Supply Ability, Goods Transport, and Export Market Credentials

We supports bulk and customized supply with reliable freight and goods transport solutions, catering to a thriving export market. Our products are shipped from major Indian FOB ports, ensuring prompt and secure delivery. We offer List price quotations and adhere to international standards, supported by certifications that guarantee quality. With efficient production capability and robust logistics, we stand out as a preferred exporter, manufacturer, supplier, and service provider for Core Chucks worldwide.

Application Surface Excellence, Site of Application, and Material Feature

Our Core Chuck boasts a metallic silver finish, ensuring both attractiveness and durability in professional environments. Highly adaptable, it is suitable for use in paper, film, foil, textile, plastic, and printing industries. Its surface finisheither Nickel or Chrome platednot only enhances its corrosion resistance but also enables transcendent performance in both dry and humid contexts. The robust mechanical grip ensures optimal compatibility with paper, plastic, metal, and composite cores, making it an ideal fit across diverse applications.

Supply Ability, Goods Transport, and Export Market Credentials

We supports bulk and customized supply with reliable freight and goods transport solutions, catering to a thriving export market. Our products are shipped from major Indian FOB ports, ensuring prompt and secure delivery. We offer List price quotations and adhere to international standards, supported by certifications that guarantee quality. With efficient production capability and robust logistics, we stand out as a preferred exporter, manufacturer, supplier, and service provider for Core Chucks worldwide.

FAQs of Core Chuck:

Q: How does the surface finish of the Core Chuck enhance its durability?

A: The Nickel Plated or Chrome Plated surface finish on the Core Chuck offers astounding corrosion resistance, maintaining its performance and longevity even in humid or demanding industrial environments.Q: What industries can benefit from using this Core Chuck?

A: This Core Chuck is designed for use in a broad spectrum of industries such as paper, film, foil, textile, plastic, and printing, making it a versatile solution for winding and unwinding in various production lines.Q: When is it necessary to lubricate the Core Chuck?

A: Periodic lubrication is recommended to ensure the smooth operation and maintenance of the Core Chuck, helping it achieve its full life expectancy and maintain high grip strength.Q: Where can the Core Chuck be installed?

A: It can be installed via flange or shaft mounting, providing flexible application at any site where core gripping for winding or unwinding is required, be it dry or humid environments.Q: What core sizes and materials is the Core Chuck compatible with?

A: This model supports a range of core diameters from 3 to 12 inches and is compatible with paper, plastic, metal, and composite cores, offering extraordinary adaptability.Q: How can replacement parts or custom sizes be ordered?

A: Replacement parts and custom sizes are available upon request. Clients can contact the manufacturer or supplier directly to specify requirements or obtain tailored solutions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email