- Home Page

- Company Profile

-

Our Products

- Rubber Rollers

- Cork Rollers

- Textile Printing Rubber Roller

- Lamination Roller

- Film Plant Roller

- Etching Roller

- Carbon Fiber Roller

- Film Plant Rubber Rolls

- Rubber Groove Spreader Roller

- Rubber Coated Rollers

- Godded Roller

- Rotogravure Printing Rubber Rollers

- Polyurethane Rubber Roller

- Rubber Grooved Spreader Rollers

- Quick Change Sleeve Roller

- Rotogravure Printing Roller

- Rubber Roller For Foil

- Lamination Rubber Rollers

- Rubber Roller for Leather

- Rubber Spreader Roller

- Flexo Gravure Printing Rollers

- Industrial Rubber Roller

- Flexographic Rubber Roller

- Rubber Roller

- Damping Rubber Roller

- PU Rubber Roller

- Impression Rubber Roller

- Sucker Muller Rubber Roller

- Solvent Based Lamination Rubber Roller

- Ebonite Rubber Rollers

- Adhesive Coating Rubber Roller

- Intermediate Rubber Roller

- Hollow Rubber Roller

- VMCH Coating Rubber Roller

- Nitrile Rubber Rollers

- Printing Rubber Roller

- Rubber Roller for Tyre-tube

- Hypalon Rubber Rollers

- Tap Line Rubber Roller

- Chemical Resistance Rubber Roller

- EPDM Rubber Rollers

- BOPP Film Plant Rubber Roller

- Jockey Rubber Roller

- Raffia Machine Rubber Rollers

- Solventless Lamination Rubber Roller

- Packaging Rubber Roller

- Industrial Silicone Rubber Roller

- Adhesive Applicator Silicone Rubber Roller

- Hot Stamping Silicone Rubber Roller

- Printing Rubber Rollers

- Rubber Roller PTFE Coated

- Rubber Roller Ptfe Coated

- Flexo Gravure Printing Rubber Roller

- Synthetic Rubber Roller

- Air Shafts

- Carbon Fiber Air Shaft

- Air Shaft

- Quick Lock Shaft

- Core Shaft

- Air Expanding Shafts

- Leaf Type Air Expandable Shaft

- Lug Type Air Expandable Shaft

- Multi Bladder Shaft

- Multi Tube Air Shaft

- Multi Tube Shaft

- Ball Type Quick Lock Shafts

- Metalizer Air Shaft

- Core Air Shaft

- Cantilever Air Shaft

- Industrial Air Shaft

- Mechanical Air Expandable Shaft

- Rubber Expander Roller

- Aluminium or Wooden Slat Expanders

- Rubber Load Roller

- Polyband Expander Roller

- Rubber Expander Roller for Textile Industry

- Textile Rubber Expander Roller

- Curve Bar Expander Roller

- Rubber Expander Roller for Paper Industry

- Liquid Ammonia Expander Roller

- Rubber Expander Roller

- Industrial Textile Expanders

- Pop Reel Rubber Expander Roller

- Liquid Ammonia Rubber Expander Roller

- Rubber Expander Roller For Packaging Industry

- Curved Bar Rubber Expander Roller

- Variable bow roller

- Bow Rollers

- PU Roller

- Safety Chucks

- Embossing Roller

- PTFE Coated Roller

- PTFE Sleeve Coated Roller for Paper Industries

- Rubber Expander Roller with FEP PTFE Sleeve

- Rubber Expander With FEP PTFE Sleeve

- PTFE Expander Roller

- PTFE Coated Rubber Expander

- PTFE Sleeve Expander Roller

- PTFE Sleeve Coated Roller

- PTFE Sleeve Coated Roller For Paper Industries

- PTFE Sleeve Coated Bow Roller

- Air Expanding Shaft

- Hard Chrome Plated Roller

- Steel Rollers

- Banana Roller

- Core Holding Devices

- Air Chuck

- Differential Shafts

- Nip Rollers

- Anilox Roller

- Lock Shafts

- Aluminium Guide Rollers

- Lamination Rubber Roller

- Silicone Rubber Roller

- Rubber Sleeves

- Industrial Rollers

- Industrial Shafts

- Rubber Rollers

-

Applications

- Rubber Roller for Leather Industries

- Rubber Roller for Plastic Industries

- Rubber Roller for Textile Industries

- Rubber Roller for Paper Industries

- Rubber Roller for Metal Industries

- Quality

- Rubber Roller for Packaging Industries

- Rubber Roller for Tyre-tube

- Rubber Roller for Wallpaper Industries

- Infrastructure & Facilities

- Exports

- Infrastructure & Facilities

- Exports

- Contact Us

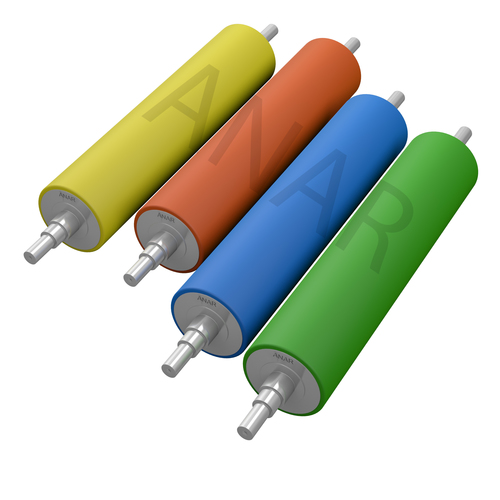

Packaging Rubber Roller

8000.00 - 28500.00 INR/Piece

Product Details:

- Condition New

- Structure Cylindrical core with seamless rubber coating

- Rubber Type High-grade synthetic rubber

- Handle Material Steel

- Handle Color Silver

- Weight 2.5 kg

- Attributes Excellent abrasion resistance, smooth operation, suitable for high-speed packaging machines

- Click to View more

X

Packaging Rubber Roller Price And Quantity

- 8000.00 - 28500.00 INR/Piece

- 1 Piece

Packaging Rubber Roller Product Specifications

- Excellent abrasion resistance, smooth operation, suitable for high-speed packaging machines

- Silver

- Cylindrical core with seamless rubber coating

- High-grade synthetic rubber

- 2.5 kg

- New

- Steel

Packaging Rubber Roller Trade Information

- Mundra

- 500 Piece Per Month

- 21 Days

- Standard

- All India

- ISO 9001 & CE

Product Description

Packaging Rubber Roller provided by us, is utilized in a range of manufacturing processes and is used for a variety of reasons. This roller is used in the production of textiles, film, sheet, paper, and coiled metal, among other things. Besides, this roller has found use in a variety of applications that demand a high level of contact and holding friction. Packaging Rubber Roller is very easy to install as well as simple to use. In addition, the industrial product can be used in material processing applications that demand a gentle touch.

Technical Details

Material | Polyurethane Rubber |

Length | Up to 8500 mm |

Diameter | Upto 600 mm |

I Deal In | New Only |

Usage/Application | Industrial |

Brand | Anar |

Precision Engineering for Optimal Performance

Crafted with a cylindrical core of mild or stainless steel, each packaging rubber roller is precision-ground for a smooth finish, ensuring vibration-free and consistent operation. The seamless synthetic rubber coating allows for uniform pressure distribution, making it suitable for high-speed machines in packaging, printing, laminating, and converting industries.

Built to Withstand Challenging Conditions

Our rollers are designed to resist temperatures from -10C up to +80C, and their anti-static, chemical-resistant properties ensure long-term reliability in demanding industrial environments. Each roller is inspected for seamless coating integrity and uniform surface qualities, maximizing equipment uptime and product quality.

FAQs of Packaging Rubber Roller:

Q: How are the packaging rubber rollers installed in machinery?

A: Packaging rubber rollers can be mounted using either a flange or shaft mounting system, allowing for secure integration with various machines such as packaging, printing, or laminating units. Each roller is engineered for straightforward installation to minimize downtime.Q: What are the benefits of using high-grade synthetic rubber for these rollers?

A: High-grade synthetic rubber provides exceptional abrasion resistance, smooth operation at high speeds, and effective anti-static and chemical resistance. This prolongs roller life, ensures consistent product quality, and reduces maintenance costs.Q: When should I replace my packaging rubber roller?

A: It is advisable to replace the roller if you notice significant wear, reduced performance, or damage to the rubber coating. Regular inspection is recommended, especially in high-speed or heavy-duty applications, to ensure optimal efficiency.Q: Where are these rubber rollers commonly used?

A: These packaging rubber rollers are widely used in packaging machines, printing equipment, laminators, and converting machinery due to their versatility, durability, and smooth operation. Industries served include manufacturing, food processing, and logistics.Q: What is the manufacturing process for these rollers?

A: The process starts with fabricating a mild or stainless steel core, followed by precision grinding. A seamless layer of high-grade synthetic rubber is then applied and cured for maximum adhesion and durability. Each roller undergoes quality checks for surface finish and hardness.Q: How do the rollers perform under varying temperatures?

A: Designed to operate reliably from -10C to +80C, these rollers maintain their structural integrity and surface properties, making them suitable for a range of environmental conditions typical of industrial applications.Q: What color and surface finish options are available?

A: Standard rollers come in black, but color customization is available upon request. All rollers feature a smooth, precision-ground surface for seamless operation in high-speed machines.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email