- Home Page

- Company Profile

-

Our Products

- Rubber Rollers

- Textile Printing Rubber Roller

- Cork Rollers

- Film Plant Roller

- Carbon Fiber Roller

- Film Plant Rubber Rolls

- Rubber Groove Spreader Roller

- Etching Roller

- Lamination Roller

- Godded Roller

- Rubber Grooved Spreader Rollers

- Rotogravure Printing Rubber Rollers

- Polyurethane Rubber Roller

- Rubber Coated Rollers

- Quick Change Sleeve Roller

- Rotogravure Printing Roller

- Rubber Roller For Foil

- Lamination Rubber Rollers

- Rubber Spreader Roller

- Rubber Roller for Leather

- Flexo Gravure Printing Rollers

- Industrial Rubber Roller

- Flexographic Rubber Roller

- Rubber Roller

- PU Rubber Roller

- Damping Rubber Roller

- Sucker Muller Rubber Roller

- Impression Rubber Roller

- Solvent Based Lamination Rubber Roller

- Ebonite Rubber Rollers

- Adhesive Coating Rubber Roller

- Intermediate Rubber Roller

- Hollow Rubber Roller

- VMCH Coating Rubber Roller

- Nitrile Rubber Rollers

- Printing Rubber Roller

- Rubber Roller for Tyre-tube

- Hypalon Rubber Rollers

- Tap Line Rubber Roller

- Chemical Resistance Rubber Roller

- EPDM Rubber Rollers

- BOPP Film Plant Rubber Roller

- Jockey Rubber Roller

- Raffia Machine Rubber Rollers

- Solventless Lamination Rubber Roller

- Packaging Rubber Roller

- Industrial Silicone Rubber Roller

- Adhesive Applicator Silicone Rubber Roller

- Hot Stamping Silicone Rubber Roller

- Printing Rubber Rollers

- Rubber Roller PTFE Coated

- Rubber Roller Ptfe Coated

- Flexo Gravure Printing Rubber Roller

- Synthetic Rubber Roller

- Air Shafts

- Carbon Fiber Air Shaft

- Air Shaft

- Quick Lock Shaft

- Core Shaft

- Air Expanding Shafts

- Leaf Type Air Expandable Shaft

- Lug Type Air Expandable Shaft

- Multi Bladder Shaft

- Multi Tube Air Shaft

- Multi Tube Shaft

- Ball Type Quick Lock Shafts

- Metalizer Air Shaft

- Core Air Shaft

- Cantilever Air Shaft

- Industrial Air Shaft

- Mechanical Air Expandable Shaft

- Rubber Expander Roller

- Aluminium or Wooden Slat Expanders

- Rubber Load Roller

- Polyband Expander Roller

- Rubber Expander Roller for Textile Industry

- Textile Rubber Expander Roller

- Curve Bar Expander Roller

- Rubber Expander Roller for Paper Industry

- Rubber Expander Roller

- Liquid Ammonia Expander Roller

- Pop Reel Rubber Expander Roller

- Industrial Textile Expanders

- Liquid Ammonia Rubber Expander Roller

- Rubber Expander Roller For Packaging Industry

- Curved Bar Rubber Expander Roller

- Variable bow roller

- Bow Rollers

- PU Roller

- Safety Chucks

- Embossing Roller

- PTFE Coated Roller

- PTFE Sleeve Coated Roller for Paper Industries

- Rubber Expander Roller with FEP PTFE Sleeve

- Rubber Expander With FEP PTFE Sleeve

- PTFE Expander Roller

- PTFE Coated Rubber Expander

- PTFE Sleeve Expander Roller

- PTFE Sleeve Coated Roller

- PTFE Sleeve Coated Roller For Paper Industries

- PTFE Sleeve Coated Bow Roller

- Air Expanding Shaft

- Hard Chrome Plated Roller

- Steel Rollers

- Banana Roller

- Core Holding Devices

- Air Chuck

- Differential Shafts

- Nip Rollers

- Anilox Roller

- Lock Shafts

- Aluminium Guide Rollers

- Lamination Rubber Roller

- Silicone Rubber Roller

- Rubber Sleeves

- Industrial Rollers

- Industrial Shafts

- Rubber Rollers

-

Applications

- Rubber Roller for Leather Industries

- Rubber Roller for Plastic Industries

- Rubber Roller for Textile Industries

- Rubber Roller for Paper Industries

- Rubber Roller for Metal Industries

- Quality

- Rubber Roller for Packaging Industries

- Rubber Roller for Tyre-tube

- Rubber Roller for Wallpaper Industries

- Infrastructure & Facilities

- Exports

- Infrastructure & Facilities

- Exports

- Contact Us

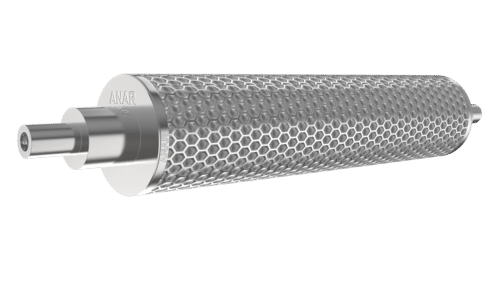

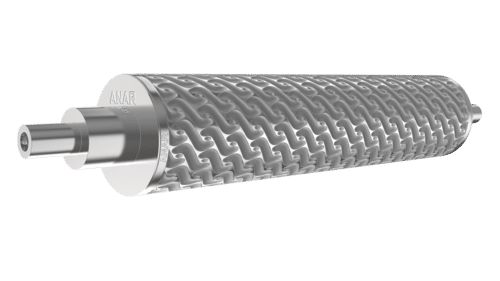

Embossing Roller

18000.00 - 48500.00 INR/Piece

Product Details:

- Diameter 50 mm to 400 mm

- Capacity Customizable as per requirement

- Material Hardened Steel / Stainless Steel / Brass

- Dimensions Customized Length and Pattern

- Technique CNC / Laser Engraving

- Standard ISO 9001:2015

- Belt Width Up to 2500 mm

- Click to View more

X

Embossing Roller Price And Quantity

- 18000.00 - 48500.00 INR/Piece

- 1 Piece

Embossing Roller Product Specifications

- 50 mm to 400 mm

- Customized Length and Pattern

- Hardened Steel / Stainless Steel / Brass

- CNC / Laser Engraving

- Corrosion Resistant, Precision Engraved Design, Long Service Life

- Up to 2500 mm

- Customizable as per requirement

- ISO 9001:2015

Embossing Roller Trade Information

- Ahmedabad

- 5000 Piece Per Month

- 21 Days

- Standard

- Australia, Central America, South America, Western Europe, Middle East, Eastern Europe, Asia, North America, Africa

- All India

- ISO 9001 & CE

Product Description

Technical specification

Uses | Paper Industry,Plastic Industry,Leangth Industry,Sheet Metal Industry,Textile Industry etc. |

Model | ART-8003 |

Brand | Anar |

Capacity | Length upto 6 Mtr. |

Color | Siliver |

Material | M.S |

Details

- Forging Tolerance: +/-0.2 mm

- Molding Technics: Pressure Casting

- Material: Steel

Versatile Pattern Choices

Choose from a wide array of patterns, including geometric, wooden, textile, leather, or design your own. Precision engraving ensures crisp, repeatable results for every requirement across diverse industries.

Durable Materials & Coatings

Manufactured using seamless steel tubes and available in hardened steel, stainless steel, or brass, these rollers are finished with chrome, nickel, or non-stick coatings. The robust build guarantees corrosion resistance and extended service life.

Customized for Every Application

Rollers are tailored by size, length, belt width, and mounting type to suit your process precisely. From small to large diameters (50 mm to 400 mm) and roll lengths up to 4000 mm, customization options meet the demands of any production line.

FAQs of Embossing Roller:

Q: How is the embossing pattern created on the roller?

A: The embossing patterns are crafted using advanced CNC and laser engraving techniques, which allow for highly detailed and precise designs that can be geometric, wooden, textile, leather, or fully customized based on customer requirements.Q: What industries commonly use these embossing rollers?

A: Embossing rollers are widely utilized in the paper, leather, textile, vinyl, film, and foil industries due to their ability to emboss intricate designs efficiently onto various materials.Q: When should you opt for mirror polished versus matt surface finishes?

A: Mirror polished rollers are preferred when a high-gloss, smooth finish is required, while matt finish rollers are better suited for subtle, textured results. Selection depends on desired aesthetics and production needs.Q: Where are the rollers manufactured and supplied from?

A: These embossing rollers are engineered, manufactured, exported, and supplied by a certified ISO 9001:2015 manufacturer based in India, ensuring adherence to global quality standards.Q: What is the cleaning and maintenance process for embossing rollers?

A: Embossing rollers are designed for low maintenance and are easy to clean and service due to their corrosion-resistant coatings. Regular gentle cleaning with appropriate solvents keeps them in optimal condition.Q: How does the core material and coating contribute to roller performance?

A: A seamless steel tube core offers durability and stability, while chrome plated, nickel plated, or non-stick coatings enhance corrosion resistance, facilitate cleaning, and prolong the service life of the roller.Q: What are the benefits of precision engraved embossing rollers?

A: Precision engraving ensures high repeatability and accuracy, resulting in consistent pattern quality. Coupled with robust construction and specialized coatings, these rollers deliver excellent performance and longevity in industrial environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email