- Home Page

- Company Profile

-

Our Products

- Rubber Rollers

- Textile Printing Rubber Roller

- Cork Rollers

- Film Plant Roller

- Carbon Fiber Roller

- Film Plant Rubber Rolls

- Rubber Groove Spreader Roller

- Etching Roller

- Lamination Roller

- Godded Roller

- Rubber Grooved Spreader Rollers

- Rotogravure Printing Rubber Rollers

- Polyurethane Rubber Roller

- Rubber Coated Rollers

- Quick Change Sleeve Roller

- Rotogravure Printing Roller

- Rubber Roller For Foil

- Lamination Rubber Rollers

- Rubber Spreader Roller

- Rubber Roller for Leather

- Flexo Gravure Printing Rollers

- Industrial Rubber Roller

- Flexographic Rubber Roller

- Rubber Roller

- PU Rubber Roller

- Damping Rubber Roller

- Sucker Muller Rubber Roller

- Impression Rubber Roller

- Solvent Based Lamination Rubber Roller

- Ebonite Rubber Rollers

- Adhesive Coating Rubber Roller

- Intermediate Rubber Roller

- Hollow Rubber Roller

- VMCH Coating Rubber Roller

- Nitrile Rubber Rollers

- Printing Rubber Roller

- Rubber Roller for Tyre-tube

- Hypalon Rubber Rollers

- Tap Line Rubber Roller

- Chemical Resistance Rubber Roller

- EPDM Rubber Rollers

- BOPP Film Plant Rubber Roller

- Jockey Rubber Roller

- Raffia Machine Rubber Rollers

- Solventless Lamination Rubber Roller

- Packaging Rubber Roller

- Industrial Silicone Rubber Roller

- Adhesive Applicator Silicone Rubber Roller

- Hot Stamping Silicone Rubber Roller

- Printing Rubber Rollers

- Rubber Roller PTFE Coated

- Rubber Roller Ptfe Coated

- Flexo Gravure Printing Rubber Roller

- Synthetic Rubber Roller

- Air Shafts

- Air Shaft

- Carbon Fiber Air Shaft

- Quick Lock Shaft

- Core Shaft

- Air Expanding Shafts

- Leaf Type Air Expandable Shaft

- Lug Type Air Expandable Shaft

- Multi Bladder Shaft

- Multi Tube Air Shaft

- Multi Tube Shaft

- Ball Type Quick Lock Shafts

- Metalizer Air Shaft

- Core Air Shaft

- Cantilever Air Shaft

- Industrial Air Shaft

- Mechanical Air Expandable Shaft

- Rubber Expander Roller

- Aluminium or Wooden Slat Expanders

- Rubber Load Roller

- Polyband Expander Roller

- Rubber Expander Roller for Textile Industry

- Textile Rubber Expander Roller

- Curve Bar Expander Roller

- Rubber Expander Roller for Paper Industry

- Rubber Expander Roller

- Liquid Ammonia Expander Roller

- Pop Reel Rubber Expander Roller

- Industrial Textile Expanders

- Liquid Ammonia Rubber Expander Roller

- Rubber Expander Roller For Packaging Industry

- Curved Bar Rubber Expander Roller

- Variable bow roller

- Bow Rollers

- PU Roller

- Safety Chucks

- Embossing Roller

- PTFE Coated Roller

- PTFE Sleeve Coated Roller for Paper Industries

- Rubber Expander Roller with FEP PTFE Sleeve

- Rubber Expander With FEP PTFE Sleeve

- PTFE Expander Roller

- PTFE Coated Rubber Expander

- PTFE Sleeve Expander Roller

- PTFE Sleeve Coated Roller

- PTFE Sleeve Coated Roller For Paper Industries

- PTFE Sleeve Coated Bow Roller

- Air Expanding Shaft

- Hard Chrome Plated Roller

- Steel Rollers

- Banana Roller

- Core Holding Devices

- Air Chuck

- Differential Shafts

- Nip Rollers

- Anilox Roller

- Lock Shafts

- Aluminium Guide Rollers

- Lamination Rubber Roller

- Silicone Rubber Roller

- Rubber Sleeves

- Industrial Rollers

- Industrial Shafts

- Rubber Rollers

-

Applications

- Rubber Roller for Leather Industries

- Rubber Roller for Plastic Industries

- Rubber Roller for Textile Industries

- Rubber Roller for Paper Industries

- Rubber Roller for Metal Industries

- Quality

- Rubber Roller for Packaging Industries

- Rubber Roller for Tyre-tube

- Rubber Roller for Wallpaper Industries

- Infrastructure & Facilities

- Exports

- Infrastructure & Facilities

- Exports

- Contact Us

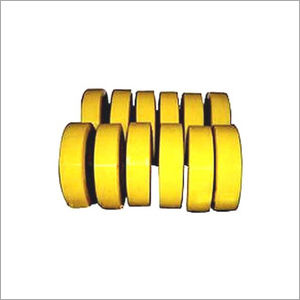

PU Support Rollers

6500.00 INR/Piece

Product Details:

- Diameter 50 mm to 500 mm

- Capacity Up to 1000 kg

- Material Polyurethane (PU), Mild Steel core

- Dimensions Customizable

- Technique Precision Moulding and Machining

- Standard DIN, ISO, or as per requirement

- Belt Width Up to 2000 mm

- Click to View more

X

PU Support Rollers Price And Quantity

- 1 Piece

- 6500.00 INR/Piece

PU Support Rollers Product Specifications

- DIN, ISO, or as per requirement

- Precision Moulding and Machining

- Up to 1000 kg

- Polyurethane (PU), Mild Steel core

- Up to 2000 mm

- Customizable

- 50 mm to 500 mm

PU Support Rollers Trade Information

- 4500 Piece Per Month

- 21 Days

Product Description

Our company manufactures high quality Support Rollers with the aid of advanced technology. These rollers, fabricated using high grade raw materials, are assured of better service life and high tensile strength. They find wide applications in various industrial and commercial areas. Our products, available in different dimensions, are tested in compliance to industry quality standards for ensuring better results.

Features of Support Rollers:

- Reasonable price

- Suitable for bearing heavy weight

Superior Durability and Performance

With a precision-moulded PU coating and a sturdy core of mild steel or stainless steel, our rollers resist oil, chemicals, and abrasion, making them ideal for harsh environments. The customizable coating thickness ensures optimal load-bearing and longevity in material handling and conveyor systems.

Comprehensive Customization Options

Our PU support rollers can be tailored to your specific needs, including color, size, hardness, and mounting options. Whether your application requires unique dimensions or adherence to DIN and ISO standards, our production flexibility ensures a perfect fit for your operations.

Wide Range of Applications

Designed for efficient performance, these rollers are suitable for use in conveyor systems, rolling mills, and a wide range of material handling setups. Their high load capacity (up to 1000 kg) and adaptability make them a dependable choice across multiple industries.

FAQs of PU Support Rollers:

Q: How are the PU support rollers manufactured and what techniques are used?

A: PU support rollers are fabricated using precision moulding and machining techniques. The polyurethane coating is applied to a core made of mild steel or stainless steel, ensuring high accuracy and durability for demanding uses.Q: What customization options are available for these support rollers?

A: We offer customization in terms of size, color (yellow, red, or as required), hardness, coating thickness (from 8 mm to 30 mm), axle bore, and mounting options to best suit your applications requirements.Q: When should I choose PU-coated rollers over traditional rollers?

A: PU-coated rollers are ideal when you need superior resistance to oil, chemicals, and abrasion. They excel in environments where traditional rubber or metal rollers may degrade more quickly due to harsh conditions.Q: Where can PU support rollers be used most effectively?

A: These rollers are best utilized in material handling systems, conveyor lines, and rolling mills. They are especially beneficial in industries requiring high load capacity and consistent performance, such as manufacturing, logistics, and steel processing.Q: What are the main benefits of using these rollers in conveyor systems?

A: The main benefits include high durability, low maintenance, and resistance to various harsh substances. Their customizable design and strong load-bearing capacity help optimize operational efficiency and reduce downtime.Q: How does the selection of core material affect roller performance?

A: Choosing between mild steel and stainless steel cores allows for optimal corrosion resistance and strength, depending on the operating conditions and load requirements of your system.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email