- Home Page

- Company Profile

-

Our Products

- Rubber Rollers

- Textile Printing Rubber Roller

- Cork Rollers

- Film Plant Roller

- Carbon Fiber Roller

- Film Plant Rubber Rolls

- Rubber Groove Spreader Roller

- Etching Roller

- Lamination Roller

- Godded Roller

- Rubber Grooved Spreader Rollers

- Rotogravure Printing Rubber Rollers

- Polyurethane Rubber Roller

- Rubber Coated Rollers

- Quick Change Sleeve Roller

- Rotogravure Printing Roller

- Rubber Roller For Foil

- Lamination Rubber Rollers

- Rubber Spreader Roller

- Rubber Roller for Leather

- Flexo Gravure Printing Rollers

- Industrial Rubber Roller

- Flexographic Rubber Roller

- Rubber Roller

- PU Rubber Roller

- Damping Rubber Roller

- Sucker Muller Rubber Roller

- Impression Rubber Roller

- Solvent Based Lamination Rubber Roller

- Ebonite Rubber Rollers

- Adhesive Coating Rubber Roller

- Intermediate Rubber Roller

- Hollow Rubber Roller

- VMCH Coating Rubber Roller

- Nitrile Rubber Rollers

- Printing Rubber Roller

- Rubber Roller for Tyre-tube

- Hypalon Rubber Rollers

- Tap Line Rubber Roller

- Chemical Resistance Rubber Roller

- EPDM Rubber Rollers

- BOPP Film Plant Rubber Roller

- Jockey Rubber Roller

- Raffia Machine Rubber Rollers

- Solventless Lamination Rubber Roller

- Packaging Rubber Roller

- Industrial Silicone Rubber Roller

- Adhesive Applicator Silicone Rubber Roller

- Hot Stamping Silicone Rubber Roller

- Printing Rubber Rollers

- Rubber Roller PTFE Coated

- Rubber Roller Ptfe Coated

- Flexo Gravure Printing Rubber Roller

- Synthetic Rubber Roller

- Air Shafts

- Carbon Fiber Air Shaft

- Air Shaft

- Quick Lock Shaft

- Core Shaft

- Air Expanding Shafts

- Leaf Type Air Expandable Shaft

- Lug Type Air Expandable Shaft

- Multi Bladder Shaft

- Multi Tube Air Shaft

- Multi Tube Shaft

- Ball Type Quick Lock Shafts

- Metalizer Air Shaft

- Core Air Shaft

- Cantilever Air Shaft

- Industrial Air Shaft

- Mechanical Air Expandable Shaft

- Rubber Expander Roller

- Aluminium or Wooden Slat Expanders

- Rubber Load Roller

- Polyband Expander Roller

- Rubber Expander Roller for Textile Industry

- Textile Rubber Expander Roller

- Curve Bar Expander Roller

- Rubber Expander Roller for Paper Industry

- Rubber Expander Roller

- Liquid Ammonia Expander Roller

- Pop Reel Rubber Expander Roller

- Industrial Textile Expanders

- Liquid Ammonia Rubber Expander Roller

- Rubber Expander Roller For Packaging Industry

- Curved Bar Rubber Expander Roller

- Variable bow roller

- Bow Rollers

- PU Roller

- Safety Chucks

- Embossing Roller

- PTFE Coated Roller

- PTFE Sleeve Coated Roller for Paper Industries

- Rubber Expander Roller with FEP PTFE Sleeve

- Rubber Expander With FEP PTFE Sleeve

- PTFE Expander Roller

- PTFE Coated Rubber Expander

- PTFE Sleeve Expander Roller

- PTFE Sleeve Coated Roller

- PTFE Sleeve Coated Roller For Paper Industries

- PTFE Sleeve Coated Bow Roller

- Air Expanding Shaft

- Hard Chrome Plated Roller

- Steel Rollers

- Banana Roller

- Core Holding Devices

- Air Chuck

- Differential Shafts

- Nip Rollers

- Anilox Roller

- Lock Shafts

- Aluminium Guide Rollers

- Lamination Rubber Roller

- Silicone Rubber Roller

- Rubber Sleeves

- Industrial Rollers

- Industrial Shafts

- Rubber Rollers

-

Applications

- Rubber Roller for Leather Industries

- Rubber Roller for Plastic Industries

- Rubber Roller for Textile Industries

- Rubber Roller for Paper Industries

- Rubber Roller for Metal Industries

- Quality

- Rubber Roller for Packaging Industries

- Rubber Roller for Tyre-tube

- Rubber Roller for Wallpaper Industries

- Infrastructure & Facilities

- Exports

- Infrastructure & Facilities

- Exports

- Contact Us

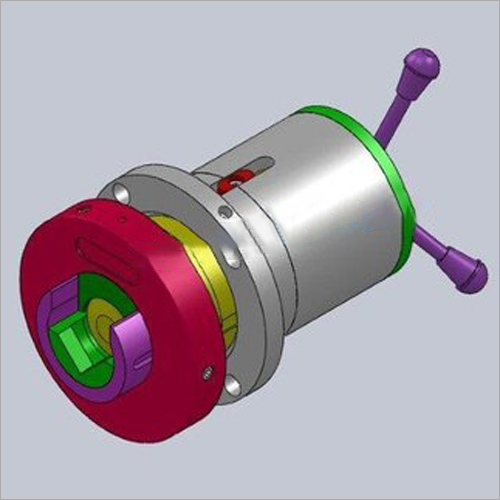

Adjustment Safety Chuck

68500.00 INR/Piece

Product Details:

- Product Type Adjustment Safety Chuck

- General Use Holding and driving reels in winding or unwinding applications

- Material High-grade alloy steel

- Type Flange Mounted / Foot Mounted

- Capacity Up to 3000 kg

- Weight (kg) Approx. 25-70 kg (varies with model)

- Computerized No

- Click to View more

X

Adjustment Safety Chuck Price And Quantity

- 1 Piece

- 68500.00 INR/Piece

Adjustment Safety Chuck Product Specifications

- Holding and driving reels in winding or unwinding applications

- Flange Mounted / Foot Mounted

- Depends on model; typically 250mm x 160mm x 130mm

- N/A (Mechanical operation)

- High-grade alloy steel

- 2

- Mechanical

- No

- No

- Approx. 25-70 kg (varies with model)

- Adjustable inserts for various shaft sizes; quick and safe chucking

- Up to 3000 kg

- Black and Silver

- No

- Adjustment Safety Chuck

Adjustment Safety Chuck Trade Information

- 5000 Piece Per Month

- 3 Week

Product Description

Adjustment Safety Chuck is intended to tolerate reel shifts of up to 25 mm in each direction. The sliding flange is built around a conventional safety chuck with a locking mechanism. While the machine's shaft is spinning, certain materials require alignment modifications. Chuck provides exact concentricity while producing minimal noise. Adjustment Safety Chuck provide sliding drive for smooth adjustment at high speeds. This chuck is very effective as well as economical and safe to use. This requires very low maintenance costs.

Technical specification

Packaging Type | Box |

Brand | Anar |

Model Name/Number | ART-8411 |

I Deal In | New Only |

Finishing | Excellent |

Material | Casting |

Superior Safety and Adaptability

Equipped with a spring-loaded locking mechanism, the adjustment safety chuck guarantees secure reel holding during operation. The interchangeable inserts allow users to adjust for different shaft sizes, offering flexibility for diverse industrial processes. Its powder-coated surface and robust construction provide resistance to corrosion and wear.

Engineered for Industrial Excellence

With a torque capacity of up to 1500 Nm and supporting reels up to 3000 kg, this safety chuck meets the demands of heavy-duty applications. Available in both square flange and foot mounting options, it fits seamlessly into existing setups. Its mechanical operation means no electrical connections are necessary, enhancing simplicity and reliability.

Low Maintenance, High Performance

Designed for minimal upkeep, the safety chuck requires only occasional lubrication to maintain smooth function. Its sturdy, high-grade alloy steel construction and precision engineering reduce the risk of operational downtime, keeping productivity high and operational costs low.

FAQs of Adjustment Safety Chuck:

Q: How does the spring-loaded locking system enhance the safety chucks operation?

A: The spring-loaded locking system offers a reliable mechanism to automatically secure and release the shaft, minimizing the risk of accidental disengagement and enabling quick, safe reel changes during winding or unwinding processes.Q: What is the process for changing inserts to accommodate different shaft sizes?

A: The safety chuck uses interchangeable inserts that can be easily removed and replaced. Simply disengage the spring lock, pull out the existing insert, and fit in the appropriate-sized insert for your new shaft to ensure a secure hold.Q: When is periodic maintenance required and what does it involve?

A: Periodic maintenance consists mainly of lubrication at specified intervals, depending on frequency of use. This helps sustain smooth mechanical operation and extends the lifespan of the chuck; no complex servicing is needed.Q: Where can this safety chuck be installed?

A: This model is designed for mounting via square flange or foot installation, making it adaptable for both new and retrofitting in machinery used in textile, paper, printing, and packaging industries.Q: What are the main benefits of using interchangeable inserts in the safety chuck?

A: Interchangeable inserts increase operational versatility by allowing one chuck to handle a range of shaft diameters, reducing the need for multiple chucks and streamlining inventory and changeover times.Q: How does powder-coating contribute to the products durability?

A: The powder-coated finish provides a protective layer that resists rust and corrosion, making the safety chuck suitable for demanding industrial environments and enhancing its longevity.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email