- Home Page

- Company Profile

-

Our Products

- Rubber Rollers

- Textile Printing Rubber Roller

- Cork Rollers

- Film Plant Roller

- Carbon Fiber Roller

- Film Plant Rubber Rolls

- Rubber Groove Spreader Roller

- Etching Roller

- Lamination Roller

- Godded Roller

- Rubber Grooved Spreader Rollers

- Rotogravure Printing Rubber Rollers

- Polyurethane Rubber Roller

- Rubber Coated Rollers

- Quick Change Sleeve Roller

- Rotogravure Printing Roller

- Rubber Roller For Foil

- Lamination Rubber Rollers

- Rubber Spreader Roller

- Rubber Roller for Leather

- Flexo Gravure Printing Rollers

- Industrial Rubber Roller

- Flexographic Rubber Roller

- Rubber Roller

- PU Rubber Roller

- Damping Rubber Roller

- Sucker Muller Rubber Roller

- Impression Rubber Roller

- Solvent Based Lamination Rubber Roller

- Ebonite Rubber Rollers

- Adhesive Coating Rubber Roller

- Intermediate Rubber Roller

- Hollow Rubber Roller

- VMCH Coating Rubber Roller

- Nitrile Rubber Rollers

- Printing Rubber Roller

- Rubber Roller for Tyre-tube

- Hypalon Rubber Rollers

- Tap Line Rubber Roller

- Chemical Resistance Rubber Roller

- EPDM Rubber Rollers

- BOPP Film Plant Rubber Roller

- Jockey Rubber Roller

- Raffia Machine Rubber Rollers

- Solventless Lamination Rubber Roller

- Packaging Rubber Roller

- Industrial Silicone Rubber Roller

- Adhesive Applicator Silicone Rubber Roller

- Hot Stamping Silicone Rubber Roller

- Printing Rubber Rollers

- Rubber Roller PTFE Coated

- Rubber Roller Ptfe Coated

- Flexo Gravure Printing Rubber Roller

- Synthetic Rubber Roller

- Air Shafts

- Carbon Fiber Air Shaft

- Air Shaft

- Quick Lock Shaft

- Core Shaft

- Air Expanding Shafts

- Leaf Type Air Expandable Shaft

- Lug Type Air Expandable Shaft

- Multi Bladder Shaft

- Multi Tube Air Shaft

- Multi Tube Shaft

- Ball Type Quick Lock Shafts

- Metalizer Air Shaft

- Core Air Shaft

- Cantilever Air Shaft

- Industrial Air Shaft

- Mechanical Air Expandable Shaft

- Rubber Expander Roller

- Aluminium or Wooden Slat Expanders

- Rubber Load Roller

- Polyband Expander Roller

- Rubber Expander Roller for Textile Industry

- Textile Rubber Expander Roller

- Curve Bar Expander Roller

- Rubber Expander Roller for Paper Industry

- Rubber Expander Roller

- Liquid Ammonia Expander Roller

- Pop Reel Rubber Expander Roller

- Industrial Textile Expanders

- Liquid Ammonia Rubber Expander Roller

- Rubber Expander Roller For Packaging Industry

- Curved Bar Rubber Expander Roller

- Variable bow roller

- Bow Rollers

- PU Roller

- Safety Chucks

- Embossing Roller

- PTFE Coated Roller

- PTFE Sleeve Coated Roller for Paper Industries

- Rubber Expander Roller with FEP PTFE Sleeve

- Rubber Expander With FEP PTFE Sleeve

- PTFE Expander Roller

- PTFE Coated Rubber Expander

- PTFE Sleeve Expander Roller

- PTFE Sleeve Coated Roller

- PTFE Sleeve Coated Roller For Paper Industries

- PTFE Sleeve Coated Bow Roller

- Air Expanding Shaft

- Hard Chrome Plated Roller

- Steel Rollers

- Banana Roller

- Core Holding Devices

- Air Chuck

- Differential Shafts

- Nip Rollers

- Anilox Roller

- Lock Shafts

- Aluminium Guide Rollers

- Lamination Rubber Roller

- Silicone Rubber Roller

- Rubber Sleeves

- Industrial Rollers

- Industrial Shafts

- Rubber Rollers

-

Applications

- Rubber Roller for Leather Industries

- Rubber Roller for Plastic Industries

- Rubber Roller for Textile Industries

- Rubber Roller for Paper Industries

- Rubber Roller for Metal Industries

- Quality

- Rubber Roller for Packaging Industries

- Rubber Roller for Tyre-tube

- Rubber Roller for Wallpaper Industries

- Infrastructure & Facilities

- Exports

- Infrastructure & Facilities

- Exports

- Contact Us

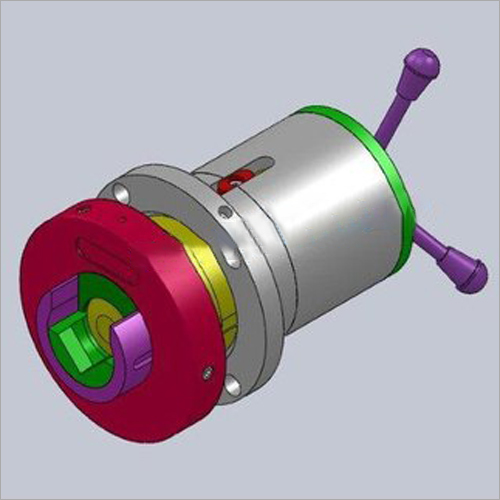

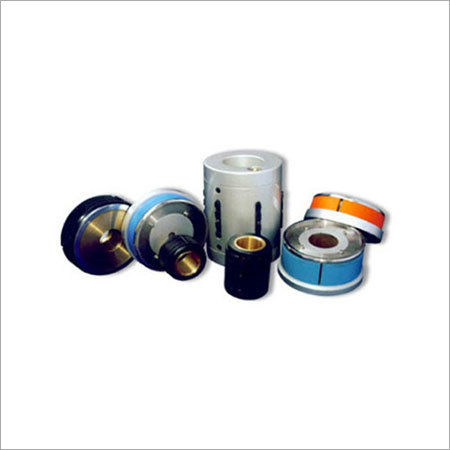

C Style Safety Chuck

25000.00 INR/Piece

Product Details:

- Product Type C Style Safety Chuck

- General Use Web Guiding, Winding, and Unwinding Applications

- Material Other

- Type Flange (Foot Mount) or Pillow Block (Pedestal Mount)

- Capacity Up to 3000 kg

- Weight (kg) Varies as per model

- Computerized No

- Click to View more

X

C Style Safety Chuck Price And Quantity

- 25000.00 INR/Piece

- 1 , , Piece

C Style Safety Chuck Product Specifications

- Up to 3000 kg

- No

- Varies as per model

- Flange (Foot Mount) or Pillow Block (Pedestal Mount)

- Manual

- Web Guiding, Winding, and Unwinding Applications

- Safety Lock Mechanism, Replaceable Insert, Rigid Build

- No

- C Style Safety Chuck

- Custom / As per specification

- No

- Silver / Grey

- 2

- Other

C Style Safety Chuck Trade Information

- Mundra

- 500 , , Piece Per Month

- 21 Days

- Standard

Product Description

Technical specification

Minimum Order Quantity | 1 Piece |

Brand | Anar |

Material | C.I |

Condition | New |

Color | Black, Silver |

Mounting | Foot,Wall |

Quantity Per Pack | 1 |

Shape | Round |

Material | S.S. 316 |

Versatile Mounting Methods

This C Style Safety Chuck offers both foot (flange) mount and pedestal mounting options, making it adaptable for various machinery layouts. These installation choices provide flexibility for integration into new or existing winding and unwinding equipment while ensuring a rigid and secure base for continuous operations.

Interchangeable and Customizable Inserts

Equipped with hardened steel inserts, the safety chuck allows for easy replacement and customization according to application needs. This feature not only extends the products lifespan but also enables compatibility with a wide range of shaft diameters, optimizing workflow efficiency.

Robust Construction and Safety Features

Built with a safety lock mechanism and rigid materials, the C Style Safety Chuck is engineered for demanding industrial use, supporting up to 3000 kg loads and speeds up to 1500 RPM (dependant on model). The powder-coated or chrome-plated finish enhances resistance to abrasion, contributing to reliable, long-term service.

FAQs of C Style Safety Chuck:

Q: How is the C Style Safety Chuck installed on machinery?

A: The C Style Safety Chuck can be installed using foot (flange) or pedestal mounting methods, allowing for flexible integration with slitter rewinders, unwinding, or winding stands, and can be customized to fit specific dimensions or machinery layouts.Q: What sizes and shaft diameters are supported by this safety chuck?

A: This safety chuck comes in various bore diameters and is suitable for standard shaft sizes ranging from 1 inch to 6 inches, ensuring compatibility with most industrial setups.Q: When should the insert of the safety chuck be replaced?

A: The insert should be replaced when noticeable wear or decreased performance is observed. Thanks to the easily replaceable design, users can swap inserts quickly to maintain operational efficiency and prolong the chucks service life.Q: What is the process for manually operating the safety chuck?

A: Operation involves manually inserting the shaft into the chuck and engaging the safety lock mechanism to secure it in place. To release, simply unlock and extract the shaft as needed, ensuring safety and ease in handling.Q: Where is the C Style Safety Chuck commonly used?

A: It is widely used in slitter rewinders, web guiding systems, as well as winding and unwinding stands in industries dealing with rolls of paper, film, textile, or foil.Q: What are the benefits of interchangeable inserts and manual operation?

A: Interchangeable inserts allow for compatibility with different shaft sizes and easy servicing, while manual operation ensures straightforward handling without the need for automated or PLC controls, enhancing operational simplicity and reducing maintenance costs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email