- Home Page

- Company Profile

-

Our Products

- Rubber Rollers

- Lamination Roller

- Film Plant Roller

- Textile Printing Rubber Roller

- Cork Rollers

- Etching Roller

- Carbon Fiber Roller

- Rubber Groove Spreader Roller

- Film Plant Rubber Rolls

- Godded Roller

- Rubber Coated Rollers

- Polyurethane Rubber Roller

- Quick Change Sleeve Roller

- Rotogravure Printing Rubber Rollers

- Rubber Grooved Spreader Rollers

- Rotogravure Printing Roller

- Rubber Roller For Foil

- Lamination Rubber Rollers

- Rubber Spreader Roller

- Rubber Roller for Leather

- Flexo Gravure Printing Rollers

- Industrial Rubber Roller

- Rubber Roller

- Flexographic Rubber Roller

- Damping Rubber Roller

- PU Rubber Roller

- Sucker Muller Rubber Roller

- Impression Rubber Roller

- Solvent Based Lamination Rubber Roller

- Ebonite Rubber Rollers

- Adhesive Coating Rubber Roller

- Intermediate Rubber Roller

- Hollow Rubber Roller

- VMCH Coating Rubber Roller

- Nitrile Rubber Rollers

- Printing Rubber Roller

- Rubber Roller for Tyre-tube

- Hypalon Rubber Rollers

- Tap Line Rubber Roller

- Chemical Resistance Rubber Roller

- EPDM Rubber Rollers

- BOPP Film Plant Rubber Roller

- Jockey Rubber Roller

- Raffia Machine Rubber Rollers

- Solventless Lamination Rubber Roller

- Packaging Rubber Roller

- Industrial Silicone Rubber Roller

- Adhesive Applicator Silicone Rubber Roller

- Hot Stamping Silicone Rubber Roller

- Printing Rubber Rollers

- Rubber Roller PTFE Coated

- Rubber Roller Ptfe Coated

- Flexo Gravure Printing Rubber Roller

- Synthetic Rubber Roller

- Air Shafts

- Air Shaft

- Carbon Fiber Air Shaft

- Quick Lock Shaft

- Core Shaft

- Air Expanding Shafts

- Leaf Type Air Expandable Shaft

- Lug Type Air Expandable Shaft

- Multi Bladder Shaft

- Multi Tube Air Shaft

- Multi Tube Shaft

- Ball Type Quick Lock Shafts

- Metalizer Air Shaft

- Core Air Shaft

- Cantilever Air Shaft

- Industrial Air Shaft

- Mechanical Air Expandable Shaft

- Rubber Expander Roller

- Aluminium or Wooden Slat Expanders

- Rubber Load Roller

- Polyband Expander Roller

- Rubber Expander Roller for Textile Industry

- Textile Rubber Expander Roller

- Curve Bar Expander Roller

- Rubber Expander Roller for Paper Industry

- Liquid Ammonia Expander Roller

- Rubber Expander Roller

- Industrial Textile Expanders

- Pop Reel Rubber Expander Roller

- Liquid Ammonia Rubber Expander Roller

- Rubber Expander Roller For Packaging Industry

- Curved Bar Rubber Expander Roller

- Variable bow roller

- Bow Rollers

- PU Roller

- Safety Chucks

- Embossing Roller

- PTFE Coated Roller

- PTFE Sleeve Coated Roller for Paper Industries

- Rubber Expander Roller with FEP PTFE Sleeve

- Rubber Expander With FEP PTFE Sleeve

- PTFE Expander Roller

- PTFE Coated Rubber Expander

- PTFE Sleeve Expander Roller

- PTFE Sleeve Coated Roller

- PTFE Sleeve Coated Roller For Paper Industries

- PTFE Sleeve Coated Bow Roller

- Air Expanding Shaft

- Hard Chrome Plated Roller

- Steel Rollers

- Banana Roller

- Core Holding Devices

- Air Chuck

- Differential Shafts

- Nip Rollers

- Anilox Roller

- Lock Shafts

- Aluminium Guide Rollers

- Lamination Rubber Roller

- Silicone Rubber Roller

- Rubber Sleeves

- Industrial Rollers

- Industrial Shafts

- Rubber Rollers

-

Applications

- Rubber Roller for Leather Industries

- Rubber Roller for Plastic Industries

- Rubber Roller for Textile Industries

- Rubber Roller for Paper Industries

- Rubber Roller for Metal Industries

- Quality

- Rubber Roller for Packaging Industries

- Rubber Roller for Tyre-tube

- Rubber Roller for Wallpaper Industries

- Infrastructure & Facilities

- Exports

- Infrastructure & Facilities

- Exports

- Contact Us

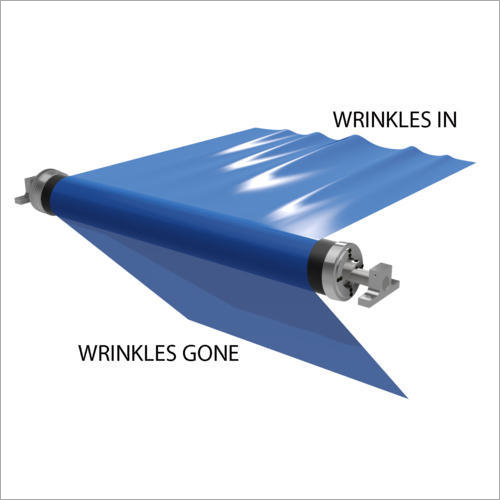

Bowed Spreader Rolls

22500.00 INR/Piece

Product Details:

- Capacity Custom, as per requirement

- Diameter 90 mm to 250 mm

- Material Stainless Steel, Rubber Coated, Aluminum

- Dimensions Customizable Length and Diameter

- Technique Precision Engineered

- Standard Industrial

- Belt Width Up to 3000 mm

- Click to View more

X

Bowed Spreader Rolls Price And Quantity

- 22500.00 INR/Piece

- 1 Piece

Bowed Spreader Rolls Product Specifications

- 90 mm to 250 mm

- Custom, as per requirement

- Highly Durable, Corrosion Resistant, Smooth Rotation, Easy Installation

- Stainless Steel, Rubber Coated, Aluminum

- Up to 3000 mm

- Customizable Length and Diameter

- Industrial

- Precision Engineered

Bowed Spreader Rolls Trade Information

- 5000 Piece Per Month

- 3 Week

Product Description

Technical specification

Application | Industrial |

Brand | Anar |

Usage/Application | Textile Industries,Paper Industries and Film Plant |

Color | Black ,Blue |

Diameter | Shaft diameter 35 to 60 mm |

Size | Customize |

Packaging Type | Standard |

Roller Diameter | 75 mm or Above |

Roller Length | Customize |

Exceptional Web Handling Solutions

Our bowed spreader rolls ensure flawless web guiding, effective spreading, and wrinkle removal for a variety of substrates, including textile, paper, plastic, and printed materials. Precision-engineered with a dynamic balancing process, these rolls provide vibration-free operation and superior performance across a wide range of working speeds and temperatures. Their high durability and advanced coatings make them an ideal choice for continuous industrial applications.

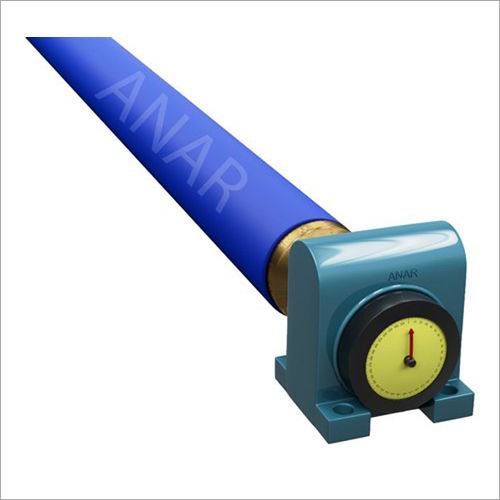

Customizable for Your Industrial Needs

With options in surface finish, length, diameter, coatings, and end fittings, these bowed spreader rolls can be tailored to specific machine setups and production requirements. The rolls can accommodate belt widths up to 3000 mm and are available with foot or flange mounting. Their stainless steel, aluminum, or rubber-coated construction ensures compatibility with various environments and processes.

FAQs of Bowed Spreader Rolls:

Q: How is the bow angle of Bowed Spreader Rolls adjusted?

A: The bow angle of these rolls can be manually adjusted for precise spreading requirements or supplied in a fixed position, enhancing control over web alignment and wrinkle removal.Q: What is the maximum operating speed and belt width supported by these spreader rolls?

A: Bowed spreader rolls are designed to operate efficiently at speeds up to 600 m/min and can handle belt widths of up to 3000 mm, making them suitable for large-scale industrial production lines.Q: When should I choose a mirror finish versus a matt finish for the roller surface?

A: A mirror finish is recommended when minimal surface friction and smooth rotation are paramount, while a matt finish suits applications requiring enhanced grip or specific visual profiles for material processing.Q: Where can these spreader rolls be installed, and what mounting types are available?

A: These rolls offer versatile installation options, including foot mounted and flange mounted setups, accommodating diverse machine designs in textile, paper, plastic, and printing industries.Q: What coating materials are available, and how do they affect performance?

A: Coating choices include Natural Rubber, Silicone, EPDM, and Polyurethane. Each material offers distinct advantagessuch as chemical resistance, temperature stability, or superior gripto optimize roll performance according to application needs.Q: How does dynamic balancing benefit the operation of Bowed Spreader Rolls?

A: Dynamic balancing ensures smooth, vibration-free rotation at high speeds, reducing wear, enhancing product longevity, and contributing to consistent, high-quality processing outcomes.Q: What are the main benefits of using Bowed Spreader Rolls in industrial applications?

A: Key benefits include reliable web guiding, efficient wrinkle removal, customizable dimensions, easy installation, corrosion resistance, and low maintenance design, helping boost production efficiency and product quality.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email