- Home Page

- Company Profile

-

Our Products

- Rubber Rollers

- Textile Printing Rubber Roller

- Cork Rollers

- Film Plant Roller

- Carbon Fiber Roller

- Film Plant Rubber Rolls

- Rubber Groove Spreader Roller

- Etching Roller

- Lamination Roller

- Godded Roller

- Rubber Grooved Spreader Rollers

- Rotogravure Printing Rubber Rollers

- Polyurethane Rubber Roller

- Rubber Coated Rollers

- Quick Change Sleeve Roller

- Rotogravure Printing Roller

- Rubber Roller For Foil

- Lamination Rubber Rollers

- Rubber Spreader Roller

- Rubber Roller for Leather

- Flexo Gravure Printing Rollers

- Industrial Rubber Roller

- Flexographic Rubber Roller

- Rubber Roller

- PU Rubber Roller

- Damping Rubber Roller

- Sucker Muller Rubber Roller

- Impression Rubber Roller

- Solvent Based Lamination Rubber Roller

- Ebonite Rubber Rollers

- Adhesive Coating Rubber Roller

- Intermediate Rubber Roller

- Hollow Rubber Roller

- VMCH Coating Rubber Roller

- Nitrile Rubber Rollers

- Printing Rubber Roller

- Rubber Roller for Tyre-tube

- Hypalon Rubber Rollers

- Tap Line Rubber Roller

- Chemical Resistance Rubber Roller

- EPDM Rubber Rollers

- BOPP Film Plant Rubber Roller

- Jockey Rubber Roller

- Raffia Machine Rubber Rollers

- Solventless Lamination Rubber Roller

- Packaging Rubber Roller

- Industrial Silicone Rubber Roller

- Adhesive Applicator Silicone Rubber Roller

- Hot Stamping Silicone Rubber Roller

- Printing Rubber Rollers

- Rubber Roller PTFE Coated

- Rubber Roller Ptfe Coated

- Flexo Gravure Printing Rubber Roller

- Synthetic Rubber Roller

- Air Shafts

- Carbon Fiber Air Shaft

- Air Shaft

- Quick Lock Shaft

- Core Shaft

- Air Expanding Shafts

- Leaf Type Air Expandable Shaft

- Lug Type Air Expandable Shaft

- Multi Bladder Shaft

- Multi Tube Air Shaft

- Multi Tube Shaft

- Ball Type Quick Lock Shafts

- Metalizer Air Shaft

- Core Air Shaft

- Cantilever Air Shaft

- Industrial Air Shaft

- Mechanical Air Expandable Shaft

- Rubber Expander Roller

- Aluminium or Wooden Slat Expanders

- Rubber Load Roller

- Polyband Expander Roller

- Rubber Expander Roller for Textile Industry

- Textile Rubber Expander Roller

- Curve Bar Expander Roller

- Rubber Expander Roller for Paper Industry

- Rubber Expander Roller

- Liquid Ammonia Expander Roller

- Pop Reel Rubber Expander Roller

- Industrial Textile Expanders

- Liquid Ammonia Rubber Expander Roller

- Rubber Expander Roller For Packaging Industry

- Curved Bar Rubber Expander Roller

- Variable bow roller

- Bow Rollers

- PU Roller

- Safety Chucks

- Embossing Roller

- PTFE Coated Roller

- PTFE Sleeve Coated Roller for Paper Industries

- Rubber Expander Roller with FEP PTFE Sleeve

- Rubber Expander With FEP PTFE Sleeve

- PTFE Expander Roller

- PTFE Coated Rubber Expander

- PTFE Sleeve Expander Roller

- PTFE Sleeve Coated Roller

- PTFE Sleeve Coated Roller For Paper Industries

- PTFE Sleeve Coated Bow Roller

- Air Expanding Shaft

- Hard Chrome Plated Roller

- Steel Rollers

- Banana Roller

- Core Holding Devices

- Air Chuck

- Differential Shafts

- Nip Rollers

- Anilox Roller

- Lock Shafts

- Aluminium Guide Rollers

- Lamination Rubber Roller

- Silicone Rubber Roller

- Rubber Sleeves

- Industrial Rollers

- Industrial Shafts

- Rubber Rollers

-

Applications

- Rubber Roller for Leather Industries

- Rubber Roller for Plastic Industries

- Rubber Roller for Textile Industries

- Rubber Roller for Paper Industries

- Rubber Roller for Metal Industries

- Quality

- Rubber Roller for Packaging Industries

- Rubber Roller for Tyre-tube

- Rubber Roller for Wallpaper Industries

- Infrastructure & Facilities

- Exports

- Infrastructure & Facilities

- Exports

- Contact Us

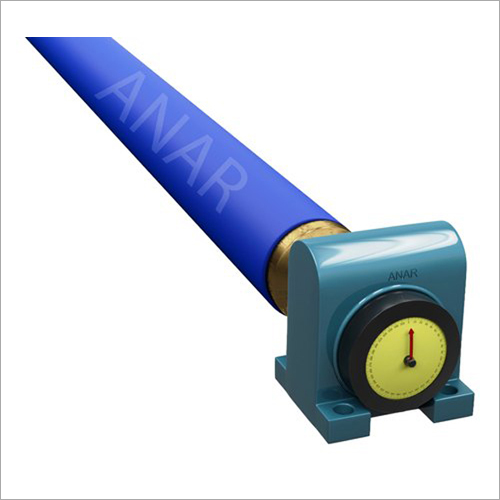

Bowed Spreader Roll

10000.00 INR/Piece

Product Details:

- Capacity Up to 1000 kg

- Diameter 76 mm to 300 mm

- Material Stainless Steel, Aluminum, Rubber Sleeve

- Dimensions Length: 500 mm to 8000 mm

- Technique Precision Balancing, Dynamic Balancing

- Standard Customizable as per requirements

- Belt Width Up to 4000 mm

- Click to View more

X

Bowed Spreader Roll Price And Quantity

- 10000.00 INR/Piece

- 1 Piece

Bowed Spreader Roll Product Specifications

- Length: 500 mm to 8000 mm

- Stainless Steel, Aluminum, Rubber Sleeve

- Wrinkle removing, Web handling, High speed performance

- Up to 1000 kg

- Up to 4000 mm

- Customizable as per requirements

- 76 mm to 300 mm

- Precision Balancing, Dynamic Balancing

Bowed Spreader Roll Trade Information

- 2000 Piece Per Month

- 25 Days

Product Description

Technical specification

Packaging Type | Standard |

Brand | Anar |

Usage/Application | Paper Industries, Textile Industries , Film Plant |

Color | Blue, Black |

Temperature | 40 C to 120 C |

Packing Type | Standard |

Superior Web Handling and Wrinkle Removal

These Bowed Spreader Rolls are designed to ensure effective web handling and eliminate wrinkles even at high speeds. Their balanced construction, available in polished or rubber-covered surfaces, allows for smooth operation in textile, film, printing, and packaging industries, enhancing product quality and efficiency.

Customizable Configuration to Suit Every Need

Whether you require specific end fittings, cover hardness between 20-100 Shore A, or specialized dimensions, these rolls offer a flexible solution. Motorized or free-rotating drive options are available, ensuring seamless integration into existing or new systems, with tailored solutions to meet any requirement.

Reliable, Durable, and Easy to Maintain

Constructed from premium materials like stainless steel, aluminum, and rubber sleeves, our spreader rolls offer long life and excellent corrosion resistance. Precision and dynamic balancing, combined with low-maintenance features, guarantee uninterrupted performance and easy installation or replacement.

FAQs of Bowed Spreader Roll:

Q: How does the bow angle adjustment improve performance in web handling applications?

A: The bow angle on these spreader rolls can be manually or pneumatically adjusted, allowing users to precisely control the degree of web spreading for wrinkle removal and optimal tension. This flexibility ensures superior performance for various materials and applications.Q: What industries can use this Bowed Spreader Roll effectively?

A: These spreader rolls are ideal for textile, paper, film, packaging, and printing industries. Their design and robust construction enable consistent performance in applications where web wrinkle removal and high-speed operation are essential.Q: When should I select a rubber-covered surface versus a polished surface for my application?

A: A rubber-covered surface is preferable for delicate or sensitive webs, as it provides gentle contact and improved traction. Polished surfaces are recommended for less sensitive applications where cleanliness and easy maintenance are priorities.Q: Where can these Bowed Spreader Rolls be installed within a production line?

A: They are typically installed after web winding/unwinding stations, drying sections, or before slitting and rewinding unitswherever wrinkle removal and web spreading are required for stable downstream processing.Q: What is the process for installing and replacing the Bowed Spreader Roll?

A: Installation and replacement are quick and straightforward due to the rolls easy-to-install design and customizable end fittings (flanged, shaft, or as specified). Typically, minimal tooling and downtime are required, streamlining maintenance schedules.Q: How does the rolls construction contribute to its long-term durability and performance?

A: Constructed from stainless steel, aluminum, and high-quality rubber sleeves, these spreader rolls feature heavy-duty, long-life bearings and excellent corrosion resistance. They are dynamically and precisely balanced, ensuring stable, high-speed operation and reduced wear.Q: What are the main benefits of choosing this Bowed Spreader Roll for my process?

A: The primary advantages include effective wrinkle removal, high-speed compatibility (up to 3000 RPM), exceptional corrosion resistance, customizable configurations, easy installation and maintenance, and reliable performance with various web materials and widths.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email