- Home Page

- Company Profile

-

Our Products

- Rubber Rollers

- Textile Printing Rubber Roller

- Cork Rollers

- Film Plant Roller

- Carbon Fiber Roller

- Film Plant Rubber Rolls

- Rubber Groove Spreader Roller

- Etching Roller

- Lamination Roller

- Godded Roller

- Rubber Grooved Spreader Rollers

- Rotogravure Printing Rubber Rollers

- Polyurethane Rubber Roller

- Rubber Coated Rollers

- Quick Change Sleeve Roller

- Rotogravure Printing Roller

- Rubber Roller For Foil

- Lamination Rubber Rollers

- Rubber Spreader Roller

- Rubber Roller for Leather

- Flexo Gravure Printing Rollers

- Industrial Rubber Roller

- Flexographic Rubber Roller

- Rubber Roller

- PU Rubber Roller

- Damping Rubber Roller

- Sucker Muller Rubber Roller

- Impression Rubber Roller

- Solvent Based Lamination Rubber Roller

- Ebonite Rubber Rollers

- Adhesive Coating Rubber Roller

- Intermediate Rubber Roller

- Hollow Rubber Roller

- VMCH Coating Rubber Roller

- Nitrile Rubber Rollers

- Printing Rubber Roller

- Rubber Roller for Tyre-tube

- Hypalon Rubber Rollers

- Tap Line Rubber Roller

- Chemical Resistance Rubber Roller

- EPDM Rubber Rollers

- BOPP Film Plant Rubber Roller

- Jockey Rubber Roller

- Raffia Machine Rubber Rollers

- Solventless Lamination Rubber Roller

- Packaging Rubber Roller

- Industrial Silicone Rubber Roller

- Adhesive Applicator Silicone Rubber Roller

- Hot Stamping Silicone Rubber Roller

- Printing Rubber Rollers

- Rubber Roller PTFE Coated

- Rubber Roller Ptfe Coated

- Flexo Gravure Printing Rubber Roller

- Synthetic Rubber Roller

- Air Shafts

- Carbon Fiber Air Shaft

- Air Shaft

- Quick Lock Shaft

- Core Shaft

- Air Expanding Shafts

- Leaf Type Air Expandable Shaft

- Lug Type Air Expandable Shaft

- Multi Bladder Shaft

- Multi Tube Air Shaft

- Multi Tube Shaft

- Ball Type Quick Lock Shafts

- Metalizer Air Shaft

- Core Air Shaft

- Cantilever Air Shaft

- Industrial Air Shaft

- Mechanical Air Expandable Shaft

- Rubber Expander Roller

- Aluminium or Wooden Slat Expanders

- Rubber Load Roller

- Polyband Expander Roller

- Rubber Expander Roller for Textile Industry

- Textile Rubber Expander Roller

- Curve Bar Expander Roller

- Rubber Expander Roller for Paper Industry

- Rubber Expander Roller

- Liquid Ammonia Expander Roller

- Pop Reel Rubber Expander Roller

- Industrial Textile Expanders

- Liquid Ammonia Rubber Expander Roller

- Rubber Expander Roller For Packaging Industry

- Curved Bar Rubber Expander Roller

- Variable bow roller

- Bow Rollers

- PU Roller

- Safety Chucks

- Embossing Roller

- PTFE Coated Roller

- PTFE Sleeve Coated Roller for Paper Industries

- Rubber Expander Roller with FEP PTFE Sleeve

- Rubber Expander With FEP PTFE Sleeve

- PTFE Expander Roller

- PTFE Coated Rubber Expander

- PTFE Sleeve Expander Roller

- PTFE Sleeve Coated Roller

- PTFE Sleeve Coated Roller For Paper Industries

- PTFE Sleeve Coated Bow Roller

- Air Expanding Shaft

- Hard Chrome Plated Roller

- Steel Rollers

- Banana Roller

- Core Holding Devices

- Air Chuck

- Differential Shafts

- Nip Rollers

- Anilox Roller

- Lock Shafts

- Aluminium Guide Rollers

- Lamination Rubber Roller

- Silicone Rubber Roller

- Rubber Sleeves

- Industrial Rollers

- Industrial Shafts

- Rubber Rollers

-

Applications

- Rubber Roller for Leather Industries

- Rubber Roller for Plastic Industries

- Rubber Roller for Textile Industries

- Rubber Roller for Paper Industries

- Rubber Roller for Metal Industries

- Quality

- Rubber Roller for Packaging Industries

- Rubber Roller for Tyre-tube

- Rubber Roller for Wallpaper Industries

- Infrastructure & Facilities

- Exports

- Infrastructure & Facilities

- Exports

- Contact Us

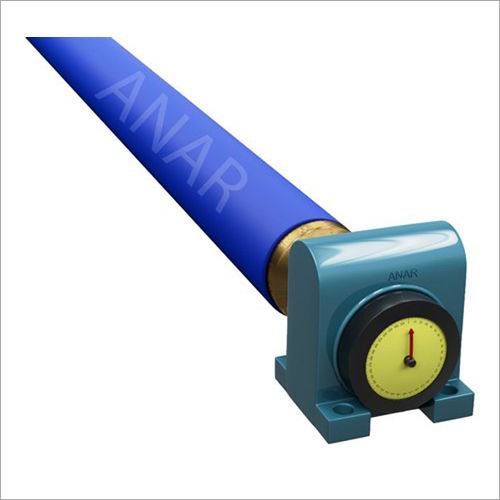

Variable Bow Rollers

10000.00 INR/Piece

Product Details:

- Diameter 150 - 280 mm

- Capacity Heavy-duty application

- Material Stainless Steel / Mild Steel / Aluminum

- Dimensions Customizable as per requirement

- Technique Dynamically balanced, CNC machined

- Standard ISO 9001:2015 certified

- Belt Width Up to 2400 mm

- Click to View more

X

Variable Bow Rollers Price And Quantity

- 1 Piece

- 10000.00 INR/Piece

Variable Bow Rollers Product Specifications

- Dynamically balanced, CNC machined

- Adjustable bow profile, Precision engineered

- ISO 9001:2015 certified

- Heavy-duty application

- Up to 2400 mm

- Stainless Steel / Mild Steel / Aluminum

- Customizable as per requirement

- 150 - 280 mm

Variable Bow Rollers Trade Information

- 2000 Piece Per Month

- 25 Days

Product Description

Technical specification

Application | Industrial |

Brand | Anar |

Material | Aluminum |

Shaft Diameter | Custom |

Size/Dimension | Custom |

Usage/Application | Textile,Paper,Plastic Industries |

Used | Textile,Paper,Plastic Industries |

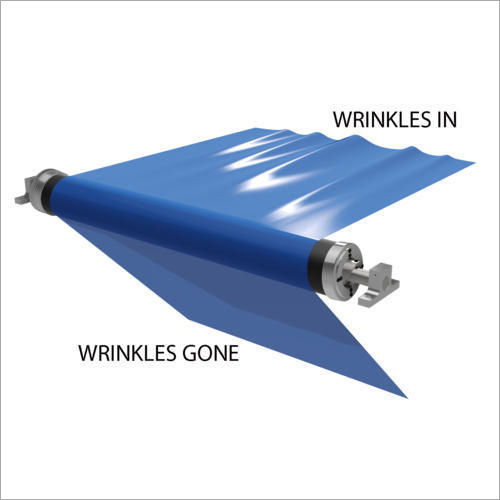

Versatile Application Across Industries

Engineered for use in textile, paper, film, and foil processing, Variable Bow Rollers effectively address web spreading and wrinkle removal challenges. Their customizable design ensures compatibility with a wide array of production lines, making them a valuable asset in industries that demand precise material handling and high-quality output.

Precision Engineering and Heavy-Duty Performance

Each roller is meticulously crafted using CNC machining and dynamic balancing techniques, which guarantees exceptional stability under heavy loads. With robust construction from stainless steel, mild steel, or aluminum, and a load-bearing, vibration-resistant design, Variable Bow Rollers are built to endure rigorous industrial environments.

Tailored Solutions for Unique Requirements

Understanding that different processes may demand unique roller specifications, these bow rollers can be fully tailored in terms of dimensions, surface finishes, and mounting types. Whether you require mirror-polished or matte finishes, or single or double shaft ends, customization options ensure a perfect fit for your operations requirements.

FAQs of Variable Bow Rollers:

Q: How do Variable Bow Rollers help remove wrinkles in web materials?

A: Variable Bow Rollers use an adjustable bow profile to apply controlled lateral movement to web materials such as textiles, paper, films, and foils. This action spreads the web and eliminates wrinkles, enhancing product quality and processing efficiency.Q: What adjustment mechanisms are available for Variable Bow Rollers?

A: These rollers can be adjusted either manually or with a pneumatic system, allowing operators to fine-tune the bow according to specific web characteristics and operational needs for optimal performance.Q: When should you consider using a Variable Bow Roller in your production line?

A: If your process involves continuous sheets (webs) prone to wrinkles or uneven stretching, especially with fabrics, films, papers, or foils, installing a Variable Bow Roller can significantly improve product uniformity and decrease material wastage.Q: Where can these rollers be installed, and what mounting options are available?

A: Variable Bow Rollers can be integrated into various positions within a processing line, utilizing flange, foot, or bespoke mounting systems depending on spatial and operational requirements. Custom mounting solutions can be provided upon request.Q: What is the process for customizing a Variable Bow Roller to meet specific application requirements?

A: Customization involves selecting dimensions, shaft configurations, surface finishes (mirror polished or matte), and materials (stainless steel, mild steel, or aluminum) based on your lines web material, operating temperature, and width requirements. Consultation with the supplier ensures the roller is engineered to exact specifications.Q: How does the design of Variable Bow Rollers benefit industrial users?

A: Their precision-balanced and robust construction provides exceptional stability, reduces vibration, extends service life, and improves output quality. Adjustable bow profile ensures maximum versatility and adaptability across various web materials and industrial processes.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email