- होम पेज

- कंपनी प्रोफाइल

-

हमारे उत्पाद

- रबर रोलर्स

- टेक्सटाइल प्रिंटिंग रबर रोलर

- कॉर्क रोलर्स

- फिल्म प्लांट रोलर

- कार्बन फाइबर रोलर

- फिल्म प्लांट रबर रोल्स

- रबर ग्रूव स्प्रेडर रोलर

- नक़्क़ाशी रोलर

- लेमिनेशन रोलर

- गॉडडेड रोलर

- रबर ग्रूव्ड स्प्रेडर रोलर्स

- रोटोग्राव्योर प्रिंटिंग रबर रोलर्स

- पॉलीयुरेथेन रबर रोलर

- रबर कोटेड रोलर्स

- क्विक चेंज स्लीव रोलर

- रोटोग्राव्योर प्रिंटिंग रोलर

- फ़ॉइल के लिए रबर रोलर

- लैमिनेशन रबर रोलर्स

- रबर स्प्रेडर रोलर

- चमड़े के लिए रबर रोलर

- फ्लेक्सो ग्रेव्योर प्रिंटिंग रोलर्स

- औद्योगिक रबर रोलर

- फ्लेक्सोग्राफिक रबर रोलर

- रबर रोलर

- पीयू रबर रोलर

- डंपिंग रबर रोलर

- सॉकर मुलर रबर रोलर

- इंप्रेशन रबर रोलर

- सॉल्वेंट आधारित लैमिनेशन रबर रोलर

- इबोनाइट रबर रोलर्स

- चिपकने वाला कोटिंग रबर रोलर

- इंटरमीडिएट रबर रोलर

- खोखला रबर रोलर

- VMCH कोटिंग रबर रोलर

- नाइट्राइल रबर रोलर्स

- प्रिंटिंग रबर रोलर

- टायर-ट्यूब के लिए रबर रोलर

- हाइपलॉन रबर रोलर्स

- टैप लाइन रबर रोलर

- रासायनिक प्रतिरोध रबर रोलर

- EPDM रबर रोलर्स

- BOPP फिल्म प्लांट रबर रोलर

- जॉकी रबर रोलर

- राफिया मशीन रबर रोलर्स

- सॉल्वेंटलेस लैमिनेशन रबर रोलर

- पैकेजिंग रबर रोलर

- औद्योगिक सिलिकॉन रबर रोलर

- चिपकने वाला ऐप्लिकेटर सिलिकॉन रबर रोलर

- हॉट स्टैम्पिंग सिलिकॉन रबर रोलर

- प्रिंटिंग रबर रोलर्स

- रबर रोलर PTFE लेपित

- रबर रोलर पीटीएफ लेपित

- फ्लेक्सो ग्रेव्योर प्रिंटिंग रबर रोलर

- सिंथेटिक रबर रोलर

- वायु शाफ्ट

- एयर शाफ्ट

- कार्बन फाइबर एयर शाफ्ट

- क्विक लॉक शाफ्ट

- कोर शाफ्ट

- एयर एक्सपैंडिंग शाफ्ट

- लीफ टाइप एयर एक्सपेंडेबल शाफ्ट

- लुग टाइप एयर एक्सपेंडेबल शाफ्ट

- मल्टी ब्लैडर शाफ्ट

- मल्टी ट्यूब एयर शाफ्ट

- मल्टी ट्यूब शाफ्ट

- बॉल टाइप क्विक लॉक शाफ्ट

- मेटलाइज़र एयर शाफ्ट

- कोर एयर शाफ्ट

- कैंटिलीवर एयर शाफ्ट

- औद्योगिक एयर शाफ्ट

- मैकेनिकल एयर एक्सपेंडेबल शाफ्ट

- रबर विस्तारक रोलर

- एल्युमिनियम या वुडन स्लेट एक्सपैंडर्स

- रबर लोड रोलर

- पॉलीबैंड एक्सपैंडर रोलर

- टेक्सटाइल उद्योग के लिए रबर एक्सपैंडर रोलर

- टेक्सटाइल रबर एक्सपैंडर रोलर

- कर्व बार एक्सपैंडर रोलर

- पेपर उद्योग के लिए रबर एक्सपैंडर रोलर

- रबर एक्सपैंडर रोलर

- तरल अमोनिया एक्सपैंडर रोलर

- पॉप रील रबर एक्सपैंडर रोलर

- औद्योगिक वस्त्र विस्तारक

- तरल अमोनिया रबर एक्सपैंडर रोलर

- पैकेजिंग उद्योग के लिए रबर एक्सपैंडर रोलर

- घुमावदार बार रबर एक्सपैंडर रोलर

- धनुष रोलर्स

- पु रोलर

- स्टील उद्योग के लिए पीयू रोलर्स

- पीवीसी प्रोफाइल प्रिंटिंग के लिए पीयू रोलर्स

- सर्कुलर लूम्स रोलर्स

- हॉट कास्ट पॉलीयूरेथेन रोलर्स

- पिंच रोलर्स

- पॉलीयुरेथेन ग्रेविटी रोलर्स

- गाइड रोलर्स

- पॉलीयुरेथेन लोड रोलर्स

- शीट मेटल इंडस्ट्री के लिए पीयू रोलर्स

- सीमेंट कोटिंग पाइप प्लांट के लिए पीयू रोलर्स

- पीयू सपोर्ट रोलर्स

- सुरक्षा चक

- एम्बॉसिंग रोलर

- पीटीएफई लेपित रोलर

- वायु विस्तार दस्ता

- हार्ड क्रोम प्लेटेड रोलर

- स्टील रोलर्स

- केले का रोलर

- कोर होल्डिंग डिवाइस

- एयर चक

- विभेदक शाफ्ट

- निप रोलर्स

- अनिलॉक्स रोलर

- लॉक शाफ्ट

- एल्यूमिनियम गाइड रोलर्स

- लेमिनेशन रबर रोलर

- सिलिकॉन रबर रोलर

- रबर की आस्तीनें

- औद्योगिक रोलर्स

- औद्योगिक शाफ्ट

- रबर रोलर्स

-

Applications

- लेदर इंडस्ट्रीज के लिए रबर रोलर

- प्लास्टिक उद्योग के लिए रबर रोलर

- Rubber Roller for Textile Industries

- Rubber Roller for Paper Industries

- मेटल इंडस्ट्रीज के लिए रबर रोलर

- Quality

- Rubber Roller for Packaging Industries

- Rubber Roller for Tyre-tube

- Rubber Roller for Wallpaper Industries

- Infrastructure & Facilities

- Exports

- Infrastructure & Facilities

- Exports

- संपर्क करें

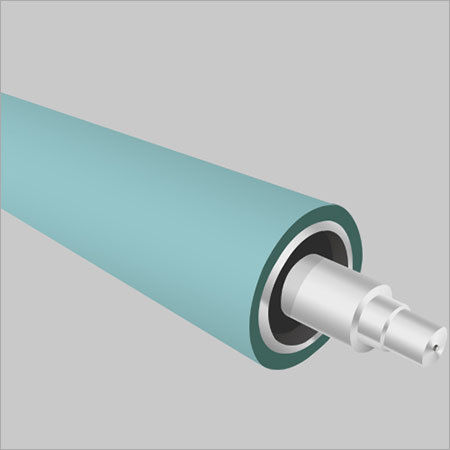

पेपर लैमिनेशन रोलर

13000.00 आईएनआर/टुकड़ा

उत्पाद विवरण:

- शर्त

- स्ट्रक्चर Cylindrical Roller with Metal Core

- रबर का प्रकार High-Quality Synthetic Rubber

- सामग्री को संभालें

- हैंडल कलर Blue

- पाइल की लंबाई Standard (Customizable on request)

- वज़न Approx. 2.5 kg

- अधिक देखने के लिए क्लिक करें

X

पेपर लैमिनेशन रोलर मूल्य और मात्रा

- टुकड़ा/टुकड़े

- टुकड़ा/टुकड़े

- 1

पेपर लैमिनेशन रोलर उत्पाद की विशेषताएं

- Blue

- Cylindrical Roller with Metal Core

- Approx. 2.5 kg

- Standard (Customizable on request)

- High-Quality Synthetic Rubber

पेपर लैमिनेशन रोलर व्यापार सूचना

- 850 प्रति महीने

- 21 दिन

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email