- Home Page

- Company Profile

-

Our Products

- Rubber Rollers

- Lamination Roller

- Film Plant Roller

- Textile Printing Rubber Roller

- Cork Rollers

- Etching Roller

- Carbon Fiber Roller

- Rubber Groove Spreader Roller

- Film Plant Rubber Rolls

- Godded Roller

- Rubber Coated Rollers

- Polyurethane Rubber Roller

- Quick Change Sleeve Roller

- Rotogravure Printing Rubber Rollers

- Rubber Grooved Spreader Rollers

- Rotogravure Printing Roller

- Rubber Roller For Foil

- Lamination Rubber Rollers

- Rubber Spreader Roller

- Rubber Roller for Leather

- Flexo Gravure Printing Rollers

- Industrial Rubber Roller

- Rubber Roller

- Flexographic Rubber Roller

- Damping Rubber Roller

- PU Rubber Roller

- Sucker Muller Rubber Roller

- Impression Rubber Roller

- Solvent Based Lamination Rubber Roller

- Ebonite Rubber Rollers

- Adhesive Coating Rubber Roller

- Intermediate Rubber Roller

- Hollow Rubber Roller

- VMCH Coating Rubber Roller

- Nitrile Rubber Rollers

- Printing Rubber Roller

- Rubber Roller for Tyre-tube

- Hypalon Rubber Rollers

- Tap Line Rubber Roller

- Chemical Resistance Rubber Roller

- EPDM Rubber Rollers

- BOPP Film Plant Rubber Roller

- Jockey Rubber Roller

- Raffia Machine Rubber Rollers

- Solventless Lamination Rubber Roller

- Packaging Rubber Roller

- Industrial Silicone Rubber Roller

- Adhesive Applicator Silicone Rubber Roller

- Hot Stamping Silicone Rubber Roller

- Printing Rubber Rollers

- Rubber Roller PTFE Coated

- Rubber Roller Ptfe Coated

- Flexo Gravure Printing Rubber Roller

- Synthetic Rubber Roller

- Air Shafts

- Air Shaft

- Carbon Fiber Air Shaft

- Quick Lock Shaft

- Core Shaft

- Air Expanding Shafts

- Leaf Type Air Expandable Shaft

- Lug Type Air Expandable Shaft

- Multi Bladder Shaft

- Multi Tube Air Shaft

- Multi Tube Shaft

- Ball Type Quick Lock Shafts

- Metalizer Air Shaft

- Core Air Shaft

- Cantilever Air Shaft

- Industrial Air Shaft

- Mechanical Air Expandable Shaft

- Rubber Expander Roller

- Aluminium or Wooden Slat Expanders

- Rubber Load Roller

- Polyband Expander Roller

- Rubber Expander Roller for Textile Industry

- Textile Rubber Expander Roller

- Curve Bar Expander Roller

- Rubber Expander Roller for Paper Industry

- Liquid Ammonia Expander Roller

- Rubber Expander Roller

- Industrial Textile Expanders

- Pop Reel Rubber Expander Roller

- Liquid Ammonia Rubber Expander Roller

- Rubber Expander Roller For Packaging Industry

- Curved Bar Rubber Expander Roller

- Variable bow roller

- Bow Rollers

- PU Roller

- Safety Chucks

- Embossing Roller

- PTFE Coated Roller

- PTFE Sleeve Coated Roller for Paper Industries

- Rubber Expander Roller with FEP PTFE Sleeve

- Rubber Expander With FEP PTFE Sleeve

- PTFE Expander Roller

- PTFE Coated Rubber Expander

- PTFE Sleeve Expander Roller

- PTFE Sleeve Coated Roller

- PTFE Sleeve Coated Roller For Paper Industries

- PTFE Sleeve Coated Bow Roller

- Air Expanding Shaft

- Hard Chrome Plated Roller

- Steel Rollers

- Banana Roller

- Core Holding Devices

- Air Chuck

- Differential Shafts

- Nip Rollers

- Anilox Roller

- Lock Shafts

- Aluminium Guide Rollers

- Lamination Rubber Roller

- Silicone Rubber Roller

- Rubber Sleeves

- Industrial Rollers

- Industrial Shafts

- Rubber Rollers

-

Applications

- Rubber Roller for Leather Industries

- Rubber Roller for Plastic Industries

- Rubber Roller for Textile Industries

- Rubber Roller for Paper Industries

- Rubber Roller for Metal Industries

- Quality

- Rubber Roller for Packaging Industries

- Rubber Roller for Tyre-tube

- Rubber Roller for Wallpaper Industries

- Infrastructure & Facilities

- Exports

- Infrastructure & Facilities

- Exports

- Contact Us

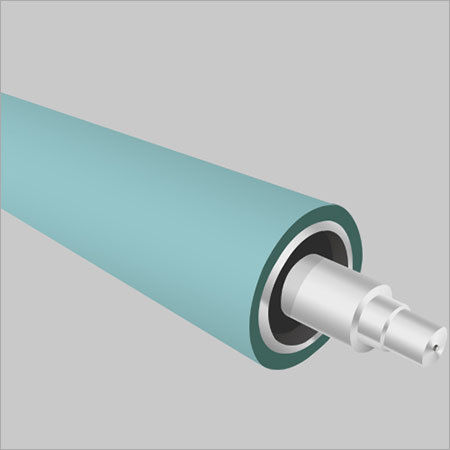

Paper Lamination Roller

13000.00 INR/Piece

Product Details:

- Structure Cylindrical Roller with Metal Core

- Condition New

- Rubber Type High-Quality Synthetic Rubber

- Handle Material Metal with Anti-Slip Grip

- Handle Color Blue

- Pile Length Standard (Customizable on request)

- Weight Approx. 2.5 kg

- Click to View more

X

Paper Lamination Roller Price And Quantity

- 1 Piece

- 13000.00 INR/Piece

Paper Lamination Roller Product Specifications

- Standard (Customizable on request)

- New

- Cylindrical Roller with Metal Core

- Heat Resistant, Wear Resistant, High Surface Finish

- Blue

- Approx. 2.5 kg

- Metal with Anti-Slip Grip

- High-Quality Synthetic Rubber

Paper Lamination Roller Trade Information

- 850 Piece Per Month

- 21 Days

Product Description

Technical specification

Material | Rubber / M.S |

Roller Diameter | Upto 500 mm |

Roller Length | Upto 6000 mm |

Roller Surface | Neoprene,Nitrile Rubber |

Design | Customize |

Finishing | Rubber |

Hardness | 60 to 70 |

Temperature | Upto 250 |

Color | Black,Blue,Red,Yellow |

Brand | Anar |

Dimension | Customize |

Precision Manufacturing for Seamless Lamination

Crafted for demanding lamination and industrial printing, our rollers utilize high-quality synthetic rubber and a sturdy mild steel core. The result is a product that withstands continuous operation and vigorous industrial use, all while promoting optimal lamination results. Individual specifications such as diameter and length can be tailored with precision, ensuring seamless integration in your workflow.

Customizable Features and Industrial Durability

Each Paper Lamination Roller is designed with customizable dimensions, core materials, and handle details to cater to diverse industrial needs. The rollers high surface hardness, smooth glazed finish, and heat resistance ensure longevity and consistent performance, making it well-suited for high-volume, repetitive tasks in challenging environments.

FAQs of Paper Lamination Roller:

Q: How is the Paper Lamination Roller installed in industrial machines?

A: The roller comes with either fixed or removable mounting options, making installation straightforward in most lamination and industrial printing machines. The metal core is engineered for secure fitting, and instructions are included for easy integration.Q: What customization options are available for this lamination roller?

A: Customers can request changes in diameter (starting from 100 mm), length (up to 1500 mm), pile length, surface finish, and even handle color. The rollers core material, surface hardness, and mounting type can also be specified based on requirements.Q: When should I replace or maintain a lamination roller?

A: Routine inspection is recommended, especially for applications with continuous operation. Replace the roller if theres evident surface wear, loss of finish, or decreased lamination quality. Regular cleaning prolongs service life and preserves high surface finish.Q: Where is this product manufactured and shipped from?

A: These rollers are manufactured in India and can be exported worldwide. Secure bubble wrap and sturdy box packaging ensure safe delivery, whether domestically or internationally.Q: What is the benefit of using a roller with 6070 Shore A hardness?

A: A surface hardness of 6070 Shore A provides an ideal balance between durability and flexibility, yielding superior lamination results without damaging paper or print media. This hardness ensures the roller resists deformation and wear, enabling consistent output.Q: How does the roller handle high operating temperatures?

A: Constructed from heat-resistant synthetic rubber, the roller operates reliably up to 120C. This makes it suitable for high-speed, intensive lamination and printing processes without compromising performance or material integrity.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email