- Home Page

- Company Profile

-

Our Products

- Rubber Rollers

- Textile Printing Rubber Roller

- Cork Rollers

- Film Plant Roller

- Carbon Fiber Roller

- Film Plant Rubber Rolls

- Rubber Groove Spreader Roller

- Etching Roller

- Lamination Roller

- Godded Roller

- Rubber Grooved Spreader Rollers

- Rotogravure Printing Rubber Rollers

- Polyurethane Rubber Roller

- Rubber Coated Rollers

- Quick Change Sleeve Roller

- Rotogravure Printing Roller

- Rubber Roller For Foil

- Lamination Rubber Rollers

- Rubber Spreader Roller

- Rubber Roller for Leather

- Flexo Gravure Printing Rollers

- Industrial Rubber Roller

- Flexographic Rubber Roller

- Rubber Roller

- PU Rubber Roller

- Damping Rubber Roller

- Sucker Muller Rubber Roller

- Impression Rubber Roller

- Solvent Based Lamination Rubber Roller

- Ebonite Rubber Rollers

- Adhesive Coating Rubber Roller

- Intermediate Rubber Roller

- Hollow Rubber Roller

- VMCH Coating Rubber Roller

- Nitrile Rubber Rollers

- Printing Rubber Roller

- Rubber Roller for Tyre-tube

- Hypalon Rubber Rollers

- Tap Line Rubber Roller

- Chemical Resistance Rubber Roller

- EPDM Rubber Rollers

- BOPP Film Plant Rubber Roller

- Jockey Rubber Roller

- Raffia Machine Rubber Rollers

- Solventless Lamination Rubber Roller

- Packaging Rubber Roller

- Industrial Silicone Rubber Roller

- Adhesive Applicator Silicone Rubber Roller

- Hot Stamping Silicone Rubber Roller

- Printing Rubber Rollers

- Rubber Roller PTFE Coated

- Rubber Roller Ptfe Coated

- Flexo Gravure Printing Rubber Roller

- Synthetic Rubber Roller

- Air Shafts

- Carbon Fiber Air Shaft

- Air Shaft

- Quick Lock Shaft

- Core Shaft

- Air Expanding Shafts

- Leaf Type Air Expandable Shaft

- Lug Type Air Expandable Shaft

- Multi Bladder Shaft

- Multi Tube Air Shaft

- Multi Tube Shaft

- Ball Type Quick Lock Shafts

- Metalizer Air Shaft

- Core Air Shaft

- Cantilever Air Shaft

- Industrial Air Shaft

- Mechanical Air Expandable Shaft

- Rubber Expander Roller

- Aluminium or Wooden Slat Expanders

- Rubber Load Roller

- Polyband Expander Roller

- Rubber Expander Roller for Textile Industry

- Textile Rubber Expander Roller

- Curve Bar Expander Roller

- Rubber Expander Roller for Paper Industry

- Rubber Expander Roller

- Liquid Ammonia Expander Roller

- Pop Reel Rubber Expander Roller

- Industrial Textile Expanders

- Liquid Ammonia Rubber Expander Roller

- Rubber Expander Roller For Packaging Industry

- Curved Bar Rubber Expander Roller

- Variable bow roller

- Bow Rollers

- PU Roller

- Safety Chucks

- Embossing Roller

- PTFE Coated Roller

- PTFE Sleeve Coated Roller for Paper Industries

- Rubber Expander Roller with FEP PTFE Sleeve

- Rubber Expander With FEP PTFE Sleeve

- PTFE Expander Roller

- PTFE Coated Rubber Expander

- PTFE Sleeve Expander Roller

- PTFE Sleeve Coated Roller

- PTFE Sleeve Coated Roller For Paper Industries

- PTFE Sleeve Coated Bow Roller

- Air Expanding Shaft

- Hard Chrome Plated Roller

- Steel Rollers

- Banana Roller

- Core Holding Devices

- Air Chuck

- Differential Shafts

- Nip Rollers

- Anilox Roller

- Lock Shafts

- Aluminium Guide Rollers

- Lamination Rubber Roller

- Silicone Rubber Roller

- Rubber Sleeves

- Industrial Rollers

- Industrial Shafts

- Rubber Rollers

-

Applications

- Rubber Roller for Leather Industries

- Rubber Roller for Plastic Industries

- Rubber Roller for Textile Industries

- Rubber Roller for Paper Industries

- Rubber Roller for Metal Industries

- Quality

- Rubber Roller for Packaging Industries

- Rubber Roller for Tyre-tube

- Rubber Roller for Wallpaper Industries

- Infrastructure & Facilities

- Exports

- Infrastructure & Facilities

- Exports

- Contact Us

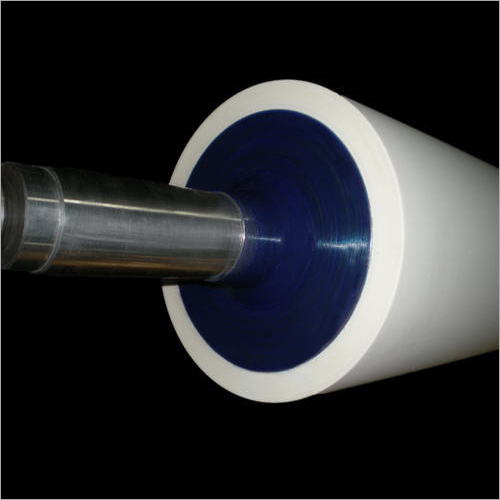

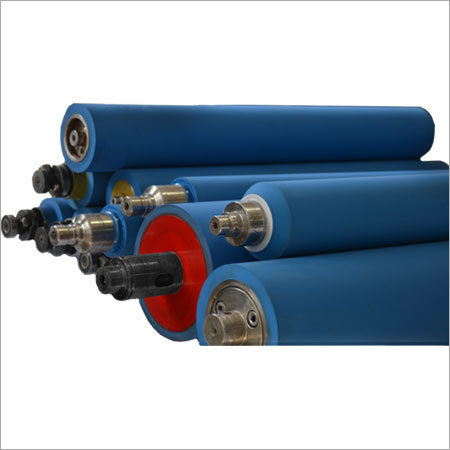

MDO Nip Roller

48000.00 INR/Piece

Product Details:

- Diameter 100 mm to 250 mm

- Capacity Up to 200 m/min Web Speed

- Material Rubber coated steel / Aluminum core

- Dimensions Customized as per requirement

- Technique Precision Machined, Dynamic Balanced

- Standard Industrial Grade

- Belt Width Upto 3000 mm

- Click to View more

X

MDO Nip Roller Price And Quantity

- 1 Piece

- 48000.00 INR/Piece

MDO Nip Roller Product Specifications

- Upto 3000 mm

- High-Precision Nip, Adjustable Pressure, Consistent Web Handling

- Precision Machined, Dynamic Balanced

- Rubber coated steel / Aluminum core

- Industrial Grade

- Up to 200 m/min Web Speed

- 100 mm to 250 mm

- Customized as per requirement

MDO Nip Roller Trade Information

- 5000 Piece Per Month

- 3 Week

Product Description

Technical specification

Roller Diameter | Max OD: 2000 mm |

Capacity | Custom |

Usage/Application | Printing Industry |

Model Name/Number | ART-1001 |

Roller Length | 8000mm |

Color | Any |

Brand | Anar |

Material | Rubber |

Packaging | Standard |

Engineered for Superior Performance

The MDO Nip Roller delivers high-precision web handling in demanding environments such as Mono Oriented Film plants and flexible packaging sectors. Incorporating a fine ground polished surface and adjustable pressure, it ensures reliable, uniform contact with the web while minimizing slippage and defects, even under substantial loads and elevated temperatures.

Customizable to Your Application Needs

Designed to cater to a variety of industrial settings, this nip roller offers broad customization for dimensions, end finishes, and mounting methods. With a roller length range of 500 mm to 3500 mm and diameter from 100 mm to 250 mm, it accommodates different film and web widths, meeting diverse application demands effectively.

Durable, High-Performance Construction

Using rubber-coated steel or aluminum cores, the roller is crafted to withstand solvent exposure, static generation, and temperatures up to 120C. Its dynamic balancing and precision machining guarantee smooth operation, contributing to extended equipment life and stable, high-speed production.

FAQs of MDO Nip Roller:

Q: How does the MDO Nip Roller improve web handling in production lines?

A: The MDO Nip Roller uses adjustable pressure and high-precision surface finishing to maintain consistent web tension and alignment, reducing the likelihood of wrinkles, slippage, or registration errors in film and flexible packaging production.Q: What applications is this nip roller suitable for?

A: It is primarily used in Mono Oriented Film (MDO) plants and flexible packaging industries, but its robust construction and anti-static, solvent-resistant features suit various web processing environments where high reliability and performance are required.Q: When should I consider using a fine ground and polished surface finish?

A: A fine ground and polished surface finish is recommended when smooth, uniform web contact is crucial for avoiding film damage or variation in material thickness, especially at higher web speeds and pressures.Q: Where can this nip roller be installed in an industrial setup?

A: The roller can be mounted using flanged shafts or journal bearings in both new and existing machinery across production lines that process films, papers, or laminates within its specified load, size, and temperature ranges.Q: What is the benefit of the anti-static and solvent-resistant coating?

A: These coatings enhance productivity by preventing static build-up (which attracts dust and can make handling difficult) and by protecting the roller surface from chemical attack in solvent-rich environments, thus extending equipment life.Q: How is the rollers pressure adjusted during operation?

A: Pressure can be manually or pneumatically adjusted based on the machines setup to suit the thickness and type of web material, ensuring optimal nip engagement and material quality.Q: What makes the MDO Nip Roller suitable for high-speed web processing?

A: Its dynamic balancing, precision machining, and robust construction support web speeds up to 200 m/min, minimizing vibration and maintaining smooth, consistent film transport at high throughput rates.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email