- Home Page

- Company Profile

-

Our Products

- Rubber Rollers

- Rubber Groove Spreader Roller

- Film Plant Roller

- Lamination Roller

- Carbon Fiber Roller

- Film Plant Rubber Rolls

- Etching Roller

- Cork Rollers

- Textile Printing Rubber Roller

- Polyurethane Rubber Roller

- Quick Change Sleeve Roller

- Godded Roller

- Rubber Coated Rollers

- Rotogravure Printing Rubber Rollers

- Rubber Grooved Spreader Rollers

- Rotogravure Printing Roller

- Rubber Roller For Foil

- Lamination Rubber Rollers

- Rubber Roller for Leather

- Rubber Spreader Roller

- Flexo Gravure Printing Rollers

- Industrial Rubber Roller

- Rubber Roller

- Flexographic Rubber Roller

- PU Rubber Roller

- Damping Rubber Roller

- Sucker Muller Rubber Roller

- Impression Rubber Roller

- Solvent Based Lamination Rubber Roller

- Ebonite Rubber Rollers

- Adhesive Coating Rubber Roller

- Intermediate Rubber Roller

- Hollow Rubber Roller

- VMCH Coating Rubber Roller

- Nitrile Rubber Rollers

- Printing Rubber Roller

- Rubber Roller for Tyre-tube

- Hypalon Rubber Rollers

- Tap Line Rubber Roller

- Chemical Resistance Rubber Roller

- EPDM Rubber Rollers

- BOPP Film Plant Rubber Roller

- Jockey Rubber Roller

- Raffia Machine Rubber Rollers

- Solventless Lamination Rubber Roller

- Packaging Rubber Roller

- Industrial Silicone Rubber Roller

- Adhesive Applicator Silicone Rubber Roller

- Hot Stamping Silicone Rubber Roller

- Printing Rubber Rollers

- Rubber Roller PTFE Coated

- Rubber Roller Ptfe Coated

- Flexo Gravure Printing Rubber Roller

- Synthetic Rubber Roller

- Air Shafts

- Carbon Fiber Air Shaft

- Air Shaft

- Quick Lock Shaft

- Core Shaft

- Air Expanding Shafts

- Leaf Type Air Expandable Shaft

- Lug Type Air Expandable Shaft

- Multi Bladder Shaft

- Multi Tube Air Shaft

- Multi Tube Shaft

- Ball Type Quick Lock Shafts

- Metalizer Air Shaft

- Core Air Shaft

- Cantilever Air Shaft

- Industrial Air Shaft

- Mechanical Air Expandable Shaft

- Rubber Expander Roller

- Aluminium or Wooden Slat Expanders

- Rubber Load Roller

- Polyband Expander Roller

- Rubber Expander Roller for Textile Industry

- Textile Rubber Expander Roller

- Curve Bar Expander Roller

- Rubber Expander Roller for Paper Industry

- Rubber Expander Roller

- Liquid Ammonia Expander Roller

- Industrial Textile Expanders

- Pop Reel Rubber Expander Roller

- Liquid Ammonia Rubber Expander Roller

- Rubber Expander Roller For Packaging Industry

- Curved Bar Rubber Expander Roller

- Variable bow roller

- Bow Rollers

- PU Roller

- Safety Chucks

- Embossing Roller

- PTFE Coated Roller

- PTFE Sleeve Coated Roller for Paper Industries

- Rubber Expander Roller with FEP PTFE Sleeve

- Rubber Expander With FEP PTFE Sleeve

- PTFE Expander Roller

- PTFE Coated Rubber Expander

- PTFE Sleeve Expander Roller

- PTFE Sleeve Coated Roller

- PTFE Sleeve Coated Roller For Paper Industries

- PTFE Sleeve Coated Bow Roller

- Air Expanding Shaft

- Hard Chrome Plated Roller

- Steel Rollers

- Banana Roller

- Core Holding Devices

- Air Chuck

- Differential Shafts

- Nip Rollers

- Anilox Roller

- Lock Shafts

- Aluminium Guide Rollers

- Lamination Rubber Roller

- Silicone Rubber Roller

- Rubber Sleeves

- Industrial Rollers

- Industrial Shafts

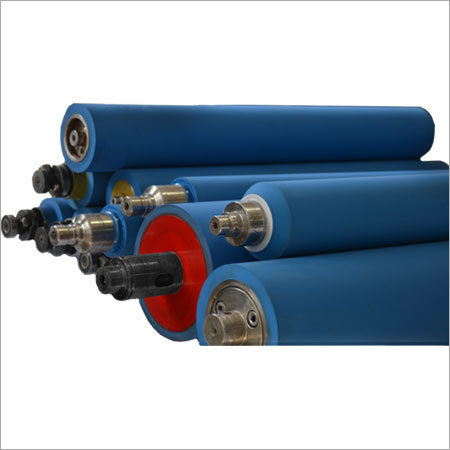

- Rubber Rollers

-

Applications

- Rubber Roller for Leather Industries

- Rubber Roller for Plastic Industries

- Rubber Roller for Textile Industries

- Rubber Roller for Paper Industries

- Rubber Roller for Metal Industries

- Quality

- Rubber Roller for Packaging Industries

- Rubber Roller for Tyre-tube

- Rubber Roller for Wallpaper Industries

- Infrastructure & Facilities

- Exports

- Infrastructure & Facilities

- Exports

- Contact Us

MDO Nip Rollers

16500.00 INR/Piece

Product Details:

- Diameter 75 mm to 250 mm

- Capacity Up to 500 kg/hr (varies by design)

- Material High-quality rubber-coated steel/aluminium

- Dimensions Tailor-made as per machine specifications

- Technique Advanced extrusion and precision balancing

- Standard Industrial Grade

- Belt Width Customizable (as per requirements)

- Click to View more

X

MDO Nip Rollers Price And Quantity

- 16500.00 INR/Piece

- 1 Piece

- Standard black or as specified

- Flange or foot mounting

- Heavy-duty, sealed ball bearings

- Smooth, wear-resistant

- 300 mm to 3000 mm (as per order)

- Up to 120°C

- Shore A 60-90 (as required)

- Corrosion and abrasion resistant coating

- Mono Oriented Film Line (MDO), plastic, textile, paper & packaging industries

MDO Nip Rollers Product Specifications

- Advanced extrusion and precision balancing

- Precise pressure control, uniform nip, minimal maintenance

- Customizable (as per requirements)

- High-quality rubber-coated steel/aluminium

- Tailor-made as per machine specifications

- Up to 500 kg/hr (varies by design)

- Industrial Grade

- 75 mm to 250 mm

- Standard black or as specified

- Flange or foot mounting

- Heavy-duty, sealed ball bearings

- Smooth, wear-resistant

- 300 mm to 3000 mm (as per order)

- Up to 120°C

- Shore A 60-90 (as required)

- Corrosion and abrasion resistant coating

- Mono Oriented Film Line (MDO), plastic, textile, paper & packaging industries

MDO Nip Rollers Trade Information

- 5000 Piece Per Month

- 3 Week

Product Description

MDO Nip rollers are used to join two or more sheets to create a laminated product. The tremendous pressure exerted at the nip point forces the sheets into close contact, squeezing out any bubbles or blisters that may cause a faulty connection. They are very effective and safe to use. MDO Nip rollers can be used to laminate sheets with wet adhesives, film adhesives, or hot melt glues or contact cement. To fulfil the diverse industrial requirements, it is available in a variety of sizes as well as custom-made sizes.

Technical specification

Roller Length | 200-300 mm,100-200 mm,0-100 mm,>500 mm,400-500 mm |

Roller Work Nature | Wetting With Rubber |

Color | Orange,White |

Brand | Anar |

Material | Rubber |

Roller Diameter | 0-50 mm,>250 mm |

Superior Performance and Versatility

Our MDO Nip Rollers are designed for exceptional efficiency in mono oriented film lines and other critical applications. With customizable sizing and precise engineering, they ensure high throughput and consistent results. Their adaptability to various belt widths and unique machine requirements makes them the preferred choice in multiple industries.

Durable Construction for Demanding Environments

Manufactured from high-quality rubber-coated steel or aluminium, these rollers are protected by special coatings for excellent resistance to wear, corrosion, and abrasion. The use of heavy-duty, sealed ball bearings and industrial-grade materials guarantees a long service lifespan, even under intensive operational conditions.

Advanced Engineering for Smooth Operation

Utilizing advanced extrusion and precision balancing techniques, each roller achieves uniform pressure distribution and minimal vibration. The smooth, wear-resistant surface finish enhances product quality while the robust mounting optionsflange or footsimplify installation and alignment.

FAQs of MDO Nip Rollers:

Q: How can I customize MDO Nip Rollers for my specific machine requirements?

A: MDO Nip Rollers can be customized in roller length (from 300 mm to 3000 mm), diameter (75 mm to 250 mm), belt width, hardness (Shore A 60-90), color, and mounting style. Please provide your machine specifications and desired features when ordering to ensure a perfect fit.Q: What is the primary benefit of using these rollers in mono oriented film lines and packaging industries?

A: These rollers deliver precise pressure control and uniform nip, crucial for consistent film thickness, minimal defects, and high-quality output. Their robust design and advanced surface finish help reduce maintenance needs and enhance operational efficiency in diverse industrial applications.Q: When is the ideal time to replace or upgrade MDO Nip Rollers?

A: It is advisable to consider replacement or upgrades when you notice irregular nip pressure, increased maintenance frequency, surface wear, or when your production line requires tailored rollers for new materials or higher throughput.Q: Where are these MDO Nip Rollers manufactured and supplied from?

A: We manufacture, export, and supply these MDO Nip Rollers from India, offering services worldwide for industrial clients across plastic, textile, paper, and packaging sectors.Q: What process is employed during the manufacturing of these rollers?

A: Our rollers are produced using advanced extrusion and precision balancing techniques to ensure uniform weight distribution, optimal surface smoothness, and long-term reliability for continuous industrial use.Q: How does the corrosion and abrasion-resistant coating benefit the user?

A: The specialized coating enhances roller durability by protecting against chemical exposure, wear, and environmental factors, resulting in extended operational life and reduced maintenance costs.Q: What type of mounting and bearing options are available?

A: MDO Nip Rollers are available with either flange or foot mounting to match your installation needs, and are fitted with heavy-duty, sealed ball bearings to ensure smooth, maintenance-free operation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email