- Home Page

- Company Profile

-

Our Products

- Rubber Rollers

- Textile Printing Rubber Roller

- Cork Rollers

- Film Plant Roller

- Carbon Fiber Roller

- Film Plant Rubber Rolls

- Rubber Groove Spreader Roller

- Etching Roller

- Lamination Roller

- Godded Roller

- Rubber Grooved Spreader Rollers

- Rotogravure Printing Rubber Rollers

- Polyurethane Rubber Roller

- Rubber Coated Rollers

- Quick Change Sleeve Roller

- Rotogravure Printing Roller

- Rubber Roller For Foil

- Lamination Rubber Rollers

- Rubber Spreader Roller

- Rubber Roller for Leather

- Flexo Gravure Printing Rollers

- Industrial Rubber Roller

- Flexographic Rubber Roller

- Rubber Roller

- PU Rubber Roller

- Damping Rubber Roller

- Sucker Muller Rubber Roller

- Impression Rubber Roller

- Solvent Based Lamination Rubber Roller

- Ebonite Rubber Rollers

- Adhesive Coating Rubber Roller

- Intermediate Rubber Roller

- Hollow Rubber Roller

- VMCH Coating Rubber Roller

- Nitrile Rubber Rollers

- Printing Rubber Roller

- Rubber Roller for Tyre-tube

- Hypalon Rubber Rollers

- Tap Line Rubber Roller

- Chemical Resistance Rubber Roller

- EPDM Rubber Rollers

- BOPP Film Plant Rubber Roller

- Jockey Rubber Roller

- Raffia Machine Rubber Rollers

- Solventless Lamination Rubber Roller

- Packaging Rubber Roller

- Industrial Silicone Rubber Roller

- Adhesive Applicator Silicone Rubber Roller

- Hot Stamping Silicone Rubber Roller

- Printing Rubber Rollers

- Rubber Roller PTFE Coated

- Rubber Roller Ptfe Coated

- Flexo Gravure Printing Rubber Roller

- Synthetic Rubber Roller

- Air Shafts

- Carbon Fiber Air Shaft

- Air Shaft

- Quick Lock Shaft

- Core Shaft

- Air Expanding Shafts

- Leaf Type Air Expandable Shaft

- Lug Type Air Expandable Shaft

- Multi Bladder Shaft

- Multi Tube Air Shaft

- Multi Tube Shaft

- Ball Type Quick Lock Shafts

- Metalizer Air Shaft

- Core Air Shaft

- Cantilever Air Shaft

- Industrial Air Shaft

- Mechanical Air Expandable Shaft

- Rubber Expander Roller

- Aluminium or Wooden Slat Expanders

- Rubber Load Roller

- Polyband Expander Roller

- Rubber Expander Roller for Textile Industry

- Textile Rubber Expander Roller

- Curve Bar Expander Roller

- Rubber Expander Roller for Paper Industry

- Rubber Expander Roller

- Liquid Ammonia Expander Roller

- Pop Reel Rubber Expander Roller

- Industrial Textile Expanders

- Liquid Ammonia Rubber Expander Roller

- Rubber Expander Roller For Packaging Industry

- Curved Bar Rubber Expander Roller

- Variable bow roller

- Bow Rollers

- PU Roller

- Safety Chucks

- Embossing Roller

- PTFE Coated Roller

- PTFE Sleeve Coated Roller for Paper Industries

- Rubber Expander Roller with FEP PTFE Sleeve

- Rubber Expander With FEP PTFE Sleeve

- PTFE Expander Roller

- PTFE Coated Rubber Expander

- PTFE Sleeve Expander Roller

- PTFE Sleeve Coated Roller

- PTFE Sleeve Coated Roller For Paper Industries

- PTFE Sleeve Coated Bow Roller

- Air Expanding Shaft

- Hard Chrome Plated Roller

- Steel Rollers

- Banana Roller

- Core Holding Devices

- Air Chuck

- Differential Shafts

- Nip Rollers

- Anilox Roller

- Lock Shafts

- Aluminium Guide Rollers

- Lamination Rubber Roller

- Silicone Rubber Roller

- Rubber Sleeves

- Industrial Rollers

- Industrial Shafts

- Rubber Rollers

-

Applications

- Rubber Roller for Leather Industries

- Rubber Roller for Plastic Industries

- Rubber Roller for Textile Industries

- Rubber Roller for Paper Industries

- Rubber Roller for Metal Industries

- Quality

- Rubber Roller for Packaging Industries

- Rubber Roller for Tyre-tube

- Rubber Roller for Wallpaper Industries

- Infrastructure & Facilities

- Exports

- Infrastructure & Facilities

- Exports

- Contact Us

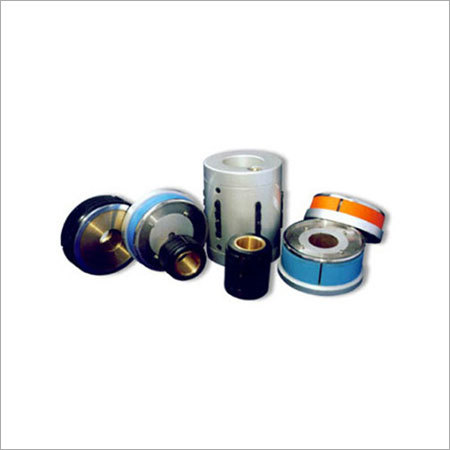

Mechanical Safety Chucks

25000.00 INR/Piece

Product Details:

- Product Type Mechanical Safety Chucks

- General Use Rotating shafts holding, web winding, and unwinding operations

- Material Other

- Type Flange / Foot Mounted

- Capacity Up to 2000 kg

- Weight (kg) Varies as per model

- Computerized No

- Click to View more

X

Mechanical Safety Chucks Price And Quantity

- 1 , , Piece

- 25000.00 INR/Piece

Mechanical Safety Chucks Product Specifications

- Flange / Foot Mounted

- Up to 2000 kg

- Silver / Metallic

- Quick coupling/decoupling, Low maintenance, High strength

- No

- No

- Mechanical Safety Chucks

- Varies as per model

- Manual

- Rotating shafts holding, web winding, and unwinding operations

- As per requirement

- 2

- No

- Other

Mechanical Safety Chucks Trade Information

- 500 , , Piece Per Month

- 21 Days

Product Description

Mechanical Safety Chuck designed by us, is used to rewind or unwind material in rolls on expanding airshafts. This chuck also allows for easier loading and unloading of rolls without having to move the airshaft directly. It acts as a device that allows you to keep your hands safe while working. Mechanical Safety Chuck cuts down on loading and unloading time. It provides maintenance-free operation since the driving mechanism does not need to be removed every time the core holding shaft is changed.

Versatile Mounting Options

Choose between foot and flange mount types for easy integration with your existing machinery and shaft arrangements. This flexibility simplifies installation and ensures compatibility across various applications in printing, packaging, textile, and paper industries.

Durable and Safe Performance

Built from hardened steel and treated with a corrosion-resistant coating, these safety chucks are engineered for long service life. The self-locking insertion slot system enhances safety, preventing accidental disengagement during operation and providing reliable shaft holding.

Efficient Operation and Low Maintenance

With a quick coupling and decoupling feature, you can swiftly change shafts with minimal downtime. Designed for manual operation, these chucks require low maintenance and operate efficiently at temperatures ranging from -20C to +80C, making them ideal for diverse industrial environments.

FAQs of Mechanical Safety Chucks:

Q: How do Mechanical Safety Chucks ensure secure holding during winding operations?

A: Mechanical Safety Chucks feature a self-locking insertion slot system which automatically secures the shaft when inserted, preventing accidental disengagement and ensuring continuous safe operation during winding and unwinding processes.Q: What shaft sizes and types are compatible with these safety chucks?

A: These chucks accommodate square or tri-lobe inserts ranging from 30 mm to 50 mm and are designed to fit different shaft diameters and configurations used in printing, packaging, textile, and paper applications.Q: When should I choose between the foot mount and flange mount options?

A: The choice depends on your machine setupfoot mounts are suitable for floor-level or base installation, whereas flange mounts are ideal for side or wall-mounted applications. Both options offer robust support and easy installation.Q: Where can these mechanical chucks be installed in the production line?

A: They are usually installed at the unwinding or winding stations of machinery in industries such as printing, packaging, textile, and paper & pulp, wherever reliable shaft holding and rapid shaft changes are required.Q: What is the maintenance process for these safety chucks?

A: Routine inspection, basic cleaning, and lubrication of moving parts are recommended. Due to their robust build with rust and corrosion-resistant coating, they require minimal maintenance compared to automated alternatives.Q: How does the quick coupling feature benefit my workflow?

A: Quick coupling/decoupling allows for fast shaft changes, reducing machine downtime and enhancing productivity, especially in high-volume web handling processes.Q: What advantages does the hardened steel insert material provide?

A: Hardened steel inserts offer high strength and wear resistance, ensuring that the safety chucks can withstand high torques (up to 1500 Nm) and operate reliably under heavy loads, contributing to long operational life.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email