- Home Page

- Company Profile

-

Our Products

- Rubber Rollers

- Textile Printing Rubber Roller

- Cork Rollers

- Film Plant Roller

- Carbon Fiber Roller

- Film Plant Rubber Rolls

- Rubber Groove Spreader Roller

- Etching Roller

- Lamination Roller

- Godded Roller

- Rubber Grooved Spreader Rollers

- Rotogravure Printing Rubber Rollers

- Polyurethane Rubber Roller

- Rubber Coated Rollers

- Quick Change Sleeve Roller

- Rotogravure Printing Roller

- Rubber Roller For Foil

- Lamination Rubber Rollers

- Rubber Spreader Roller

- Rubber Roller for Leather

- Flexo Gravure Printing Rollers

- Industrial Rubber Roller

- Flexographic Rubber Roller

- Rubber Roller

- PU Rubber Roller

- Damping Rubber Roller

- Sucker Muller Rubber Roller

- Impression Rubber Roller

- Solvent Based Lamination Rubber Roller

- Ebonite Rubber Rollers

- Adhesive Coating Rubber Roller

- Intermediate Rubber Roller

- Hollow Rubber Roller

- VMCH Coating Rubber Roller

- Nitrile Rubber Rollers

- Printing Rubber Roller

- Rubber Roller for Tyre-tube

- Hypalon Rubber Rollers

- Tap Line Rubber Roller

- Chemical Resistance Rubber Roller

- EPDM Rubber Rollers

- BOPP Film Plant Rubber Roller

- Jockey Rubber Roller

- Raffia Machine Rubber Rollers

- Solventless Lamination Rubber Roller

- Packaging Rubber Roller

- Industrial Silicone Rubber Roller

- Adhesive Applicator Silicone Rubber Roller

- Hot Stamping Silicone Rubber Roller

- Printing Rubber Rollers

- Rubber Roller PTFE Coated

- Rubber Roller Ptfe Coated

- Flexo Gravure Printing Rubber Roller

- Synthetic Rubber Roller

- Air Shafts

- Air Shaft

- Carbon Fiber Air Shaft

- Quick Lock Shaft

- Core Shaft

- Air Expanding Shafts

- Leaf Type Air Expandable Shaft

- Lug Type Air Expandable Shaft

- Multi Bladder Shaft

- Multi Tube Air Shaft

- Multi Tube Shaft

- Ball Type Quick Lock Shafts

- Metalizer Air Shaft

- Core Air Shaft

- Cantilever Air Shaft

- Industrial Air Shaft

- Mechanical Air Expandable Shaft

- Rubber Expander Roller

- Aluminium or Wooden Slat Expanders

- Rubber Load Roller

- Polyband Expander Roller

- Rubber Expander Roller for Textile Industry

- Textile Rubber Expander Roller

- Curve Bar Expander Roller

- Rubber Expander Roller for Paper Industry

- Rubber Expander Roller

- Liquid Ammonia Expander Roller

- Pop Reel Rubber Expander Roller

- Industrial Textile Expanders

- Liquid Ammonia Rubber Expander Roller

- Rubber Expander Roller For Packaging Industry

- Curved Bar Rubber Expander Roller

- Variable bow roller

- Bow Rollers

- PU Roller

- Safety Chucks

- Embossing Roller

- PTFE Coated Roller

- PTFE Sleeve Coated Roller for Paper Industries

- Rubber Expander Roller with FEP PTFE Sleeve

- Rubber Expander With FEP PTFE Sleeve

- PTFE Expander Roller

- PTFE Coated Rubber Expander

- PTFE Sleeve Expander Roller

- PTFE Sleeve Coated Roller

- PTFE Sleeve Coated Roller For Paper Industries

- PTFE Sleeve Coated Bow Roller

- Air Expanding Shaft

- Hard Chrome Plated Roller

- Steel Rollers

- Banana Roller

- Core Holding Devices

- Air Chuck

- Differential Shafts

- Nip Rollers

- Anilox Roller

- Lock Shafts

- Aluminium Guide Rollers

- Lamination Rubber Roller

- Silicone Rubber Roller

- Rubber Sleeves

- Industrial Rollers

- Industrial Shafts

- Rubber Rollers

-

Applications

- Rubber Roller for Leather Industries

- Rubber Roller for Plastic Industries

- Rubber Roller for Textile Industries

- Rubber Roller for Paper Industries

- Rubber Roller for Metal Industries

- Quality

- Rubber Roller for Packaging Industries

- Rubber Roller for Tyre-tube

- Rubber Roller for Wallpaper Industries

- Infrastructure & Facilities

- Exports

- Infrastructure & Facilities

- Exports

- Contact Us

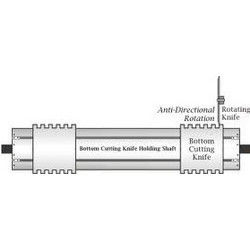

Multi Tube Shafts

48500.00 INR/Piece

Product Details:

- Material Alloy Steel

- Texture Type Smooth Finished

- Quality Level Industrial Grade

- Coating Anti-Corrosion Coated

- Length 300 mm - 1200 mm

- Diameter 40 mm - 120 mm

- Hardness HRC 60 2

- Click to View more

X

Multi Tube Shafts Price And Quantity

- 1 Piece

- 48500.00 INR/Piece

Multi Tube Shafts Product Specifications

- 0.015 mm

- 40 mm - 120 mm

- High Precision

- Industrial Grade

- HRC 60 2

- Anti-Corrosion Coated

- 4 mm - 12 mm

- Smooth Finished

- Alloy Steel

- 300 mm - 1200 mm

Multi Tube Shafts Trade Information

- 5000 Piece Per Month

- 3 Week

Product Description

Multi Tube Shafts are used in the printing and packaging industries. These items' bladders may be simply replaced if they get damaged. The main benefit of these goods is that their bodies are composed of stainless steel, which makes them durable and sturdy. These materials have a high resistance to corrosion. Multi Tube Shafts rely on the product's high accuracy for winding and unwinding processes. Built with cutting-edge technology, the device is efficient enough to run on many cores. They are available in a variety of price ranges and ranges on the market.

Technical specification

Application | Industrial |

Overall Length | 500 mm to 4000 mm |

Expanding Length | Customize |

Dimension/Size | Customize |

Outer Diameter | Customize |

Brand | Anar |

Color | Silver |

Material | Aluminum |

Usage/Application | Industrial |

Is It Replaceable | Not Replaceable |

Loading Capacity | upto 3 Ton |

Performance | High |

I Deal In | New Only |

Shape | Round |

Packaging Type | Wooden Box |

Superior Precision & Strength

Engineered with high-grade alloy steel and advanced CNC technology, our Multi Tube Shafts offer precise tolerance control, impressive tensile strength, and a flawless smooth finish. The shafts are designed to withstand heavy loads and rigorous industrial use, ensuring enhanced operational performance and longevity.

Versatile End Connections

We provide multiple options for shaft end connections, including flanged, keyed, and custom designs. This adaptability facilitates seamless integration into a wide range of machinery, catering to varied operational requirements in printing, paper, packaging, and textile sectors.

Reliable Anti-Corrosion Protection

With an anti-corrosion coated surface, our Multi Tube Shafts are protected against harsh working conditions and moisture. This feature significantly increases the products lifespan, reduces maintenance needs, and maintains consistency in quality over extended periods of use.

FAQs of Multi Tube Shafts:

Q: How are Multi Tube Shafts utilized in printing and packaging machinery?

A: Multi Tube Shafts serve as core components for rotation, tension and alignment in printing, packaging, and related machinery. Their high precision and rigidity support the smooth transmission of motion and stable mounting of rollers and print heads, maximizing machine efficiency and output quality.Q: What customization options are available for these shafts?

A: We offer extensive customization, including tube number, shaft length (300 mm to 1200 mm), diameter (40 mm to 120 mm), end connections (flanged, keyed, or custom), material, weight, and surface treatments. Designs can be tailored specifically to customer requirements for optimal fit and performance.Q: When is it beneficial to choose CNC machined and ground shafts for industrial applications?

A: CNC machined and ground shafts are ideal when superior dimensional accuracy, tight tolerances (0.01 mm), high tensile strength, and smooth surface finish are needed. They significantly improve mechanical reliability and product lifespan in high-demand environments.Q: Where are your Multi Tube Shafts manufactured and supplied from?

A: Our Multi Tube Shafts are manufactured, exported, and supplied from India. We serve as a comprehensive exporter, manufacturer, service provider, and supplier for industrial clients both domestically and internationally.Q: What process is involved in ensuring high hardness and roundness for these shafts?

A: The production process includes precision CNC machining, fine grinding, polishing, and heat treatment. These methods guarantee shaft hardness of HRC 60 2 and exceptional roundness ( 0.015 mm), contributing to smooth motion and wear resistance even under heavy load.Q: How does the anti-corrosion coating benefit the shaft in practical applications?

A: Anti-corrosion coating shields the shaft from moisture, chemicals, and abrasive conditions common in industrial environments. This protection reduces maintenance frequency, minimizes the risk of rust-related failure, and extends the overall lifespan of the component.Q: What quality standards do your Multi Tube Shafts adhere to?

A: Our Multi Tube Shafts are manufactured to industrial grade standards, ensuring consistent quality and reliability for demanding operations. Each shaft is precision-tested for tolerance, hardness, strength, and finish before shipment.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email