- Home Page

- Company Profile

-

Our Products

- Rubber Rollers

- Lamination Roller

- Film Plant Roller

- Textile Printing Rubber Roller

- Cork Rollers

- Etching Roller

- Carbon Fiber Roller

- Rubber Groove Spreader Roller

- Film Plant Rubber Rolls

- Godded Roller

- Rubber Coated Rollers

- Polyurethane Rubber Roller

- Quick Change Sleeve Roller

- Rotogravure Printing Rubber Rollers

- Rubber Grooved Spreader Rollers

- Rotogravure Printing Roller

- Rubber Roller For Foil

- Lamination Rubber Rollers

- Rubber Spreader Roller

- Rubber Roller for Leather

- Flexo Gravure Printing Rollers

- Industrial Rubber Roller

- Rubber Roller

- Flexographic Rubber Roller

- Damping Rubber Roller

- PU Rubber Roller

- Sucker Muller Rubber Roller

- Impression Rubber Roller

- Solvent Based Lamination Rubber Roller

- Ebonite Rubber Rollers

- Adhesive Coating Rubber Roller

- Intermediate Rubber Roller

- Hollow Rubber Roller

- VMCH Coating Rubber Roller

- Nitrile Rubber Rollers

- Printing Rubber Roller

- Rubber Roller for Tyre-tube

- Hypalon Rubber Rollers

- Tap Line Rubber Roller

- Chemical Resistance Rubber Roller

- EPDM Rubber Rollers

- BOPP Film Plant Rubber Roller

- Jockey Rubber Roller

- Raffia Machine Rubber Rollers

- Solventless Lamination Rubber Roller

- Packaging Rubber Roller

- Industrial Silicone Rubber Roller

- Adhesive Applicator Silicone Rubber Roller

- Hot Stamping Silicone Rubber Roller

- Printing Rubber Rollers

- Rubber Roller PTFE Coated

- Rubber Roller Ptfe Coated

- Flexo Gravure Printing Rubber Roller

- Synthetic Rubber Roller

- Air Shafts

- Air Shaft

- Carbon Fiber Air Shaft

- Quick Lock Shaft

- Core Shaft

- Air Expanding Shafts

- Leaf Type Air Expandable Shaft

- Lug Type Air Expandable Shaft

- Multi Bladder Shaft

- Multi Tube Air Shaft

- Multi Tube Shaft

- Ball Type Quick Lock Shafts

- Metalizer Air Shaft

- Core Air Shaft

- Cantilever Air Shaft

- Industrial Air Shaft

- Mechanical Air Expandable Shaft

- Rubber Expander Roller

- Aluminium or Wooden Slat Expanders

- Rubber Load Roller

- Polyband Expander Roller

- Rubber Expander Roller for Textile Industry

- Textile Rubber Expander Roller

- Curve Bar Expander Roller

- Rubber Expander Roller for Paper Industry

- Liquid Ammonia Expander Roller

- Rubber Expander Roller

- Industrial Textile Expanders

- Pop Reel Rubber Expander Roller

- Liquid Ammonia Rubber Expander Roller

- Rubber Expander Roller For Packaging Industry

- Curved Bar Rubber Expander Roller

- Variable bow roller

- Bow Rollers

- PU Roller

- Safety Chucks

- Embossing Roller

- PTFE Coated Roller

- PTFE Sleeve Coated Roller for Paper Industries

- Rubber Expander Roller with FEP PTFE Sleeve

- Rubber Expander With FEP PTFE Sleeve

- PTFE Expander Roller

- PTFE Coated Rubber Expander

- PTFE Sleeve Expander Roller

- PTFE Sleeve Coated Roller

- PTFE Sleeve Coated Roller For Paper Industries

- PTFE Sleeve Coated Bow Roller

- Air Expanding Shaft

- Hard Chrome Plated Roller

- Steel Rollers

- Banana Roller

- Core Holding Devices

- Air Chuck

- Differential Shafts

- Nip Rollers

- Anilox Roller

- Lock Shafts

- Aluminium Guide Rollers

- Lamination Rubber Roller

- Silicone Rubber Roller

- Rubber Sleeves

- Industrial Rollers

- Industrial Shafts

- Rubber Rollers

-

Applications

- Rubber Roller for Leather Industries

- Rubber Roller for Plastic Industries

- Rubber Roller for Textile Industries

- Rubber Roller for Paper Industries

- Rubber Roller for Metal Industries

- Quality

- Rubber Roller for Packaging Industries

- Rubber Roller for Tyre-tube

- Rubber Roller for Wallpaper Industries

- Infrastructure & Facilities

- Exports

- Infrastructure & Facilities

- Exports

- Contact Us

Pop Reel Rubber Expander Roller

18500.00 INR/Piece

Product Details:

- Condition New

- Structure Solid Cylindrical Roller with Steel Shaft

- Rubber Type High-Quality Synthetic Rubber

- Handle Material Mild Steel

- Handle Color Silver/Grey

- Pile Length Customizable as per requirement

- Weight Variable (Based on Size/Length)

- Click to View more

X

Pop Reel Rubber Expander Roller Price And Quantity

- 18500.00 INR/Piece

- 1 Piece

Pop Reel Rubber Expander Roller Product Specifications

- New

- Silver/Grey

- High-Quality Synthetic Rubber

- Customizable as per requirement

- Corrosion resistant, Durable, High surface finish, Uniform expansion, Smooth rotation

- Variable (Based on Size/Length)

- Solid Cylindrical Roller with Steel Shaft

- Mild Steel

Pop Reel Rubber Expander Roller Trade Information

- 5000 Piece Per Month

- 3 Week

Product Description

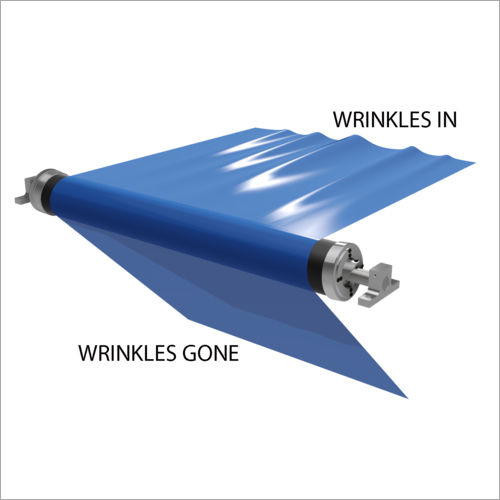

Our premium Pop Reel Rubber Expander Roller has bent shafts, sealed ball bearings, an abrasion-resistant sleeve, and metal segments. This roller is available in a variety of sizes and pricing to meet the needs of our clients. The major and most important advantage of this type of roller is that it is employed as a wrinkle-removal device in a wide range of industries. Pop Reel Rubber Expander Roller is checked under various parameters to ensure its high effectiveness. This product has an exceptional performance rate.

Technical specification

Load capacity | 100-500 Kg |

Brand | Anar |

Usage/Application | Textile Industries,Paper Industries,Film Plant |

Color | Black,Blue |

Diameter | Customize |

Material | Rubber |

Working temperature | -30 to 100 Degree C |

Precision-Engineered for Multiple Industries

The Pop Reel Rubber Expander Roller is meticulously designed to serve the ever-evolving demands of paper, textile, lamination, and printing sectors. Its solid cylindrical structure and ability to maintain high surface finish across a wide temperature range ensure reliability and consistency for your operational requirements.

Customization for Diverse Applications

Every production line is unique, which is why these rollers are available in multiple diameters and lengths, with end fittings tailored to your exact needsbe it flanged, plain, or keyed. Whether you need a mechanical or pneumatic expansion type, each unit is built to integrate seamlessly into your process.

FAQs of Pop Reel Rubber Expander Roller:

Q: How is the Pop Reel Rubber Expander Roller installed in existing machinery?

A: Installation is straightforward due to the rollers customizable end fittingsflanged, plain, or keyedallowing for seamless adaptation to your current equipment. Detailed fitting instructions are provided to ensure accurate and secure integration.Q: What benefits does using a high-quality synthetic rubber roller bring to printing or textile operations?

A: The high-quality synthetic rubber ensures exceptional durability, corrosion resistance, and a uniform expansion surface, providing smooth web handling and consistent results in demanding operational settings.Q: Where can these rollers be used effectively within industrial processes?

A: They are specifically engineered for use in paper converting, textile finishing, lamination systems, and printing presses, offering precise web stretching and alignment wherever expansion rollers are required.Q: When should I consider opting for pneumatic versus mechanical expansion types?

A: Pneumatic expansion is ideal for systems requiring rapid adjustment or higher responsiveness, while mechanical expansion suits applications with stable expansion requirements and minimal changes in roller tension.Q: What is the typical process for ordering a custom-fit Pop Reel Rubber Expander Roller?

A: You can provide your specifications for length, diameter, shaft material, end fitting type, pile length, and desired expansion type. The manufacturer then designs and fabricates the roller accordingly, ensuring full compliance with your requirements.Q: How does the roller maintain its performance under heavy load and elevated temperature?

A: Built with robust mild or stainless steel shafts, the roller is engineered to handle loads up to 800 kg and operate at temperatures up to 80C, while its synthetic rubber covering ensures consistent expansion and rotation even under demanding conditions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email