- Home Page

- Company Profile

-

Our Products

- Rubber Rollers

- Textile Printing Rubber Roller

- Cork Rollers

- Film Plant Roller

- Carbon Fiber Roller

- Film Plant Rubber Rolls

- Rubber Groove Spreader Roller

- Etching Roller

- Lamination Roller

- Godded Roller

- Rubber Grooved Spreader Rollers

- Rotogravure Printing Rubber Rollers

- Polyurethane Rubber Roller

- Rubber Coated Rollers

- Quick Change Sleeve Roller

- Rotogravure Printing Roller

- Rubber Roller For Foil

- Lamination Rubber Rollers

- Rubber Spreader Roller

- Rubber Roller for Leather

- Flexo Gravure Printing Rollers

- Industrial Rubber Roller

- Flexographic Rubber Roller

- Rubber Roller

- PU Rubber Roller

- Damping Rubber Roller

- Sucker Muller Rubber Roller

- Impression Rubber Roller

- Solvent Based Lamination Rubber Roller

- Ebonite Rubber Rollers

- Adhesive Coating Rubber Roller

- Intermediate Rubber Roller

- Hollow Rubber Roller

- VMCH Coating Rubber Roller

- Nitrile Rubber Rollers

- Printing Rubber Roller

- Rubber Roller for Tyre-tube

- Hypalon Rubber Rollers

- Tap Line Rubber Roller

- Chemical Resistance Rubber Roller

- EPDM Rubber Rollers

- BOPP Film Plant Rubber Roller

- Jockey Rubber Roller

- Raffia Machine Rubber Rollers

- Solventless Lamination Rubber Roller

- Packaging Rubber Roller

- Industrial Silicone Rubber Roller

- Adhesive Applicator Silicone Rubber Roller

- Hot Stamping Silicone Rubber Roller

- Printing Rubber Rollers

- Rubber Roller PTFE Coated

- Rubber Roller Ptfe Coated

- Flexo Gravure Printing Rubber Roller

- Synthetic Rubber Roller

- Air Shafts

- Air Shaft

- Carbon Fiber Air Shaft

- Quick Lock Shaft

- Core Shaft

- Air Expanding Shafts

- Leaf Type Air Expandable Shaft

- Lug Type Air Expandable Shaft

- Multi Bladder Shaft

- Multi Tube Air Shaft

- Multi Tube Shaft

- Ball Type Quick Lock Shafts

- Metalizer Air Shaft

- Core Air Shaft

- Cantilever Air Shaft

- Industrial Air Shaft

- Mechanical Air Expandable Shaft

- Rubber Expander Roller

- Aluminium or Wooden Slat Expanders

- Rubber Load Roller

- Polyband Expander Roller

- Rubber Expander Roller for Textile Industry

- Textile Rubber Expander Roller

- Curve Bar Expander Roller

- Rubber Expander Roller for Paper Industry

- Rubber Expander Roller

- Liquid Ammonia Expander Roller

- Pop Reel Rubber Expander Roller

- Industrial Textile Expanders

- Liquid Ammonia Rubber Expander Roller

- Rubber Expander Roller For Packaging Industry

- Curved Bar Rubber Expander Roller

- Variable bow roller

- Bow Rollers

- PU Roller

- Safety Chucks

- Embossing Roller

- PTFE Coated Roller

- PTFE Sleeve Coated Roller for Paper Industries

- Rubber Expander Roller with FEP PTFE Sleeve

- Rubber Expander With FEP PTFE Sleeve

- PTFE Expander Roller

- PTFE Coated Rubber Expander

- PTFE Sleeve Expander Roller

- PTFE Sleeve Coated Roller

- PTFE Sleeve Coated Roller For Paper Industries

- PTFE Sleeve Coated Bow Roller

- Air Expanding Shaft

- Hard Chrome Plated Roller

- Steel Rollers

- Banana Roller

- Core Holding Devices

- Air Chuck

- Differential Shafts

- Nip Rollers

- Anilox Roller

- Lock Shafts

- Aluminium Guide Rollers

- Lamination Rubber Roller

- Silicone Rubber Roller

- Rubber Sleeves

- Industrial Rollers

- Industrial Shafts

- Rubber Rollers

-

Applications

- Rubber Roller for Leather Industries

- Rubber Roller for Plastic Industries

- Rubber Roller for Textile Industries

- Rubber Roller for Paper Industries

- Rubber Roller for Metal Industries

- Quality

- Rubber Roller for Packaging Industries

- Rubber Roller for Tyre-tube

- Rubber Roller for Wallpaper Industries

- Infrastructure & Facilities

- Exports

- Infrastructure & Facilities

- Exports

- Contact Us

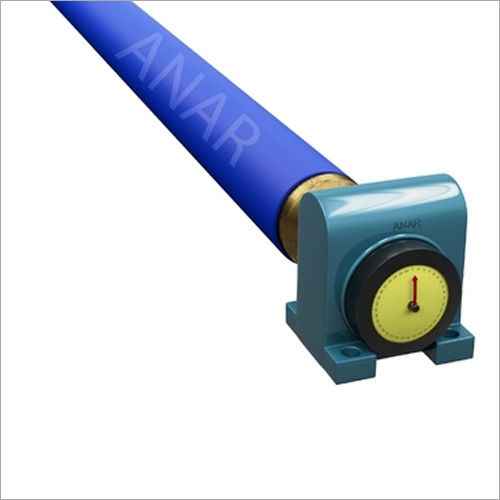

PTFE Sleeve Coated Bow Roller

36500.00 INR/Piece

Product Details:

- Capacity Up to 5000 kg

- Diameter 50 mm to 400 mm

- Material Mild Steel with PTFE Sleeve Coating

- Dimensions Customized as per requirement

- Technique Precision Machined with PTFE Coating

- Standard Industrial Grade

- Belt Width 100 mm to 1800 mm

- Click to View more

X

PTFE Sleeve Coated Bow Roller Price And Quantity

- 1 Piece

- 36500.00 INR/Piece

PTFE Sleeve Coated Bow Roller Product Specifications

- 50 mm to 400 mm

- Up to 5000 kg

- Corrosion Resistant, Low Friction, Non-stick Surface

- Mild Steel with PTFE Sleeve Coating

- 100 mm to 1800 mm

- Customized as per requirement

- Precision Machined with PTFE Coating

- Industrial Grade

PTFE Sleeve Coated Bow Roller Trade Information

- 5000 Piece Per Month

- 3 Week

Product Description

PTFE Sleeve Coated Bow Roller is a great technique to keep things from clinging to the surface. This bow roller is also used to avoid material intertwining during slitting processes. This sleeve was put over the roller and heated using a hot air pistol, causing the sleeve to shrink and accomplish the desired outcome. PTFE Sleeve Coated Bow Roller is created under the supervision of our skilled engineering staff. The most recent equipment ensures proper fit and quickly identifies material flaws.

Technical specification

Application | Paper Industries,Textile Industries |

Shore Hardness | 60 to 85 |

Port Of Dispatch | Mundra |

Delivery Time | 21 Days |

Hardness | 60 to 85 |

Color | Blue,Green |

Brand | Anar Rub Tech |

Material | Teflon Sleeve,Alu,M.S |

Max Dia | 200 mm |

Length | Up to 6 Mtr. |

Outer Diameter | 75 to 200 mm |

Precision Engineered for Versatile Applications

The PTFE Sleeve Coated Bow Roller is expertly crafted using precision machining techniques, combined with a durable PTFE coating over mild steel. This makes the roller suitable for a variety of high-demand environments such as conveyor systems, material handling, and the textile industry. Its robust build and customizable features ensure that it meets varied operational needs while maintaining consistent performance over prolonged periods.

Exceptional Surface Properties and Durability

With a smooth, non-stick PTFE surface, this bow roller dramatically reduces material build-up and friction. The high Shore D hardness rating, coupled with industrial-grade standards, provides outstanding resistance to wear and corrosion. Its exceptional working temperature range further contributes to dependable operation, even under extreme conditions, effectively minimizing maintenance and maximizing operational uptime.

FAQs of PTFE Sleeve Coated Bow Roller:

Q: How does the PTFE sleeve coating enhance roller performance in conveyor systems?

A: The PTFE sleeve provides a smooth, non-stick surface that reduces friction and prevents material from sticking to the roller. This minimizes product build-up, enhances conveyor belt life, and ensures smooth material transfer across various applications.Q: What is the recommended usage environment for this bow roller?

A: This roller is ideal for use in conveyor systems, material handling setups, and textile industries, especially where low friction, corrosion resistance, and a wide operational temperature range are required.Q: When should I consider a PTFE sleeve coated bow roller over a standard roller?

A: Opt for a PTFE sleeve coated roller when your processes demand minimal sticking, reduced friction, operation in extreme temperatures, or when handling sticky, delicate, or high-friction materials that could benefit from a non-stick surface.Q: Where can these rollers be installed, and what mounting options are available?

A: The bow rollers can be installed in a range of industrial settings. They are available with flange or foot mounting, offering flexibility for integration into existing or new conveyor and handling equipment.Q: What is the process for customizing roller dimensions for specific belt widths?

A: Each roller can be precision machined to meet particular requirements. Simply provide your necessary belt width (from 100 mm to 1800 mm) and diameter (50 mm to 400 mm), and the manufacturer will fabricate rollers to match your application needs.Q: How does the non-stick surface benefit material handling processes?

A: The non-stick PTFE sleeve reduces the risk of material adhesion, ensuring smoother handling of goods and easier cleaning, thus enhancing overall process efficiency and minimizing maintenance needs.Q: What maintenance is required for PTFE sleeve coated bow rollers?

A: These rollers are designed for low maintenance. Periodic inspections to check for physical damage or abnormal wear are generally sufficient, thanks to the PTFEs resistance to corrosion, sticking, and chemical exposure.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email