- Home Page

- Company Profile

-

Our Products

- Rubber Rollers

- Textile Printing Rubber Roller

- Cork Rollers

- Film Plant Roller

- Carbon Fiber Roller

- Film Plant Rubber Rolls

- Rubber Groove Spreader Roller

- Etching Roller

- Lamination Roller

- Godded Roller

- Rubber Grooved Spreader Rollers

- Rotogravure Printing Rubber Rollers

- Polyurethane Rubber Roller

- Rubber Coated Rollers

- Quick Change Sleeve Roller

- Rotogravure Printing Roller

- Rubber Roller For Foil

- Lamination Rubber Rollers

- Rubber Spreader Roller

- Rubber Roller for Leather

- Flexo Gravure Printing Rollers

- Industrial Rubber Roller

- Flexographic Rubber Roller

- Rubber Roller

- PU Rubber Roller

- Damping Rubber Roller

- Sucker Muller Rubber Roller

- Impression Rubber Roller

- Solvent Based Lamination Rubber Roller

- Ebonite Rubber Rollers

- Adhesive Coating Rubber Roller

- Intermediate Rubber Roller

- Hollow Rubber Roller

- VMCH Coating Rubber Roller

- Nitrile Rubber Rollers

- Printing Rubber Roller

- Rubber Roller for Tyre-tube

- Hypalon Rubber Rollers

- Tap Line Rubber Roller

- Chemical Resistance Rubber Roller

- EPDM Rubber Rollers

- BOPP Film Plant Rubber Roller

- Jockey Rubber Roller

- Raffia Machine Rubber Rollers

- Solventless Lamination Rubber Roller

- Packaging Rubber Roller

- Industrial Silicone Rubber Roller

- Adhesive Applicator Silicone Rubber Roller

- Hot Stamping Silicone Rubber Roller

- Printing Rubber Rollers

- Rubber Roller PTFE Coated

- Rubber Roller Ptfe Coated

- Flexo Gravure Printing Rubber Roller

- Synthetic Rubber Roller

- Air Shafts

- Air Shaft

- Carbon Fiber Air Shaft

- Quick Lock Shaft

- Core Shaft

- Air Expanding Shafts

- Leaf Type Air Expandable Shaft

- Lug Type Air Expandable Shaft

- Multi Bladder Shaft

- Multi Tube Air Shaft

- Multi Tube Shaft

- Ball Type Quick Lock Shafts

- Metalizer Air Shaft

- Core Air Shaft

- Cantilever Air Shaft

- Industrial Air Shaft

- Mechanical Air Expandable Shaft

- Rubber Expander Roller

- Aluminium or Wooden Slat Expanders

- Rubber Load Roller

- Polyband Expander Roller

- Rubber Expander Roller for Textile Industry

- Textile Rubber Expander Roller

- Curve Bar Expander Roller

- Rubber Expander Roller for Paper Industry

- Rubber Expander Roller

- Liquid Ammonia Expander Roller

- Pop Reel Rubber Expander Roller

- Industrial Textile Expanders

- Liquid Ammonia Rubber Expander Roller

- Rubber Expander Roller For Packaging Industry

- Curved Bar Rubber Expander Roller

- Variable bow roller

- Bow Rollers

- PU Roller

- Safety Chucks

- Embossing Roller

- PTFE Coated Roller

- PTFE Sleeve Coated Roller for Paper Industries

- Rubber Expander Roller with FEP PTFE Sleeve

- Rubber Expander With FEP PTFE Sleeve

- PTFE Expander Roller

- PTFE Coated Rubber Expander

- PTFE Sleeve Expander Roller

- PTFE Sleeve Coated Roller

- PTFE Sleeve Coated Roller For Paper Industries

- PTFE Sleeve Coated Bow Roller

- Air Expanding Shaft

- Hard Chrome Plated Roller

- Steel Rollers

- Banana Roller

- Core Holding Devices

- Air Chuck

- Differential Shafts

- Nip Rollers

- Anilox Roller

- Lock Shafts

- Aluminium Guide Rollers

- Lamination Rubber Roller

- Silicone Rubber Roller

- Rubber Sleeves

- Industrial Rollers

- Industrial Shafts

- Rubber Rollers

-

Applications

- Rubber Roller for Leather Industries

- Rubber Roller for Plastic Industries

- Rubber Roller for Textile Industries

- Rubber Roller for Paper Industries

- Rubber Roller for Metal Industries

- Quality

- Rubber Roller for Packaging Industries

- Rubber Roller for Tyre-tube

- Rubber Roller for Wallpaper Industries

- Infrastructure & Facilities

- Exports

- Infrastructure & Facilities

- Exports

- Contact Us

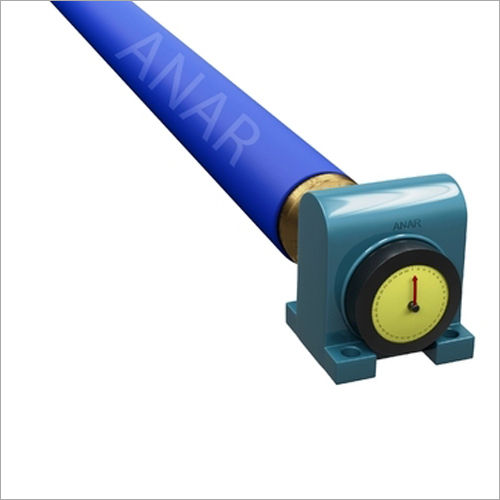

Rubber Expander Roller with FEP PTFE Sleeve

4000.00 - 24000.00 INR/Piece

Product Details:

- Capacity Suitable for light to heavy duty web handling

- Diameter 50 mm to 300 mm

- Material Rubber with FEP/PTFE sleeve

- Dimensions Length: 300 mm to 6000 mm

- Technique Precision engineered with seamless PTFE/FEP sleeve

- Standard Customizable as per requirement

- Belt Width Up to 2200 mm

- Click to View more

X

Rubber Expander Roller with FEP PTFE Sleeve Price And Quantity

- 4000.00 - 24000.00 INR/Piece

- 1 , , Piece

Rubber Expander Roller with FEP PTFE Sleeve Product Specifications

- Up to 2200 mm

- Precision engineered with seamless PTFE/FEP sleeve

- Customizable as per requirement

- Abrasion resistant, Chemical resistant, Anti-stick surface

- Length: 300 mm to 6000 mm

- 50 mm to 300 mm

- Rubber with FEP/PTFE sleeve

- Suitable for light to heavy duty web handling

Rubber Expander Roller with FEP PTFE Sleeve Trade Information

- 500 , , Piece Per Month

- 21 Days

Product Description

An industrial roller called a rubber expander roller is an essential component that plays an important part in the machining process. It is required to feed and guide raw material into a machine, mainly printing, coating, and laminating while making sure that there is enough tension and pressure. The expander roller made from roller comes with an FEP PTFE sleeve for letting the material pass through the roller without sticking to it and causing any kind of damage. A durable and reliable rubber expander roller with an FEP PTFE sleeve is supplied to paper, printing, plastic, and many other industries.

Exceptional Durability and Chemical Resistance

The FEP/PTFE sleeve on this expander roller offers outstanding protection against chemicals, abrasion, and corrosion, extending the rollers service life even in aggressive operating conditions. The non-stick surface prevents material build-up, reduces maintenance needs, and ensures flawless, consistent operation throughout various processes.

Precision Engineering for Web Handling

Each roller is manufactured to strict toleranceseccentricity is kept under 0.05 mmdelivering accurate runout vital for high-speed web handling applications. With precision engineering and seamless PTFE/FEP coverage, these rollers maintain consistent pressure and alignment, optimizing product quality and process efficiency.

Versatile Customization Options

We offer a wide selection of core materials, surface hardness values, mounting methods, and dimensions. The rollers can be tailored for specific operational conditions and customer requirements, ensuring compatibility and peak performance in diverse industries such as textiles, nonwovens, packaging, and paper. Custom color options are available on request to match your operational aesthetics or coding needs.

FAQs of Rubber Expander Roller with FEP PTFE Sleeve:

Q: How does the FEP/PTFE sleeve enhance the performance of the Rubber Expander Roller?

A: The FEP/PTFE sleeve provides a smooth, glossy, anti-adhesive surface that resists chemicals, abrasion, and sticking, making it ideal for high-temperature and demanding industrial processes. This ensures longer service life, less downtime, and low maintenance costs.Q: What applications are best suited for these expander rollers?

A: These rollers are designed for use in textile, paper, packaging, plastic film, and non-woven processing industries. Their chemical resistance and precise engineering make them especially suitable for web handling tasks where uniform tension and anti-stick properties are essential.Q: When should the sleeve thickness or hardness be customized?

A: Customization is recommended when your process requires specific pressure, grip, or resistance to chemicals. Choosing the appropriate sleeve thickness (0.52.0 mm) and surface hardness (Shore A 25 to 95) optimizes roller performance for unique operating conditions or materials.Q: Where can these rollers be installed within an industrial process?

A: Rubber Expander Rollers with FEP/PTFE sleeves can be mounted using flange or journal type end fittings, making them adaptable for various machine setups across conveyor lines, web presses, coating machines, and laminators in your facility.Q: What is the process for manufacturing these precision-engineered rollers?

A: Each roller is carefully crafted with seamless PTFE/FEP sleeves over a choice of mild steel, stainless steel, or aluminum core. Advanced techniques ensure accurate dimensions (diameter 50300 mm, length 3006000 mm) and precise eccentricity (< 0.05 mm), resulting in high-quality, reliable rollers.Q: How does the anti-stick surface benefit industrial operations?

A: The anti-stick properties of the FEP/PTFE sleeve prevent material build-up and sticking issues, which helps maintain consistent web movement, reduces cleaning and maintenance needs, and minimizes risks of defects during processing.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email