- Home Page

- Company Profile

-

Our Products

- Rubber Rollers

- Lamination Roller

- Film Plant Roller

- Textile Printing Rubber Roller

- Cork Rollers

- Etching Roller

- Carbon Fiber Roller

- Rubber Groove Spreader Roller

- Film Plant Rubber Rolls

- Godded Roller

- Rubber Coated Rollers

- Polyurethane Rubber Roller

- Quick Change Sleeve Roller

- Rotogravure Printing Rubber Rollers

- Rubber Grooved Spreader Rollers

- Rotogravure Printing Roller

- Rubber Roller For Foil

- Lamination Rubber Rollers

- Rubber Spreader Roller

- Rubber Roller for Leather

- Flexo Gravure Printing Rollers

- Industrial Rubber Roller

- Rubber Roller

- Flexographic Rubber Roller

- Damping Rubber Roller

- PU Rubber Roller

- Sucker Muller Rubber Roller

- Impression Rubber Roller

- Solvent Based Lamination Rubber Roller

- Ebonite Rubber Rollers

- Adhesive Coating Rubber Roller

- Intermediate Rubber Roller

- Hollow Rubber Roller

- VMCH Coating Rubber Roller

- Nitrile Rubber Rollers

- Printing Rubber Roller

- Rubber Roller for Tyre-tube

- Hypalon Rubber Rollers

- Tap Line Rubber Roller

- Chemical Resistance Rubber Roller

- EPDM Rubber Rollers

- BOPP Film Plant Rubber Roller

- Jockey Rubber Roller

- Raffia Machine Rubber Rollers

- Solventless Lamination Rubber Roller

- Packaging Rubber Roller

- Industrial Silicone Rubber Roller

- Adhesive Applicator Silicone Rubber Roller

- Hot Stamping Silicone Rubber Roller

- Printing Rubber Rollers

- Rubber Roller PTFE Coated

- Rubber Roller Ptfe Coated

- Flexo Gravure Printing Rubber Roller

- Synthetic Rubber Roller

- Air Shafts

- Air Shaft

- Carbon Fiber Air Shaft

- Quick Lock Shaft

- Core Shaft

- Air Expanding Shafts

- Leaf Type Air Expandable Shaft

- Lug Type Air Expandable Shaft

- Multi Bladder Shaft

- Multi Tube Air Shaft

- Multi Tube Shaft

- Ball Type Quick Lock Shafts

- Metalizer Air Shaft

- Core Air Shaft

- Cantilever Air Shaft

- Industrial Air Shaft

- Mechanical Air Expandable Shaft

- Rubber Expander Roller

- Aluminium or Wooden Slat Expanders

- Rubber Load Roller

- Polyband Expander Roller

- Rubber Expander Roller for Textile Industry

- Textile Rubber Expander Roller

- Curve Bar Expander Roller

- Rubber Expander Roller for Paper Industry

- Liquid Ammonia Expander Roller

- Rubber Expander Roller

- Industrial Textile Expanders

- Pop Reel Rubber Expander Roller

- Liquid Ammonia Rubber Expander Roller

- Rubber Expander Roller For Packaging Industry

- Curved Bar Rubber Expander Roller

- Variable bow roller

- Bow Rollers

- PU Roller

- Safety Chucks

- Embossing Roller

- PTFE Coated Roller

- PTFE Sleeve Coated Roller for Paper Industries

- Rubber Expander Roller with FEP PTFE Sleeve

- Rubber Expander With FEP PTFE Sleeve

- PTFE Expander Roller

- PTFE Coated Rubber Expander

- PTFE Sleeve Expander Roller

- PTFE Sleeve Coated Roller

- PTFE Sleeve Coated Roller For Paper Industries

- PTFE Sleeve Coated Bow Roller

- Air Expanding Shaft

- Hard Chrome Plated Roller

- Steel Rollers

- Banana Roller

- Core Holding Devices

- Air Chuck

- Differential Shafts

- Nip Rollers

- Anilox Roller

- Lock Shafts

- Aluminium Guide Rollers

- Lamination Rubber Roller

- Silicone Rubber Roller

- Rubber Sleeves

- Industrial Rollers

- Industrial Shafts

- Rubber Rollers

-

Applications

- Rubber Roller for Leather Industries

- Rubber Roller for Plastic Industries

- Rubber Roller for Textile Industries

- Rubber Roller for Paper Industries

- Rubber Roller for Metal Industries

- Quality

- Rubber Roller for Packaging Industries

- Rubber Roller for Tyre-tube

- Rubber Roller for Wallpaper Industries

- Infrastructure & Facilities

- Exports

- Infrastructure & Facilities

- Exports

- Contact Us

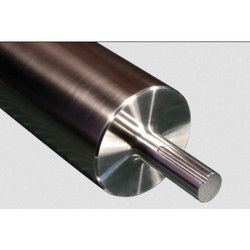

Aluminium Rollers

6700.00 INR/Piece

Product Details:

- Finish Polished/Anodized

- Length Up to 6000 mm

- Features Lightweight, Durable, Precision Balanced, Low Maintenance

- Thickness 2 mm - 10 mm

- Fabrication Process Extrusion, Machining

- Corrosion Resistant Yes

- Material Aluminium

- Click to View more

X

Aluminium Rollers Price And Quantity

- 1 Piece

- 6700.00 INR/Piece

Aluminium Rollers Product Specifications

- T6

- Aluminium Roller

- 50 mm - 300 mm

- AA Grade

- High

- 95 HB

- Up to 300 mm

- Custom sizes available

- Standard & Custom

- As per customer specification

- Silver

- 6061

- Textile, Packaging, Printing, Food Processing, Industrial Conveyors

- Up to 6000 mm

- Polished/Anodized

- Varies as per requirement

- Round

- Extrusion, Machining

- Lightweight, Durable, Precision Balanced, Low Maintenance

- Yes

- 2 mm - 10 mm

- Anodized

- Aluminium

- Yes

Aluminium Rollers Trade Information

- 500 Piece Per Month

- 500 Week

Product Description

Our Aluminium Rollers are generally praised for their great design. To ensure quality, the full line of these rollers is manufactured in compliance with industry standards. Furthermore, we perform stringent checks to provide the industry with a perfect collection of these products. Industrial rollers are thoroughly examined. Because thorough quality assurance is standard, each manufacturing step is recorded. Aluminium Rollers are made to the exact needs of our customers. They are created in close collaboration with the end user.

Technical specification

Application | Engineering |

Roller Diameter | Customize |

Roller Length | Customize |

Roller Material | Aluminium |

Color | Black, Silver |

Brand | Anar |

Material | Aluminium |

Type | Roller |

Superior Strength & Durability

Crafted from 6061-T6 aluminium alloy, our rollers ensure high durability and long service life, boasting a minimum tensile strength of 260 MPa and a hardness of 95 HB. The anodized surface not only offers a polished, premium finish, but also delivers exceptional resistance to corrosion, making these rollers ideal for demanding industrial environments.

Custom Engineered for Versatility

Available in a broad range of custom diameters (50300 mm) and lengths (up to 6000 mm), with thicknesses from 2 mm to 10 mm, our aluminium rollers accommodate unique customer specifications. Both standard and custom end fittings are offered to ensure seamless integration into existing equipment across textile, packaging, printing, food processing, and industrial conveyor systems.

Precision Balancing & Easy Maintenance

Each roller undergoes precision balancing with accuracy up to 1 g mm and adheres to a strict concentricity tolerance of 0.02 mm. Lightweight yet robust, our rollers are designed for easy cleaning and assembly, minimizing downtime and maintenance costs while delivering optimum operational efficiency.

FAQs of Aluminium Rollers:

Q: How are the aluminium rollers manufactured and finished for quality assurance?

A: Our aluminium rollers are produced using advanced extrusion and machining processes, followed by anodizing for a polished, corrosion-resistant finish. Each roller undergoes strict quality checks, including balancing accuracy (up to 1 g mm) and a concentricity tolerance of 0.02 mm, to ensure reliable performance in industrial environments.Q: What are the key benefits of choosing these rollers for industrial applications?

A: These rollers offer high tensile strength, low weight, outstanding corrosion resistance, and is precision balanced for smooth operation. Their easy-to-clean and maintain design reduces downtime, while custom sizing and various mounting options ensure compatibility across multiple industries, including textiles, packaging, and food processing.Q: When should aluminium rollers with steel or aluminium inserts be preferred?

A: Aluminium rollers with steel or aluminium inserts should be selected when high strength-to-weight ratio and precision are critical, particularly in applications where rollers endure heavy loads, varying temperatures (-20C to +120C), or require minimal maintenance and enhanced operational lifespan.Q: Where can these rollers be installed or used most effectively?

A: Our rollers are designed for versatile use across textile machinery, packaging lines, printing presses, food processing equipment, and industrial conveyors. They are suitable wherever precision handling, smooth rotation, and robust performance are essential.Q: What mounting and size options are available for these rollers?

A: We offer both standard and custom end fittings to facilitate secure mounting in most industrial systems. Diameters range from 50 mm to 300 mm, lengths up to 6000 mm, and wall thickness between 2 mm and 10 mm. Custom dimensions are available upon request to ensure a perfect fit.Q: How can the rollers be maintained and cleaned for optimal performance?

A: The rollers are designed for easy disassembly and cleaning. Their anodized and polished surfaces resist material buildup, allowing simple wipe-down or wash routines. Routine inspection and basic cleaning are typically sufficient to maintain long-term efficiency and extend service life.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email