- Home Page

- Company Profile

-

Our Products

- Rubber Rollers

- Lamination Roller

- Film Plant Roller

- Textile Printing Rubber Roller

- Cork Rollers

- Etching Roller

- Carbon Fiber Roller

- Rubber Groove Spreader Roller

- Film Plant Rubber Rolls

- Godded Roller

- Rubber Coated Rollers

- Polyurethane Rubber Roller

- Quick Change Sleeve Roller

- Rotogravure Printing Rubber Rollers

- Rubber Grooved Spreader Rollers

- Rotogravure Printing Roller

- Rubber Roller For Foil

- Lamination Rubber Rollers

- Rubber Spreader Roller

- Rubber Roller for Leather

- Flexo Gravure Printing Rollers

- Industrial Rubber Roller

- Rubber Roller

- Flexographic Rubber Roller

- Damping Rubber Roller

- PU Rubber Roller

- Sucker Muller Rubber Roller

- Impression Rubber Roller

- Solvent Based Lamination Rubber Roller

- Ebonite Rubber Rollers

- Adhesive Coating Rubber Roller

- Intermediate Rubber Roller

- Hollow Rubber Roller

- VMCH Coating Rubber Roller

- Nitrile Rubber Rollers

- Printing Rubber Roller

- Rubber Roller for Tyre-tube

- Hypalon Rubber Rollers

- Tap Line Rubber Roller

- Chemical Resistance Rubber Roller

- EPDM Rubber Rollers

- BOPP Film Plant Rubber Roller

- Jockey Rubber Roller

- Raffia Machine Rubber Rollers

- Solventless Lamination Rubber Roller

- Packaging Rubber Roller

- Industrial Silicone Rubber Roller

- Adhesive Applicator Silicone Rubber Roller

- Hot Stamping Silicone Rubber Roller

- Printing Rubber Rollers

- Rubber Roller PTFE Coated

- Rubber Roller Ptfe Coated

- Flexo Gravure Printing Rubber Roller

- Synthetic Rubber Roller

- Air Shafts

- Air Shaft

- Carbon Fiber Air Shaft

- Quick Lock Shaft

- Core Shaft

- Air Expanding Shafts

- Leaf Type Air Expandable Shaft

- Lug Type Air Expandable Shaft

- Multi Bladder Shaft

- Multi Tube Air Shaft

- Multi Tube Shaft

- Ball Type Quick Lock Shafts

- Metalizer Air Shaft

- Core Air Shaft

- Cantilever Air Shaft

- Industrial Air Shaft

- Mechanical Air Expandable Shaft

- Rubber Expander Roller

- Aluminium or Wooden Slat Expanders

- Rubber Load Roller

- Polyband Expander Roller

- Rubber Expander Roller for Textile Industry

- Textile Rubber Expander Roller

- Curve Bar Expander Roller

- Rubber Expander Roller for Paper Industry

- Liquid Ammonia Expander Roller

- Rubber Expander Roller

- Industrial Textile Expanders

- Pop Reel Rubber Expander Roller

- Liquid Ammonia Rubber Expander Roller

- Rubber Expander Roller For Packaging Industry

- Curved Bar Rubber Expander Roller

- Variable bow roller

- Bow Rollers

- PU Roller

- Safety Chucks

- Embossing Roller

- PTFE Coated Roller

- PTFE Sleeve Coated Roller for Paper Industries

- Rubber Expander Roller with FEP PTFE Sleeve

- Rubber Expander With FEP PTFE Sleeve

- PTFE Expander Roller

- PTFE Coated Rubber Expander

- PTFE Sleeve Expander Roller

- PTFE Sleeve Coated Roller

- PTFE Sleeve Coated Roller For Paper Industries

- PTFE Sleeve Coated Bow Roller

- Air Expanding Shaft

- Hard Chrome Plated Roller

- Steel Rollers

- Banana Roller

- Core Holding Devices

- Air Chuck

- Differential Shafts

- Nip Rollers

- Anilox Roller

- Lock Shafts

- Aluminium Guide Rollers

- Lamination Rubber Roller

- Silicone Rubber Roller

- Rubber Sleeves

- Industrial Rollers

- Industrial Shafts

- Rubber Rollers

-

Applications

- Rubber Roller for Leather Industries

- Rubber Roller for Plastic Industries

- Rubber Roller for Textile Industries

- Rubber Roller for Paper Industries

- Rubber Roller for Metal Industries

- Quality

- Rubber Roller for Packaging Industries

- Rubber Roller for Tyre-tube

- Rubber Roller for Wallpaper Industries

- Infrastructure & Facilities

- Exports

- Infrastructure & Facilities

- Exports

- Contact Us

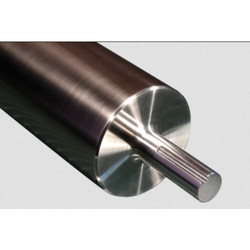

Aluminium Guide Rollers

6700.00 INR/Piece

Product Details:

- Size Available in various sizes

- Temper T6

- Width Customizable

- Outer Diameter Up to 300 mm

- Finish Smooth

- Material Aluminium

- Features Lightweight, long life, rust proof, precision balanced

- Click to View more

X

Aluminium Guide Rollers Price And Quantity

- 6700.00 INR/Piece

- 1 Piece

Aluminium Guide Rollers Product Specifications

- High tensile

- Available in various sizes

- Brinell 95 HB

- Customizable

- Up to 300 mm

- T6

- Smooth

- Cylindrical

- Customized as per requirement

- Range: 2 mm to 10 mm

- Lightweight, long life, rust proof, precision balanced

- Guide Roller

- Anodized/Polished

- Aluminium

- Aluminium Alloy

- Range: 50 mm to 300 mm

- Extruded and machined

- Aluminium 6000 series

- Silver (Standard), Customized on request

- 6061

- As per drawing/specification

- Yes

- Range: 100 mm to 3000 mm

- Industrial conveyors, textile machinery, packaging, printing, paper, and allied machinery

Aluminium Guide Rollers Trade Information

- 500 Piece Per Month

- 3 Week

Product Description

With extensive expertise in this domain we are engaged in offering our clients superior and durable range of Aluminum Guide Roller. Offered roller is made using high grade materials and latest techniques by dexterous professionals as per industry norms. It is widely used in plastic and textile machinery industries. Our provided roller has excellent ink transfer property, uniform hardness over all the surface, has dimensional accuracy and perfect binding to metal core. Aluminum Guide Roller is available in different types of length and diameter depending upon the requirements.

Frequently Asked Questions:

1. What is the reason for an Aluminum Guide Roller?

Ans. Guide rollers and rolls also referred to as idher rollers, are used to properly align components and substances with their supposed pathway or tune while transferring via machinery or device.

2. How do you hold Aluminum Guide Roller?

Ans. To preserve your rollers turning freely, always flush the whole manual (and tip-top) with clean water whenever you come back to the dock.

3. Which energy is used for rolling mills?

Ans. Electrical energy is used at once in an important rolling process for the shaping of hot billets into the rolled products (rolling mills, and shears and so forth.), in reheating furnace (coal pulverizer, blower, and pusher and many others.)

Superior Performance across Industries

Engineered for versatility, our aluminium guide rollers excel in diverse industrial sectors. From conveyor systems and packaging lines to textile and printing machinery, these rollers enhance operational efficiency by offering strength, corrosion resistance, and smooth movement. Their compatibility with both horizontal and vertical installations ensures seamless integration into new or existing setups, regardless of the industry requirements.

Custom Solutions and Reliable Quality

We understand every operation has unique needs. Thats why our rollers are available in a broad spectrum of lengths, diameters, and surface treatments. Clients may select from standard or customized end fittings and packaging options. Our commitment to ISO 9001:2015 certified manufacturing means every roller promises precise balance, minimal maintenance, and longer operational life, reinforcing your investment with consistent quality and reliability.

FAQs of Aluminium Guide Rollers:

Q: How are aluminium guide rollers installed in industrial equipment?

A: Aluminium guide rollers are designed for flexible installation and can be fitted horizontally or vertically. Their end fittings can be either standard or customized, ensuring compatibility with various equipment designs and mounting specifications. Detailed installation instructions and support are provided with each order for smooth setup.Q: What are the main benefits of using aluminium guide rollers with ball or plain bearings?

A: These rollers offer high tensile strength, lightweight construction, and superior resistance to corrosion. With ball or plain bearing options, they ensure smooth rotation, low friction, minimal maintenance, and optimal performance across temperature extremes. Their precision balance reduces vibration, thereby enhancing machinery life.Q: When is customization necessary for end fittings or roller dimensions?

A: Customization is recommended when your application requires specific lengths, diameters, widths, or unique mounting configurations that standard rollers do not cover. Our engineering team can tailor these attributes, including end fittings and packaging, based on your machinery or process requirements.Q: Where can these aluminium guide rollers be used?

A: These rollers are ideal for use in a wide range of industries, such as industrial conveyor systems, textile machinery, packaging equipment, printing presses, and paper processing units. Their adaptability and durability make them suitable for both new installations and upgrades in existing machinery.Q: What is the fabrication process for these guide rollers?

A: Our rollers are manufactured through an extrusion process using high-grade aluminium 6000 series, followed by precision machining to achieve accurate dimensions and balance. Surface treatments like anodizing or polishing are applied for added durability and smooth finish, ensuring reliability and enhanced lifespan.Q: How does the lubrication-free option improve maintenance?

A: The lubrication-free design eliminates the need for regular greasing, reducing overall maintenance demands. This results in lower operating costs, improvements in workplace cleanliness, and reduced downtime for equipment servicing, especially in environments where contamination control is essential.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email