- Home Page

- Company Profile

-

Our Products

- Rubber Rollers

- Textile Printing Rubber Roller

- Cork Rollers

- Film Plant Roller

- Carbon Fiber Roller

- Film Plant Rubber Rolls

- Rubber Groove Spreader Roller

- Etching Roller

- Lamination Roller

- Godded Roller

- Rubber Grooved Spreader Rollers

- Rotogravure Printing Rubber Rollers

- Polyurethane Rubber Roller

- Rubber Coated Rollers

- Quick Change Sleeve Roller

- Rotogravure Printing Roller

- Rubber Roller For Foil

- Lamination Rubber Rollers

- Rubber Spreader Roller

- Rubber Roller for Leather

- Flexo Gravure Printing Rollers

- Industrial Rubber Roller

- Flexographic Rubber Roller

- Rubber Roller

- PU Rubber Roller

- Damping Rubber Roller

- Sucker Muller Rubber Roller

- Impression Rubber Roller

- Solvent Based Lamination Rubber Roller

- Ebonite Rubber Rollers

- Adhesive Coating Rubber Roller

- Intermediate Rubber Roller

- Hollow Rubber Roller

- VMCH Coating Rubber Roller

- Nitrile Rubber Rollers

- Printing Rubber Roller

- Rubber Roller for Tyre-tube

- Hypalon Rubber Rollers

- Tap Line Rubber Roller

- Chemical Resistance Rubber Roller

- EPDM Rubber Rollers

- BOPP Film Plant Rubber Roller

- Jockey Rubber Roller

- Raffia Machine Rubber Rollers

- Solventless Lamination Rubber Roller

- Packaging Rubber Roller

- Industrial Silicone Rubber Roller

- Adhesive Applicator Silicone Rubber Roller

- Hot Stamping Silicone Rubber Roller

- Printing Rubber Rollers

- Rubber Roller PTFE Coated

- Rubber Roller Ptfe Coated

- Flexo Gravure Printing Rubber Roller

- Synthetic Rubber Roller

- Air Shafts

- Carbon Fiber Air Shaft

- Air Shaft

- Quick Lock Shaft

- Core Shaft

- Air Expanding Shafts

- Leaf Type Air Expandable Shaft

- Lug Type Air Expandable Shaft

- Multi Bladder Shaft

- Multi Tube Air Shaft

- Multi Tube Shaft

- Ball Type Quick Lock Shafts

- Metalizer Air Shaft

- Core Air Shaft

- Cantilever Air Shaft

- Industrial Air Shaft

- Mechanical Air Expandable Shaft

- Rubber Expander Roller

- Aluminium or Wooden Slat Expanders

- Rubber Load Roller

- Polyband Expander Roller

- Rubber Expander Roller for Textile Industry

- Textile Rubber Expander Roller

- Curve Bar Expander Roller

- Rubber Expander Roller for Paper Industry

- Rubber Expander Roller

- Liquid Ammonia Expander Roller

- Pop Reel Rubber Expander Roller

- Industrial Textile Expanders

- Liquid Ammonia Rubber Expander Roller

- Rubber Expander Roller For Packaging Industry

- Curved Bar Rubber Expander Roller

- Variable bow roller

- Bow Rollers

- PU Roller

- Safety Chucks

- Embossing Roller

- PTFE Coated Roller

- PTFE Sleeve Coated Roller for Paper Industries

- Rubber Expander Roller with FEP PTFE Sleeve

- Rubber Expander With FEP PTFE Sleeve

- PTFE Expander Roller

- PTFE Coated Rubber Expander

- PTFE Sleeve Expander Roller

- PTFE Sleeve Coated Roller

- PTFE Sleeve Coated Roller For Paper Industries

- PTFE Sleeve Coated Bow Roller

- Air Expanding Shaft

- Hard Chrome Plated Roller

- Steel Rollers

- Banana Roller

- Core Holding Devices

- Air Chuck

- Differential Shafts

- Nip Rollers

- Anilox Roller

- Lock Shafts

- Aluminium Guide Rollers

- Lamination Rubber Roller

- Silicone Rubber Roller

- Rubber Sleeves

- Industrial Rollers

- Industrial Shafts

- Rubber Rollers

-

Applications

- Rubber Roller for Leather Industries

- Rubber Roller for Plastic Industries

- Rubber Roller for Textile Industries

- Rubber Roller for Paper Industries

- Rubber Roller for Metal Industries

- Quality

- Rubber Roller for Packaging Industries

- Rubber Roller for Tyre-tube

- Rubber Roller for Wallpaper Industries

- Infrastructure & Facilities

- Exports

- Infrastructure & Facilities

- Exports

- Contact Us

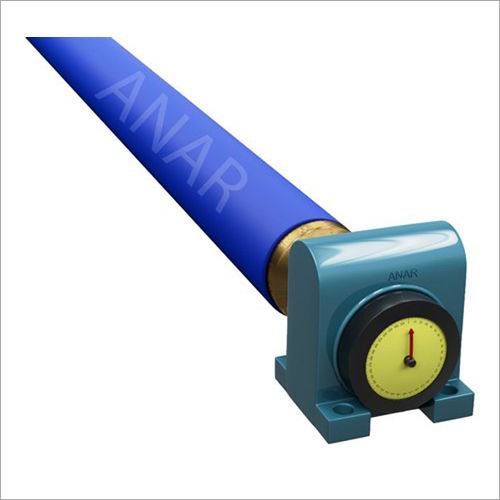

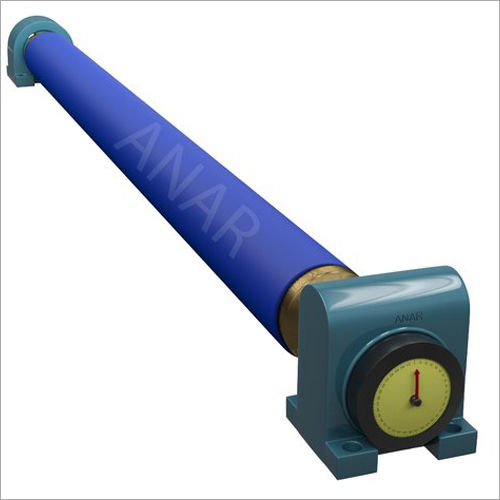

Metallic Bow Roller

10000.00 INR/Piece

Product Details:

- Diameter 100 mm 400 mm

- Capacity Up to 5000 kg

- Material Mild Steel / Stainless Steel / Coated Metal

- Dimensions As per drawing or specification

- Technique Precision Machined & Welded

- Standard Custom, as per requirement

- Belt Width 50 mm 2500 mm

- Click to View more

X

Metallic Bow Roller Price And Quantity

- 10000.00 INR/Piece

- 1 Piece

Metallic Bow Roller Product Specifications

- Precision Machined & Welded

- Custom, as per requirement

- 100 mm 400 mm

- As per drawing or specification

- Up to 5000 kg

- 50 mm 2500 mm

- Corrosion Resistant, Heavy Duty, High Load Capacity

- Mild Steel / Stainless Steel / Coated Metal

Metallic Bow Roller Trade Information

- 2000 Piece Per Month

- 25 Days

Product Description

Metallic Bow Roller offered by us, is quality inspected to ensure that it meets worldwide industrial standards. This bow roller is used to remove wrinkles as well as loose edges and slit separation. Our bow roller is used to make and transform paper, foils, films, plastic Tyrecord, and textiles. Besides, Metallic Bow Roller is noted for its high temperature tolerance, less wear and tear, and greater durability standards, as it is made from premium grade raw materials. Furthermore, we ensure that this roller meets all international criteria.

Technical specification

Roller Length | Customize |

Size | Customize |

Brand | Anar |

Surface Treatment | Hard Chrome |

Packaging Type | Standard |

Color | Silver |

Material | Steel |

Roller Diameter | Customize |

Details

- Material: Metal and Plastic

- Available Sizes: 100-150 mm

- Type: Bow Rolls

Superior Build & Custom Specifications

Our bow rollers are meticulously engineered using premium quality steel and advanced coating techniques, allowing custom diameters (100400 mm) and lengths (3003,500 mm) to meet any industry need. Flanged or plain-end options and the use of precision machined and welded components ensure optimal durability and compatibility.

Versatile Applications Across Industries

Ideal for conveyor systems in textile, paper, and processing units, these bow rollers operate seamlessly across various environments. Their corrosion-resistant, heavy-duty design makes them especially reliable for continuous industrial usage under demanding conditions.

Performance and Longevity

The integration of EN8 or stainless steel shafts and sealed ball bearings guarantees smooth motion, extended service life, and outstanding resistance to rust and environmental wear. Each roller is built to endure high loads and harsh workspaces, empowering your operations productivity.

FAQs of Metallic Bow Roller:

Q: How does the anti-rust coating benefit the metallic bow rollers performance?

A: The anti-rust coating enhances the rollers durability by protecting it from corrosion, especially in humid or chemical-heavy environments, ensuring a longer lifespan and reliable performance in continuous industrial operations.Q: What shaft materials are used and why are they significant?

A: Our bow rollers use EN8 or stainless steel shafts, chosen for their strength and resilience. EN8 offers excellent toughness, while stainless steel provides superior resistance to corrosion, making them suited for a wide array of industrial applications.Q: When should I opt for a flanged end versus a plain end mounting?

A: Flanged ends are recommended when secure, fixed positioning is required for your application, especially in high-load or precision environments. Plain ends are suitable for simpler installations or where quick removal is desired.Q: Where can metallic bow rollers be installed?

A: These rollers are predominantly installed in conveyor systems within textile mills, paper manufacturing plants, and general processing units, but they can be adapted for use in any industry handling heavy or bulky materials.Q: What is the process for customizing the rollers length and coating?

A: Clients provide detailed specifications or drawings indicating required roller length, diameter, and preferred coating or finish. Our manufacturing process then tailors each roller using precision machining and welding techniques to match those specifications.Q: How do sealed ball bearings improve roller operation?

A: Sealed ball bearings reduce friction, prevent dust and contaminants from affecting performance, and contribute to smoother, quieter, and maintenance-free operation, even under high loads or continuous use.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email