- Home Page

- Company Profile

-

Our Products

- Rubber Rollers

- Textile Printing Rubber Roller

- Cork Rollers

- Film Plant Roller

- Carbon Fiber Roller

- Film Plant Rubber Rolls

- Rubber Groove Spreader Roller

- Etching Roller

- Lamination Roller

- Godded Roller

- Rubber Grooved Spreader Rollers

- Rotogravure Printing Rubber Rollers

- Polyurethane Rubber Roller

- Rubber Coated Rollers

- Quick Change Sleeve Roller

- Rotogravure Printing Roller

- Rubber Roller For Foil

- Lamination Rubber Rollers

- Rubber Spreader Roller

- Rubber Roller for Leather

- Flexo Gravure Printing Rollers

- Industrial Rubber Roller

- Flexographic Rubber Roller

- Rubber Roller

- PU Rubber Roller

- Damping Rubber Roller

- Sucker Muller Rubber Roller

- Impression Rubber Roller

- Solvent Based Lamination Rubber Roller

- Ebonite Rubber Rollers

- Adhesive Coating Rubber Roller

- Intermediate Rubber Roller

- Hollow Rubber Roller

- VMCH Coating Rubber Roller

- Nitrile Rubber Rollers

- Printing Rubber Roller

- Rubber Roller for Tyre-tube

- Hypalon Rubber Rollers

- Tap Line Rubber Roller

- Chemical Resistance Rubber Roller

- EPDM Rubber Rollers

- BOPP Film Plant Rubber Roller

- Jockey Rubber Roller

- Raffia Machine Rubber Rollers

- Solventless Lamination Rubber Roller

- Packaging Rubber Roller

- Industrial Silicone Rubber Roller

- Adhesive Applicator Silicone Rubber Roller

- Hot Stamping Silicone Rubber Roller

- Printing Rubber Rollers

- Rubber Roller PTFE Coated

- Rubber Roller Ptfe Coated

- Flexo Gravure Printing Rubber Roller

- Synthetic Rubber Roller

- Air Shafts

- Carbon Fiber Air Shaft

- Air Shaft

- Quick Lock Shaft

- Core Shaft

- Air Expanding Shafts

- Leaf Type Air Expandable Shaft

- Lug Type Air Expandable Shaft

- Multi Bladder Shaft

- Multi Tube Air Shaft

- Multi Tube Shaft

- Ball Type Quick Lock Shafts

- Metalizer Air Shaft

- Core Air Shaft

- Cantilever Air Shaft

- Industrial Air Shaft

- Mechanical Air Expandable Shaft

- Rubber Expander Roller

- Aluminium or Wooden Slat Expanders

- Rubber Load Roller

- Polyband Expander Roller

- Rubber Expander Roller for Textile Industry

- Textile Rubber Expander Roller

- Curve Bar Expander Roller

- Rubber Expander Roller for Paper Industry

- Rubber Expander Roller

- Liquid Ammonia Expander Roller

- Pop Reel Rubber Expander Roller

- Industrial Textile Expanders

- Liquid Ammonia Rubber Expander Roller

- Rubber Expander Roller For Packaging Industry

- Curved Bar Rubber Expander Roller

- Variable bow roller

- Bow Rollers

- PU Roller

- Safety Chucks

- Embossing Roller

- PTFE Coated Roller

- PTFE Sleeve Coated Roller for Paper Industries

- Rubber Expander Roller with FEP PTFE Sleeve

- Rubber Expander With FEP PTFE Sleeve

- PTFE Expander Roller

- PTFE Coated Rubber Expander

- PTFE Sleeve Expander Roller

- PTFE Sleeve Coated Roller

- PTFE Sleeve Coated Roller For Paper Industries

- PTFE Sleeve Coated Bow Roller

- Air Expanding Shaft

- Hard Chrome Plated Roller

- Steel Rollers

- Banana Roller

- Core Holding Devices

- Air Chuck

- Differential Shafts

- Nip Rollers

- Anilox Roller

- Lock Shafts

- Aluminium Guide Rollers

- Lamination Rubber Roller

- Silicone Rubber Roller

- Rubber Sleeves

- Industrial Rollers

- Industrial Shafts

- Rubber Rollers

-

Applications

- Rubber Roller for Leather Industries

- Rubber Roller for Plastic Industries

- Rubber Roller for Textile Industries

- Rubber Roller for Paper Industries

- Rubber Roller for Metal Industries

- Quality

- Rubber Roller for Packaging Industries

- Rubber Roller for Tyre-tube

- Rubber Roller for Wallpaper Industries

- Infrastructure & Facilities

- Exports

- Infrastructure & Facilities

- Exports

- Contact Us

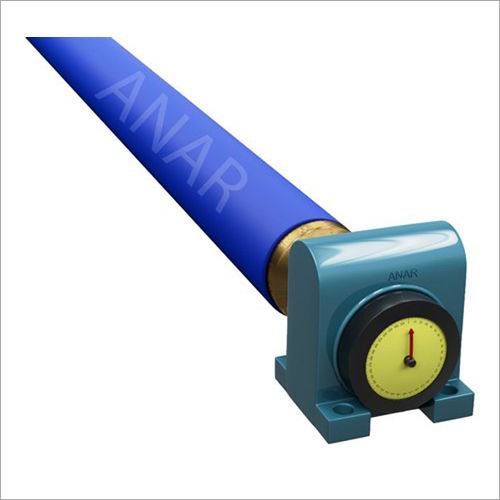

Bow Spreader Roller

10000.00 INR/Piece

Product Details:

- Capacity High Load Bearing

- Diameter 60-150 mm

- Material Aluminium / Stainless Steel / Rubber Coated

- Dimensions Up to 6000 mm length

- Technique Precision Machined, Dynamic Balancing

- Standard Industrial Grade

- Belt Width Customizable as per requirement

- Click to View more

X

Bow Spreader Roller Price And Quantity

- 1 Piece

- 10000.00 INR/Piece

Bow Spreader Roller Product Specifications

- Precision Machined, Dynamic Balancing

- Customizable as per requirement

- 60-150 mm

- High Load Bearing

- Up to 6000 mm length

- Industrial Grade

- Aluminium / Stainless Steel / Rubber Coated

- Wrinkle Removal, Web Guiding, Spreading

Bow Spreader Roller Trade Information

- 2000 Piece Per Month

- 25 Days

Product Description

Technical specification

Packaging Type | Standard |

Brand | Anar |

Usage/Application | Paper Industries,Textile Industries,Film Plant |

Color | Blue,Black |

Temperature | 40 C to 120 C |

Packing Type | Standard |

Engineered for Versatility and Efficiency

Our Bow Spreader Roller is designed with adaptability in mind, making it an ideal choice for diverse industries including textiles, paper, plastics, and laminates. Precision-machined and dynamically balanced, it ensures flawless performance, whether your process involves high speeds or heavy loads. The manually adjustable bow angle provides operators with exceptional control over spreading and guiding functionalities for varied applications.

Customizable Solutions for Every Need

From diameter options (60-150 mm) to lengths up to 6000 mm, the Bow Spreader Roller can be tailored to fit specific process requirements. Choose from different end fittingsmild steel, stainless steel, or aluminiumand select the material and surface finish that best suits your working conditions. Belt width customization further expands the rollers usability across projects of all sizes.

FAQs of Bow Spreader Roller:

Q: How does the bow angle adjustment enhance the rollers performance?

A: The manually adjustable bow angle allows operators to fine-tune the rollers curve, optimizing wrinkle removal, spreading, and web guiding for different materials and applications. This flexibility helps maintain consistent product quality and reduces operational downtime.Q: What industries can benefit from using this bow spreader roller?

A: Industries such as textiles, paper, plastics, and lamination benefit most from this roller, thanks to its capacity for high-speed, high-load operation and its proven effectiveness in web handling processes requiring wrinkle removal and precise guiding.Q: When should I consider using a bow spreader roller in my production line?

A: Consider implementing a bow spreader roller whenever your production process involves handling flat webs or sheets that require wrinkle prevention, web alignment, or material spreadingespecially at higher speeds or with wider material widths.Q: Where can the roller be installed within an industrial system?

A: The rollers both-side bearing-mounted design facilitates straightforward integration at key web handling points, such as entry or exit zones, or wherever wrinkle issues and web misalignments commonly occur during production.Q: What is the maximum belt width and length that can be accommodated?

A: The bow spreader roller can be customized to handle a wide range of belt widths and supports lengths up to 6000 mm, offering scalability for small to large-scale operations.Q: How is the roller manufactured for optimal durability and precision?

A: Utilizing precision machining and dynamic balancing techniques, each roller is crafted from high-grade aluminium, stainless steel, or rubber-coated materials. This process ensures durability, smooth operation, and longevity under demanding industrial conditions.Q: What benefits does the surface finish provide to the productivity of the roller?

A: A smooth or anodized surface finish reduces friction, prevents material buildup, and enhances cleanliness, thereby ensuring consistent web handling, minimizing maintenance needs, and extending the lifespan of the roller.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email