- Home Page

- Company Profile

-

Our Products

- Rubber Rollers

- Textile Printing Rubber Roller

- Cork Rollers

- Film Plant Roller

- Carbon Fiber Roller

- Film Plant Rubber Rolls

- Rubber Groove Spreader Roller

- Etching Roller

- Lamination Roller

- Godded Roller

- Rubber Grooved Spreader Rollers

- Rotogravure Printing Rubber Rollers

- Polyurethane Rubber Roller

- Rubber Coated Rollers

- Quick Change Sleeve Roller

- Rotogravure Printing Roller

- Rubber Roller For Foil

- Lamination Rubber Rollers

- Rubber Spreader Roller

- Rubber Roller for Leather

- Flexo Gravure Printing Rollers

- Industrial Rubber Roller

- Flexographic Rubber Roller

- Rubber Roller

- PU Rubber Roller

- Damping Rubber Roller

- Sucker Muller Rubber Roller

- Impression Rubber Roller

- Solvent Based Lamination Rubber Roller

- Ebonite Rubber Rollers

- Adhesive Coating Rubber Roller

- Intermediate Rubber Roller

- Hollow Rubber Roller

- VMCH Coating Rubber Roller

- Nitrile Rubber Rollers

- Printing Rubber Roller

- Rubber Roller for Tyre-tube

- Hypalon Rubber Rollers

- Tap Line Rubber Roller

- Chemical Resistance Rubber Roller

- EPDM Rubber Rollers

- BOPP Film Plant Rubber Roller

- Jockey Rubber Roller

- Raffia Machine Rubber Rollers

- Solventless Lamination Rubber Roller

- Packaging Rubber Roller

- Industrial Silicone Rubber Roller

- Adhesive Applicator Silicone Rubber Roller

- Hot Stamping Silicone Rubber Roller

- Printing Rubber Rollers

- Rubber Roller PTFE Coated

- Rubber Roller Ptfe Coated

- Flexo Gravure Printing Rubber Roller

- Synthetic Rubber Roller

- Air Shafts

- Carbon Fiber Air Shaft

- Air Shaft

- Quick Lock Shaft

- Core Shaft

- Air Expanding Shafts

- Leaf Type Air Expandable Shaft

- Lug Type Air Expandable Shaft

- Multi Bladder Shaft

- Multi Tube Air Shaft

- Multi Tube Shaft

- Ball Type Quick Lock Shafts

- Metalizer Air Shaft

- Core Air Shaft

- Cantilever Air Shaft

- Industrial Air Shaft

- Mechanical Air Expandable Shaft

- Rubber Expander Roller

- Aluminium or Wooden Slat Expanders

- Rubber Load Roller

- Polyband Expander Roller

- Rubber Expander Roller for Textile Industry

- Textile Rubber Expander Roller

- Curve Bar Expander Roller

- Rubber Expander Roller for Paper Industry

- Rubber Expander Roller

- Liquid Ammonia Expander Roller

- Pop Reel Rubber Expander Roller

- Industrial Textile Expanders

- Liquid Ammonia Rubber Expander Roller

- Rubber Expander Roller For Packaging Industry

- Curved Bar Rubber Expander Roller

- Variable bow roller

- Bow Rollers

- PU Roller

- Safety Chucks

- Embossing Roller

- PTFE Coated Roller

- PTFE Sleeve Coated Roller for Paper Industries

- Rubber Expander Roller with FEP PTFE Sleeve

- Rubber Expander With FEP PTFE Sleeve

- PTFE Expander Roller

- PTFE Coated Rubber Expander

- PTFE Sleeve Expander Roller

- PTFE Sleeve Coated Roller

- PTFE Sleeve Coated Roller For Paper Industries

- PTFE Sleeve Coated Bow Roller

- Air Expanding Shaft

- Hard Chrome Plated Roller

- Steel Rollers

- Banana Roller

- Core Holding Devices

- Air Chuck

- Differential Shafts

- Nip Rollers

- Anilox Roller

- Lock Shafts

- Aluminium Guide Rollers

- Lamination Rubber Roller

- Silicone Rubber Roller

- Rubber Sleeves

- Industrial Rollers

- Industrial Shafts

- Rubber Rollers

-

Applications

- Rubber Roller for Leather Industries

- Rubber Roller for Plastic Industries

- Rubber Roller for Textile Industries

- Rubber Roller for Paper Industries

- Rubber Roller for Metal Industries

- Quality

- Rubber Roller for Packaging Industries

- Rubber Roller for Tyre-tube

- Rubber Roller for Wallpaper Industries

- Infrastructure & Facilities

- Exports

- Infrastructure & Facilities

- Exports

- Contact Us

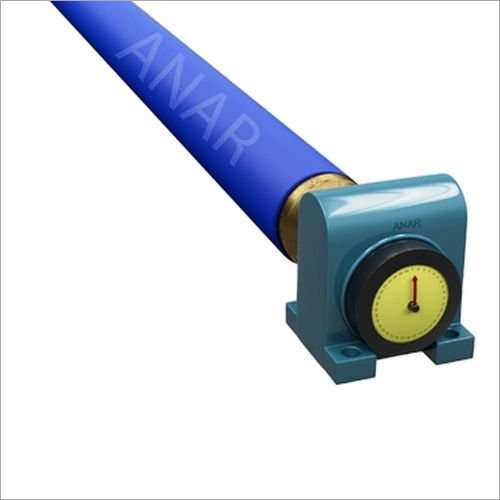

PTFE Sleeve Coated Roller For Paper Industries

48500.00 MXN ($)/Piece

Product Details:

- Diameter 25 mm to 600 mm

- Capacity Custom-built as per application

- Material PTFE (Polytetrafluoroethylene) coated on stainless steel / MS roller

- Dimensions Custom sizes available

- Technique Heat resistant coating process

- Standard ASTM D3308 / IS: 14620

- Belt Width Up to 4000 mm

- Click to View more

X

PTFE Sleeve Coated Roller For Paper Industries Price And Quantity

- 48500.00 MXN ($)/Piece

- 1 Piece

PTFE Sleeve Coated Roller For Paper Industries Product Specifications

- Excellent non-stick, high chemical resistance, high temperature tolerance, low friction

- Up to 4000 mm

- Custom-built as per application

- Custom sizes available

- PTFE (Polytetrafluoroethylene) coated on stainless steel / MS roller

- Heat resistant coating process

- 25 mm to 600 mm

- ASTM D3308 / IS: 14620

PTFE Sleeve Coated Roller For Paper Industries Trade Information

- 5000 Piece Per Month

- 3 Week

Product Description

Technical specification

Usage | Industrial |

Usage/Application | Paper Industries |

Roller Material | Mild Steel |

Roller Length | 800-1000 mm |

Shaft Material | M.S |

Shaft Diameter | Customize |

Condition | New |

Brand | Anar |

Color | Green,Orange |

Packaging Type | Standard |

Roller Materials | Teflon |

Roller Diameter | >80 m |

Unmatched Non-Stick Performance

Featuring PTFE coating, these rollers resist sticky residues common in paper processing. The ultra-smooth, high-gloss finish minimizes friction, boosts production efficiency, and ensures superior paper quality.

Custom-Built for Paper Industry Needs

Available in a range of diameters, lengths, and belt widths to suit varied paper machine applications. Each roller is manufactured to meet strict tolerances and international standards, ensuring consistent performance and reliability.

Durability and Easy Maintenance

PTFEs chemical resistance ensures prolonged lifespan and virtually corrosion-free operation. The rollers design greatly reduces maintenance requirements, lowering downtime and operational costs in busy industrial settings.

FAQs of PTFE Sleeve Coated Roller For Paper Industries:

Q: How is the PTFE Sleeve Coated Roller installed in a paper machine?

A: The roller is fitted into the sizing, calendering, or drying sections using standard mounting techniques, with custom dimensions and tolerances ensuring seamless integration into various paper machine types.Q: What are the key benefits of using PTFE-coated rollers in paper industries?

A: These rollers offer excellent non-stick properties, resist chemicals and high temperatures, have low friction, and are easy to maintain due to their corrosion-free surface, resulting in improved paper quality and operational efficiency.Q: When should I consider replacing or refurbishing a PTFE Sleeve Coated Roller?

A: Replacement or refurbishment is recommended if the coating shows visible signs of wear, loss of gloss, increased sticking, or if tolerance levels exceed the limit of 0.05 mm. Regular inspections help maintain optimal performance.Q: Where can PTFE Sleeve Coated Rollers be used within the paper manufacturing process?

A: They are utilized in sizing, calendering, drying, and other sections where smooth, non-stick, and heat-resistant roller surfaces are required to improve paper finish and minimize material build-up.Q: What is the typical process for manufacturing these rollers?

A: The rollers are produced by applying a heat-resistant PTFE coating using specialized techniques to achieve the desired thickness (0.1 mm to 2 mm) on mild steel or stainless steel cores, ensuring a high-gloss, smooth surface finish.Q: How does the PTFE sleeve ensure low maintenance requirements?

A: PTFEs high chemical resistance and corrosion-free properties prevent degradation from harsh process chemicals or moisture, drastically reducing cleaning frequency and maintenance efforts.Q: Can the roller dimensions, color, or hardness be customized for specific paper machine requirements?

A: Yes, the rollers can be custom-built with tailored dimensions, colors, and hardness between 35 and 60 Shore D to match particular applications, machine sizes, and customer preferences.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email