- Home Page

- Company Profile

-

Our Products

- Rubber Rollers

- Carbon Fiber Roller

- Film Plant Rubber Rolls

- Film Plant Roller

- Textile Printing Rubber Roller

- Cork Rollers

- Lamination Roller

- Rubber Groove Spreader Roller

- Etching Roller

- Rubber Grooved Spreader Rollers

- Polyurethane Rubber Roller

- Rubber Coated Rollers

- Quick Change Sleeve Roller

- Rotogravure Printing Rubber Rollers

- Godded Roller

- Rotogravure Printing Roller

- Rubber Roller For Foil

- Lamination Rubber Rollers

- Rubber Spreader Roller

- Rubber Roller for Leather

- Flexo Gravure Printing Rollers

- Industrial Rubber Roller

- Flexographic Rubber Roller

- Rubber Roller

- Damping Rubber Roller

- PU Rubber Roller

- Sucker Muller Rubber Roller

- Impression Rubber Roller

- Solvent Based Lamination Rubber Roller

- Ebonite Rubber Rollers

- Adhesive Coating Rubber Roller

- Intermediate Rubber Roller

- Hollow Rubber Roller

- VMCH Coating Rubber Roller

- Nitrile Rubber Rollers

- Printing Rubber Roller

- Rubber Roller for Tyre-tube

- Hypalon Rubber Rollers

- Tap Line Rubber Roller

- Chemical Resistance Rubber Roller

- EPDM Rubber Rollers

- BOPP Film Plant Rubber Roller

- Jockey Rubber Roller

- Raffia Machine Rubber Rollers

- Solventless Lamination Rubber Roller

- Packaging Rubber Roller

- Industrial Silicone Rubber Roller

- Adhesive Applicator Silicone Rubber Roller

- Hot Stamping Silicone Rubber Roller

- Printing Rubber Rollers

- Rubber Roller PTFE Coated

- Rubber Roller Ptfe Coated

- Flexo Gravure Printing Rubber Roller

- Synthetic Rubber Roller

- Air Shafts

- Air Shaft

- Carbon Fiber Air Shaft

- Quick Lock Shaft

- Core Shaft

- Air Expanding Shafts

- Leaf Type Air Expandable Shaft

- Lug Type Air Expandable Shaft

- Multi Bladder Shaft

- Multi Tube Air Shaft

- Multi Tube Shaft

- Ball Type Quick Lock Shafts

- Metalizer Air Shaft

- Core Air Shaft

- Cantilever Air Shaft

- Industrial Air Shaft

- Mechanical Air Expandable Shaft

- Rubber Expander Roller

- Aluminium or Wooden Slat Expanders

- Rubber Load Roller

- Polyband Expander Roller

- Rubber Expander Roller for Textile Industry

- Textile Rubber Expander Roller

- Curve Bar Expander Roller

- Rubber Expander Roller for Paper Industry

- Liquid Ammonia Expander Roller

- Rubber Expander Roller

- Industrial Textile Expanders

- Pop Reel Rubber Expander Roller

- Liquid Ammonia Rubber Expander Roller

- Rubber Expander Roller For Packaging Industry

- Curved Bar Rubber Expander Roller

- Variable bow roller

- Bow Rollers

- PU Roller

- Safety Chucks

- Embossing Roller

- PTFE Coated Roller

- PTFE Sleeve Coated Roller for Paper Industries

- Rubber Expander Roller with FEP PTFE Sleeve

- Rubber Expander With FEP PTFE Sleeve

- PTFE Expander Roller

- PTFE Coated Rubber Expander

- PTFE Sleeve Expander Roller

- PTFE Sleeve Coated Roller

- PTFE Sleeve Coated Roller For Paper Industries

- PTFE Sleeve Coated Bow Roller

- Air Expanding Shaft

- Hard Chrome Plated Roller

- Steel Rollers

- Banana Roller

- Core Holding Devices

- Air Chuck

- Differential Shafts

- Nip Rollers

- Anilox Roller

- Lock Shafts

- Aluminium Guide Rollers

- Lamination Rubber Roller

- Silicone Rubber Roller

- Rubber Sleeves

- Industrial Rollers

- Industrial Shafts

- Rubber Rollers

-

Applications

- Rubber Roller for Leather Industries

- Rubber Roller for Plastic Industries

- Rubber Roller for Textile Industries

- Rubber Roller for Paper Industries

- Rubber Roller for Metal Industries

- Quality

- Rubber Roller for Packaging Industries

- Rubber Roller for Tyre-tube

- Rubber Roller for Wallpaper Industries

- Infrastructure & Facilities

- Exports

- Infrastructure & Facilities

- Exports

- Contact Us

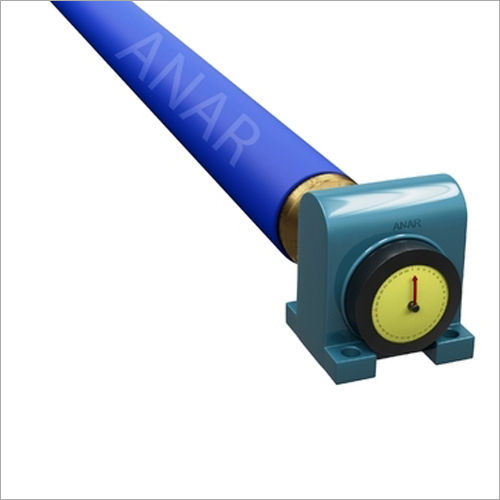

Rubber Expander With FEP PTFE Sleeve

4000.00 - 24000.00 INR/Piece

Product Details:

- Capacity Customizable as per requirement

- Diameter 25 mm to 300 mm

- Material Rubber core with FEP/PTFE sleeve

- Dimensions Customizable length and diameter

- Technique Moulded and precision machined

- Standard Industrial Grade

- Belt Width 150 mm to 2000 mm

- Click to View more

X

Rubber Expander With FEP PTFE Sleeve Price And Quantity

- 4000.00 - 24000.00 INR/Piece

- 1 Piece

Rubber Expander With FEP PTFE Sleeve Product Specifications

- Customizable as per requirement

- Chemical Resistant, Non-stick, High Tensile Strength

- Rubber core with FEP/PTFE sleeve

- 25 mm to 300 mm

- Moulded and precision machined

- Customizable length and diameter

- Industrial Grade

- 150 mm to 2000 mm

Rubber Expander With FEP PTFE Sleeve Trade Information

- 500 Piece Per Month

- 21 Days

Product Description

Technical details

Roller Length | Customized |

Brand | Anar |

Usage/Application | Paper Industry |

Application | Paper Industries |

Coating | Teflon |

Material | FEP Teflon |

Size | Depend on requirement |

Roller Diameter | Customized |

Exceptional Chemical Resistance

Thanks to the fully covered FEP/PTFE sleeve, this rubber expander is highly resistant to harsh chemicals and solvents, providing long-lasting performance in aggressive industrial settings. Its non-porous construction prevents material buildup and ensures easy cleaning, supporting reliable operation in processing lines and challenging environments.

Precision-Engineered for Versatility

Manufactured using precise moulding and machining techniques, these expanders can be tailored in length and diameter to match your specific operational needs. This flexibility ensures optimal performance in conveyor belt systems, textile machines, and other industrial applications, making it a versatile solution compatible with various belt widths and configurations.

Reliable Performance in Diverse Conditions

Designed to operate efficiently between -20C and +200C and resist up to 7 kg/cm pressure, this expander delivers consistent, non-stick functioning even under high thermal and mechanical stress. Its robust construction and smooth surface finish contribute to reduced maintenance and increased service life, supporting uninterrupted productivity.

FAQs of Rubber Expander With FEP PTFE Sleeve:

Q: How is the Rubber Expander with FEP/PTFE Sleeve installed in conveyor systems?

A: The expander is integrated into conveyor belt systems by aligning its diameter and length to the belt width and required tension. Proper installation involves securing the unit in compatible mounts or brackets, ensuring the fully covered sleeve is exposed to the material flow for effective non-stick performance.Q: What benefits does the FEP/PTFE sleeve provide?

A: The FEP/PTFE sleeve delivers outstanding chemical and corrosion resistance, prevents material sticking (non-stick feature), and ensures smooth surface finish. This enhances cleaning, reduces downtime, and extends the expanders lifespan in harsh industrial environments.Q: Where are these expanders most commonly used?

A: These expanders are widely utilized in conveyor belt systems, textile manufacturing, printing presses, and packaging industries due to their resilience against chemicals, high temperatures, and mechanical wear.Q: When should I select a rubber expander with a hardness of 50 to 70 Shore A?

A: A hardness of 50 to 70 Shore A is optimal when moderate flexibility and strength are required, such as in applications that demand high tensile strength yet need to accommodate occasional vibrations and dynamic forces.Q: What is the process for customizing the expanders dimensions?

A: Customization involves specifying required belt width, length, diameter, and sleeve thickness. The manufacturer then moulds and precisely machines the expander to fit the provided specifications, ensuring a tailored solution for each application.Q: How does the expander perform at high temperatures or under pressure?

A: Designed for temperatures from -20C to +200C and pressures up to 7 kg/cm, the expander maintains mechanical robustness and chemical integrity, ensuring consistent performance in extreme industrial conditions.Q: What industries benefit most from using FEP/PTFE-sleeved rubber expanders?

A: Industries such as textiles, conveyor manufacturing, printing, and packaging gain significant advantages, particularly in processes where exposure to chemicals or solvents and the need for consistent, non-stick handling are paramount.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email