- Home Page

- Company Profile

-

Our Products

- Rubber Rollers

- Carbon Fiber Roller

- Film Plant Rubber Rolls

- Film Plant Roller

- Rubber Groove Spreader Roller

- Lamination Roller

- Etching Roller

- Textile Printing Rubber Roller

- Cork Rollers

- Rotogravure Printing Rubber Rollers

- Godded Roller

- Polyurethane Rubber Roller

- Rubber Coated Rollers

- Rubber Grooved Spreader Rollers

- Quick Change Sleeve Roller

- Rotogravure Printing Roller

- Lamination Rubber Rollers

- Rubber Roller For Foil

- Rubber Spreader Roller

- Rubber Roller for Leather

- Industrial Rubber Roller

- Flexo Gravure Printing Rollers

- Flexographic Rubber Roller

- Rubber Roller

- Damping Rubber Roller

- PU Rubber Roller

- Sucker Muller Rubber Roller

- Impression Rubber Roller

- Solvent Based Lamination Rubber Roller

- Ebonite Rubber Rollers

- Adhesive Coating Rubber Roller

- Intermediate Rubber Roller

- Hollow Rubber Roller

- VMCH Coating Rubber Roller

- Nitrile Rubber Rollers

- Printing Rubber Roller

- Rubber Roller for Tyre-tube

- Hypalon Rubber Rollers

- Tap Line Rubber Roller

- Chemical Resistance Rubber Roller

- EPDM Rubber Rollers

- BOPP Film Plant Rubber Roller

- Jockey Rubber Roller

- Raffia Machine Rubber Rollers

- Solventless Lamination Rubber Roller

- Packaging Rubber Roller

- Industrial Silicone Rubber Roller

- Adhesive Applicator Silicone Rubber Roller

- Hot Stamping Silicone Rubber Roller

- Printing Rubber Rollers

- Rubber Roller PTFE Coated

- Rubber Roller Ptfe Coated

- Flexo Gravure Printing Rubber Roller

- Synthetic Rubber Roller

- Air Shafts

- Air Shaft

- Carbon Fiber Air Shaft

- Quick Lock Shaft

- Core Shaft

- Air Expanding Shafts

- Leaf Type Air Expandable Shaft

- Lug Type Air Expandable Shaft

- Multi Bladder Shaft

- Multi Tube Air Shaft

- Multi Tube Shaft

- Ball Type Quick Lock Shafts

- Metalizer Air Shaft

- Core Air Shaft

- Cantilever Air Shaft

- Industrial Air Shaft

- Mechanical Air Expandable Shaft

- Rubber Expander Roller

- Aluminium or Wooden Slat Expanders

- Rubber Load Roller

- Polyband Expander Roller

- Rubber Expander Roller for Textile Industry

- Textile Rubber Expander Roller

- Curve Bar Expander Roller

- Rubber Expander Roller for Paper Industry

- Liquid Ammonia Expander Roller

- Rubber Expander Roller

- Industrial Textile Expanders

- Pop Reel Rubber Expander Roller

- Liquid Ammonia Rubber Expander Roller

- Rubber Expander Roller For Packaging Industry

- Curved Bar Rubber Expander Roller

- Variable bow roller

- Bow Rollers

- PU Roller

- Safety Chucks

- Embossing Roller

- PTFE Coated Roller

- PTFE Sleeve Coated Roller for Paper Industries

- Rubber Expander Roller with FEP PTFE Sleeve

- Rubber Expander With FEP PTFE Sleeve

- PTFE Expander Roller

- PTFE Coated Rubber Expander

- PTFE Sleeve Expander Roller

- PTFE Sleeve Coated Roller

- PTFE Sleeve Coated Roller For Paper Industries

- PTFE Sleeve Coated Bow Roller

- Air Expanding Shaft

- Hard Chrome Plated Roller

- Steel Rollers

- Banana Roller

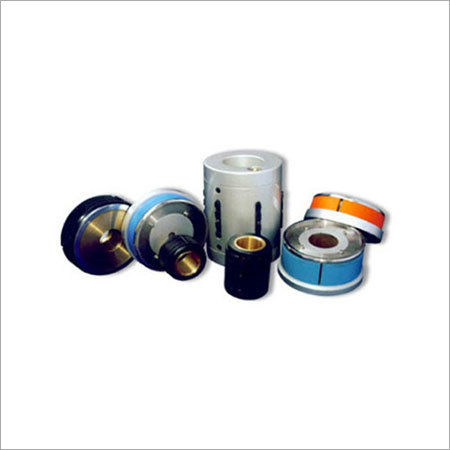

- Core Holding Devices

- Air Chuck

- Differential Shafts

- Nip Rollers

- Anilox Roller

- Lock Shafts

- Aluminium Guide Rollers

- Lamination Rubber Roller

- Silicone Rubber Roller

- Rubber Sleeves

- Industrial Rollers

- Industrial Shafts

- Rubber Rollers

-

Applications

- Rubber Roller for Leather Industries

- Rubber Roller for Plastic Industries

- Rubber Roller for Textile Industries

- Rubber Roller for Paper Industries

- Rubber Roller for Metal Industries

- Quality

- Rubber Roller for Packaging Industries

- Rubber Roller for Tyre-tube

- Rubber Roller for Wallpaper Industries

- Infrastructure & Facilities

- Exports

- Infrastructure & Facilities

- Exports

- Contact Us

X

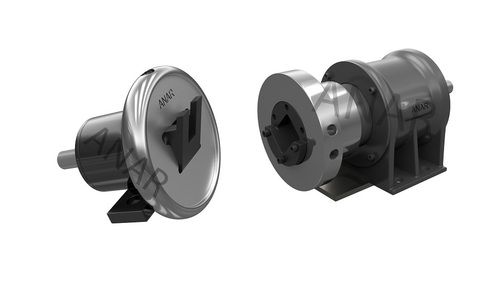

Tilt Type Safety Chuck Price And Quantity

- 1 , , Piece

- 25000 INR/Piece

Tilt Type Safety Chuck Product Specifications

- Other

Tilt Type Safety Chuck Trade Information

- Mundra

- 500 , , Piece Per Month

- 21 Days

- Standard

Product Description

Tilt Type Safety Chuck is a square bar holder that is mostly utilised in shafted centre winding and unwinding applications. Each chuck goes through many steps to ensure best-in-class quality and minimum maintenance. We are constantly devoted to offering our clients with on-time delivery and 24*7 service assistance. Our provided Tilt Type Safety Chuck may now be outfitted with mechanical and electromechanical sensors that can detect whether the safety chuck is open or closed, significantly boosting safety. This is widely appreciated by our clients, in the market.

Technical specification

Minimum Order Quantity | 1 Piece |

Brand | Anar Rub Tech |

Model | ART-4933 |

Material | C.I |

Condition | New |

Color | Black |

Mounting | Wall and Foot |

Quantity Per Pack | One |

Reliable Safety Mechanism

The self-locking slot design incorporated into our Tilt Type Safety Chuck offers enhanced operational security by preventing accidental disengagement during use. This feature is especially beneficial in high-speed industrial applications, reducing the risk of shaft slippage and promoting a safer working environment.

Durable & Versatile Construction

Built with hardened tool steel jaws and a corrosion-resistant coating, this safety chuck is engineered to withstand demanding industrial conditions. It is compatible with both flange and foot mounting, and suitable for various shaft types including expanding and air shafts, providing adaptability for a range of applications.

FAQs of Tilt Type Safety Chuck:

Q: How does the self-locking slot mechanism enhance the safety of the safety chuck?

A: The self-locking slot mechanism ensures that the shaft remains securely engaged during operation. It automatically locks the shaft in place, preventing accidental release or disengagement, thereby providing a safer working environment and reducing the risk of machinery-related incidents.Q: What are the mounting options available for this safety chuck?

A: This safety chuck is available with both flange mount and foot mount options, allowing for flexible installation to suit different machine designs and operational requirements.Q: When should I consider using a tilt type safety chuck in my application?

A: A tilt type safety chuck is ideal when frequent shaft changes are necessary or when operational safety is paramount, especially in industries like textile, printing, packaging, and lamination that require efficient roll handling and secure shaft mounting.Q: Where can the tilt type safety chuck be applied effectively?

A: The safety chuck is widely used in industrial settings such as textile processing, printing presses, packaging lines, paper manufacturing, and lamination plants. It is well-suited for both new installations and equipment retrofits across these sectors.Q: What maintenance is required for this safety chuck, and how often should it be performed?

A: The unit is designed for low maintenance. Routine periodic inspections are recommended to check for wear and ensure proper functioning of the locking slot and jaws. Lubrication and cleaning may be required occasionally, depending on the working environment.Q: How does the corrosion-resistant coating benefit the safety chuck?

A: The corrosion-resistant finish protects the safety chuck from environmental and chemical damage, extending its service life and reducing the frequency of required maintenance, even in humid or harsh industrial environments.Q: Which shaft types are compatible with this safety chuck, and what is the maximum shaft size?

A: This safety chuck is compatible with expanding shafts and air shafts, accommodating shaft inserts up to 38 mm square. This versatility ensures it can handle a wide spectrum of roll handling applications across various industries.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email